Carbon Fiber Multiaxial Vibration Spreading Device

A multi-axial, carbon fiber technology, applied in the direction of textiles and papermaking, to achieve the effect of increasing the unfolded area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

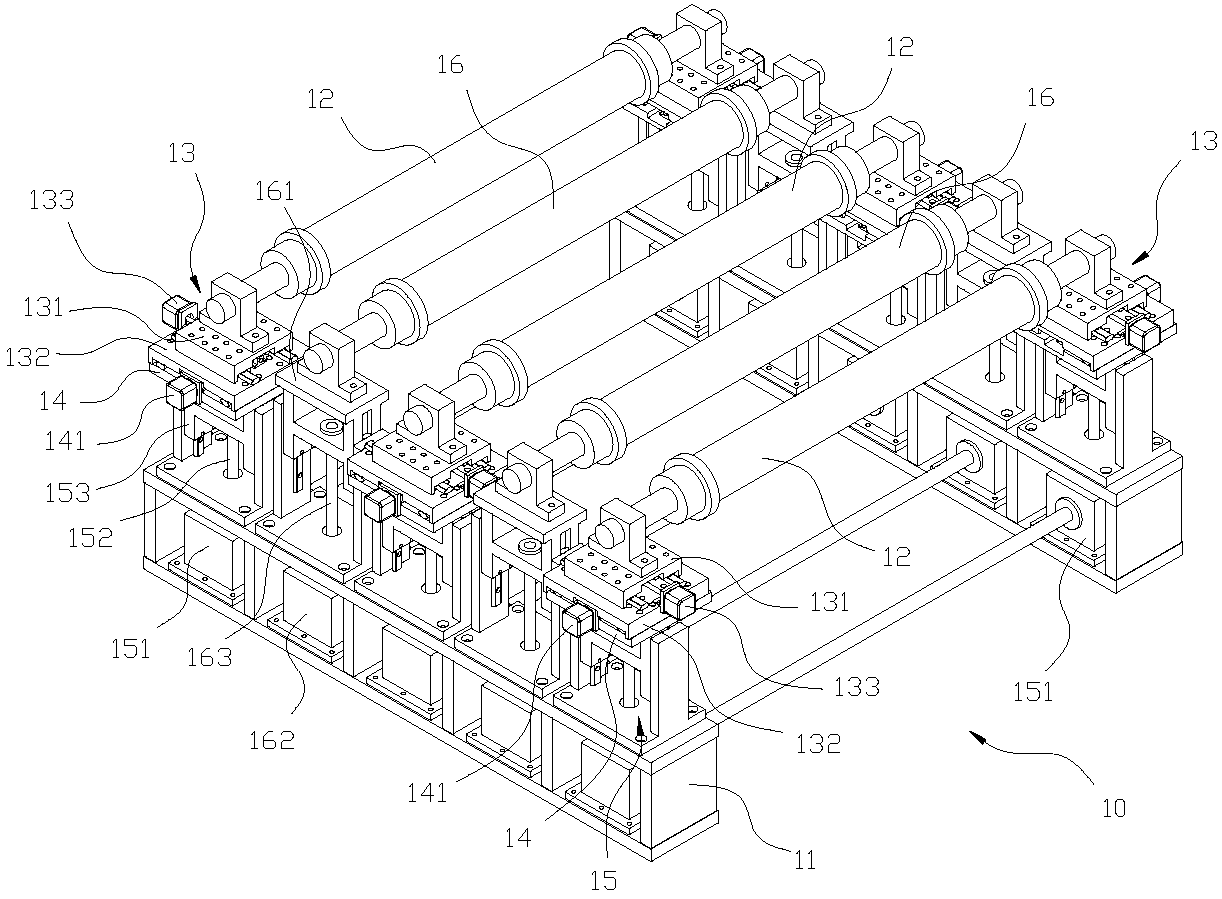

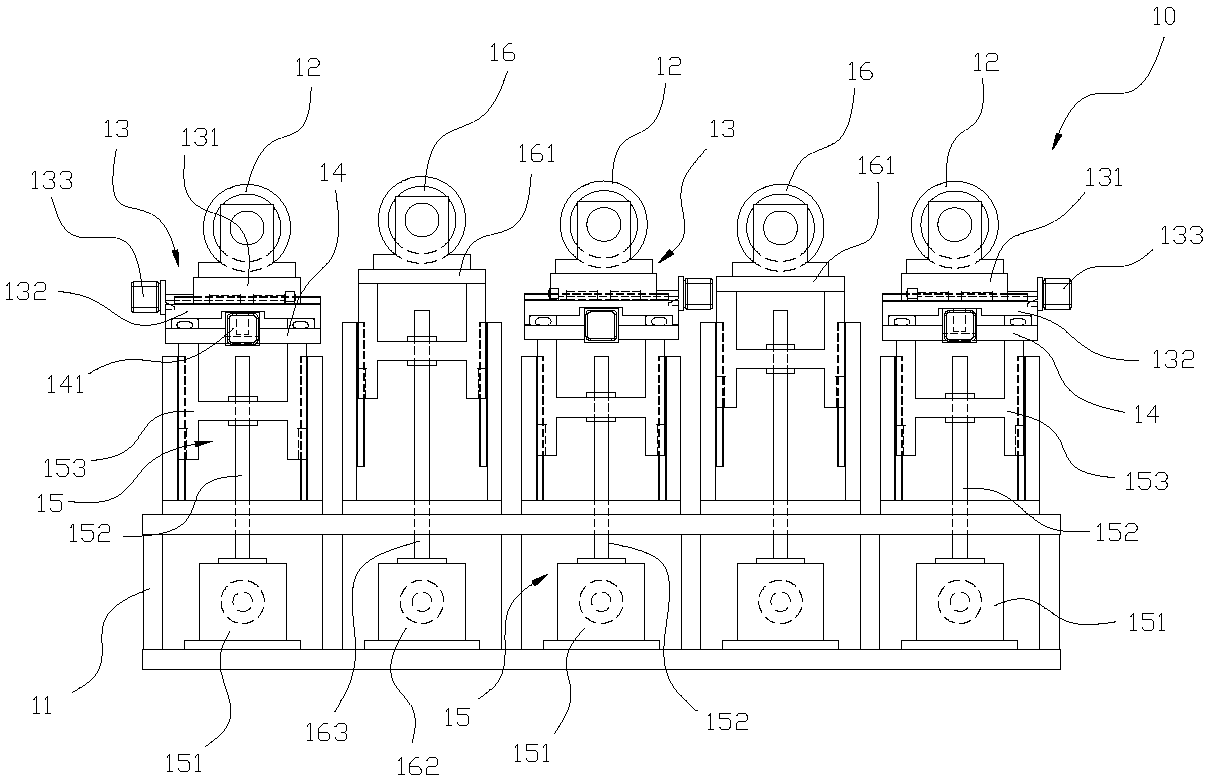

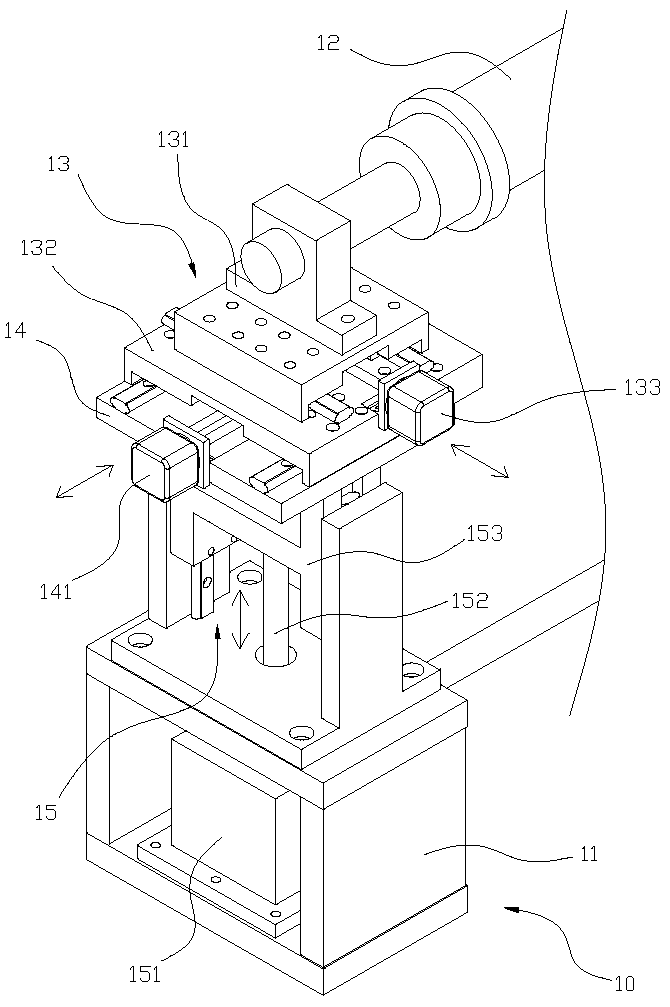

[0045] first please Figure 1 to Figure 3 As shown, the present invention provides a carbon fiber multi-axial vibration spreading device, wherein: a spreading device 10 is arranged in parallel with a plurality of spreading wheels 12 with a frame body 11, and the spreading device 10 uses a plurality of first An actuator 13 independently pivots the plurality of yarn spreading wheels 12, and the first actuator 13 drives the yarn spreading wheels 12 to perform one axial displacement of reciprocating back and forth, reciprocating left and right, or reciprocating up and down relative to the frame body 11. In the yarn spreading device 10, multiple second actuators 14 are independently co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com