Lining cloth adhesion method

A technology for interlining and lining, which is applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of different shapes of linings, large manpower, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

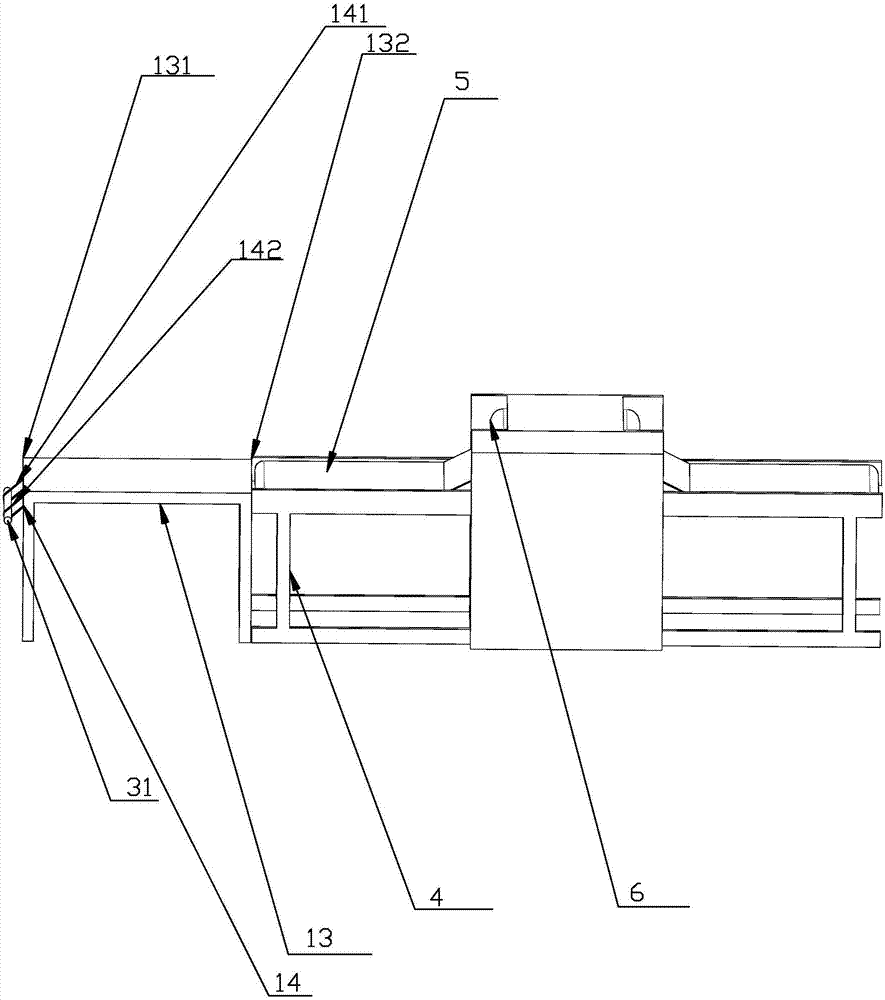

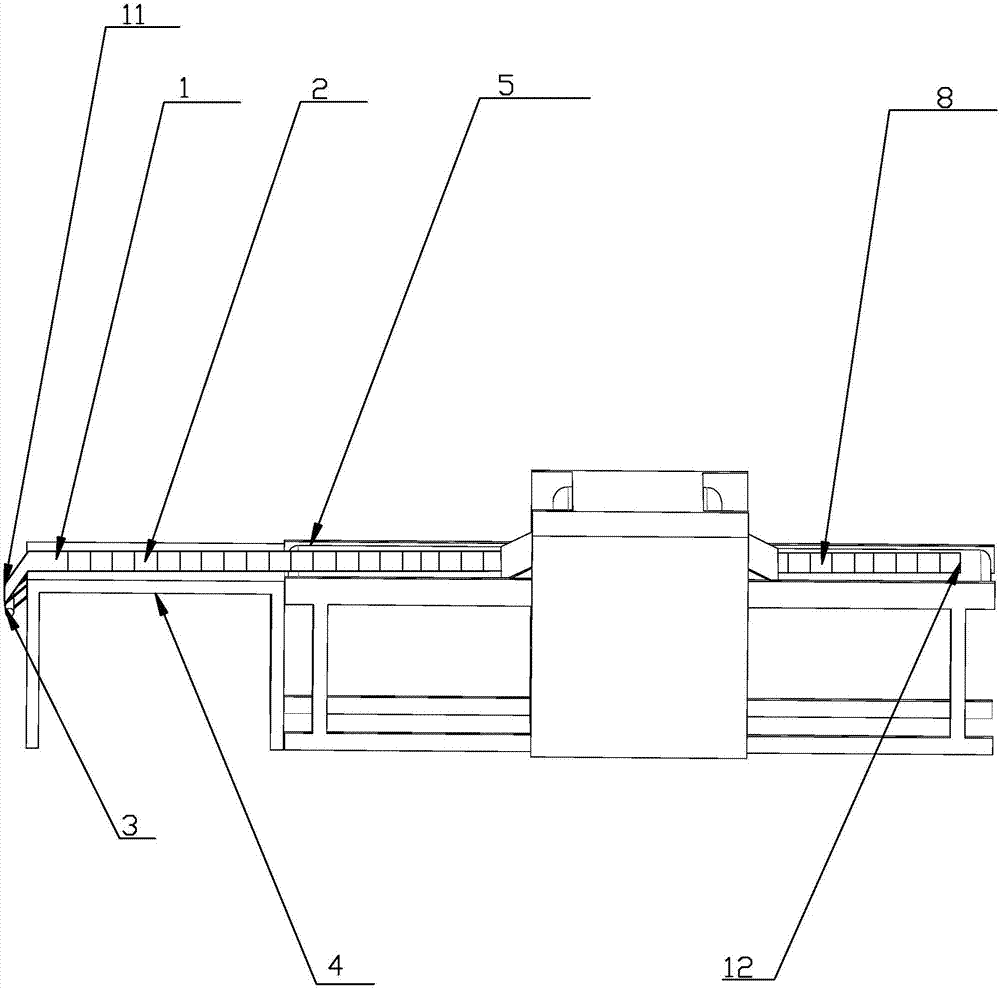

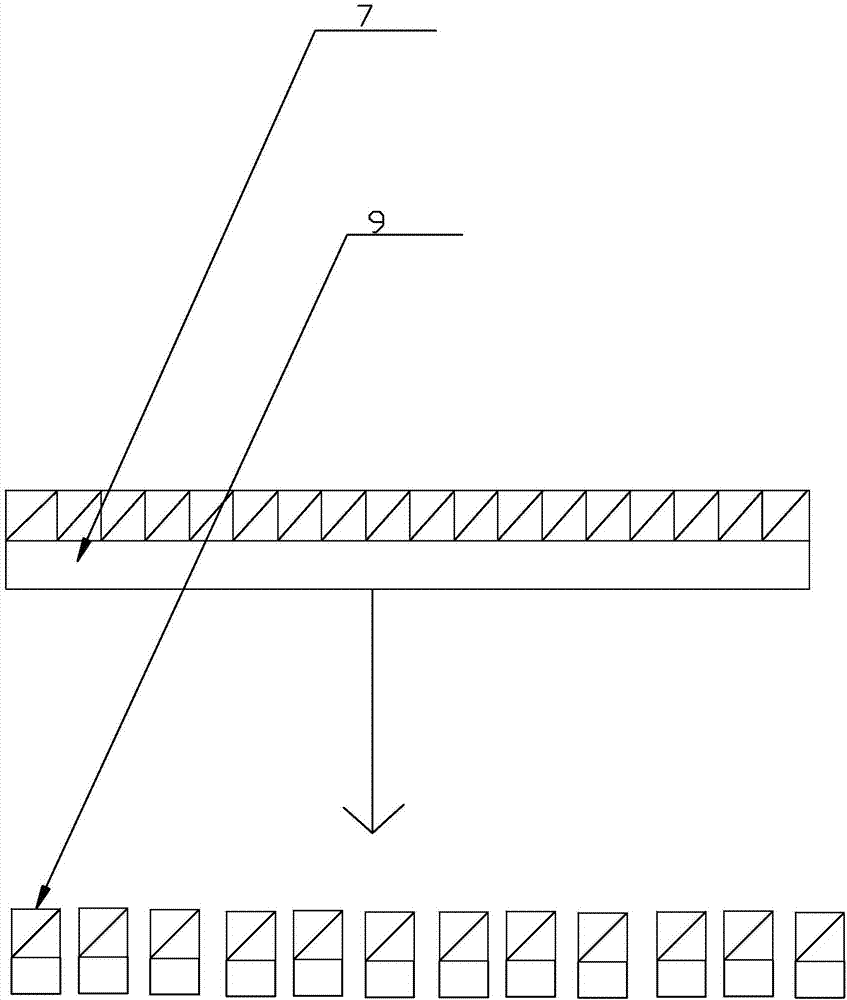

[0028] Such as Figure 1-Figure 5 As shown, the lining raw material of the present invention is a long inner lining that can be cut into several lining materials to be processed, and the cloth raw material is a long inner lining that can be cut into several required shapes of cloth to be processed. , the automatic lining bonding machine includes a frame 4, a conveyor belt 5 arranged on the frame, and a lining mechanism 6. In the first step, the long-shaped lining is manually cut into several required shapes of cloth to be processed 2. In the second step, the lining material positioning device 3 is set on the frame of the automatic lining machine, and in the third step, the top of the elongated cloth is arranged on the lining material positioning device 3, and the bottom end is arranged on the conveyor belt 4, and the conveyor belt 4 It can drive the elongated inner lining 1 to interact with each other. The fourth step is to stack several fabrics 2 to be processed on the elonga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com