Automatic leather tightening device

A leather, automatic technology, applied in the direction of leather stretching/stretching, etc., can solve the problems of difficult to guarantee the quality of the leather, single stretching direction, and low leather yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

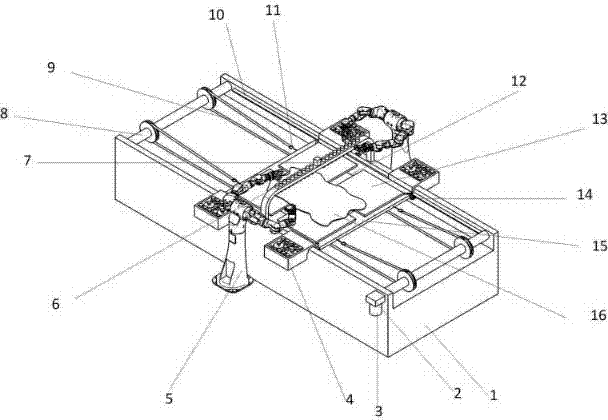

[0020] Below in conjunction with accompanying drawing, the present invention is described in further detail:

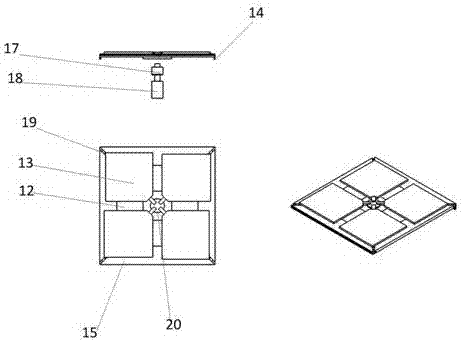

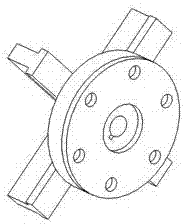

[0021] refer to figure 1 , an automatic stretching equipment, including a leather tensioning moving part, a leather edge position recognition component, a leather pressing component, a leather horizontal movement and positioning component. The PLC-based motion control component controls each component to move according to known laws; the leather horizontal movement and positioning component moves back and forth on the frame 1, and the working position is determined through a photoelectric switch; the leather tensioning moving part is driven by a stepping motor 17 drives the four-way centering motion mechanism 20 with self-locking performance to move the stretcher 13 back and forth, and the stepper motor 17 is installed on the piston rod of the cylinder 18; the leather edge position recognition component uses an industrial CCD camera 7 to take pictures of the leather a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com