Automatic pipe pressure experiment device

A kind of experimental equipment and pipe technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., which can solve the problems of manual installation of fixtures, inconvenience, and long experiment cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

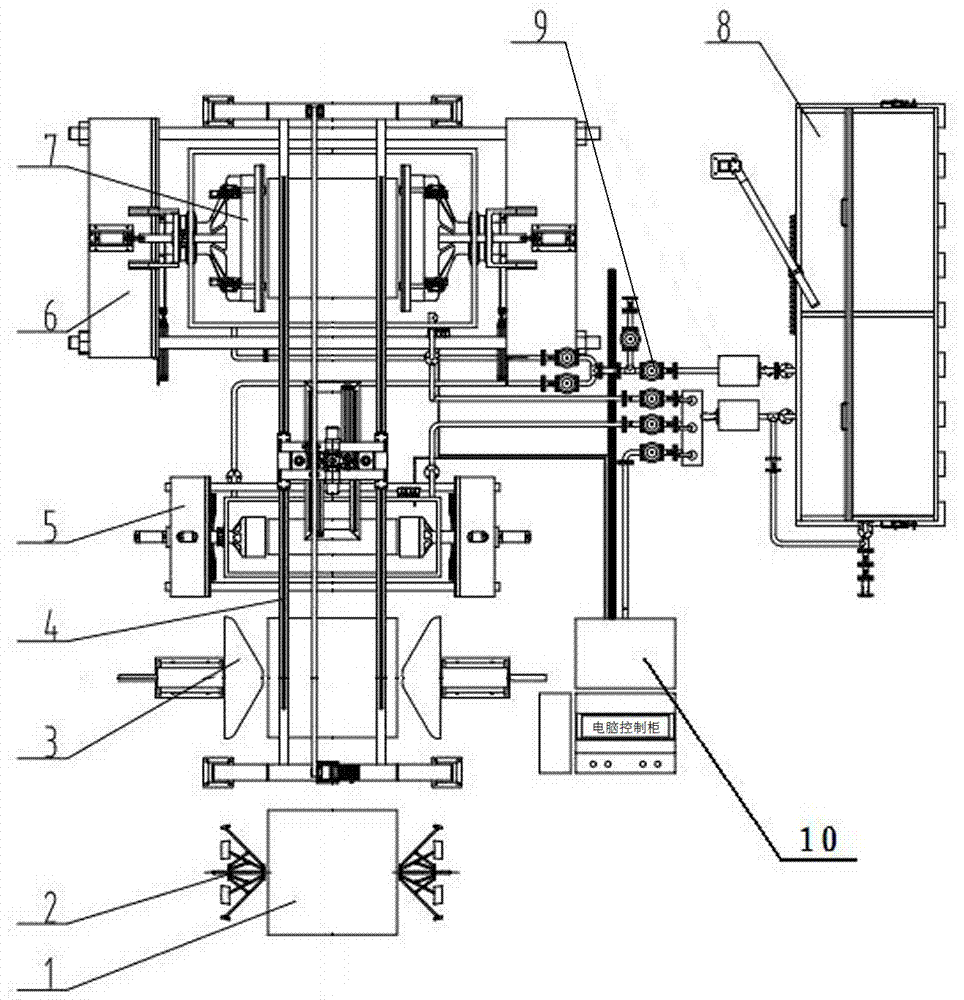

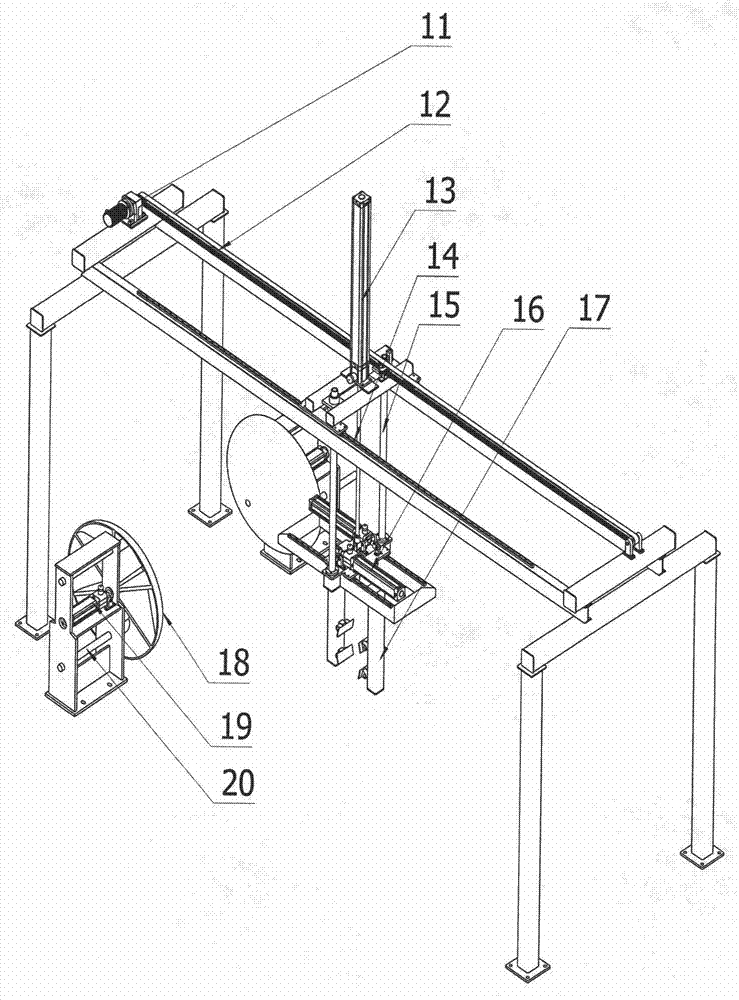

[0015] Such as figure 1 As shown, the automatic pipe pressure test device includes an inner wall support device 2, a centering device 3, a hoisting device 4, a small-size test box 5, a large-size test box 6, a sealing device 7, an insulated water storage tank 8, pipelines 9 and electrical appliances. 10 main components of the temperature control system. The inner wall supporting device 2 adopts a nut screw structure, one end of the screw is connected with the fixed plate of the long arm through a bearing, one end is connected with the hand wheel, one end of the short arm is hinged with the nut, and the other end is hinged with the long arm. The centering disc 18 in the centering device 3 is connected to the cylinder 19, one end of the guide rod 20 is connected to the centering disc 18 through a screw, and the other end passes through the support. In the hoisting device 4, the motor 11 is installed on the fixed crossbeam, and the moving crossbeam is driven to move by the belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com