A Method for Evaluating Tensile Capacity of Sleeve Joints Considering Grouting Compactness

A sleeve joint and bearing capacity technology, applied in the direction of instruments, geometric CAD, calculation, etc., can solve the problem of huge influence on the overall mechanical properties, and achieve the effect of preventing catastrophic consequences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

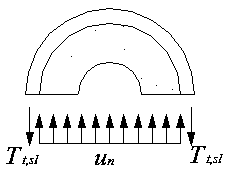

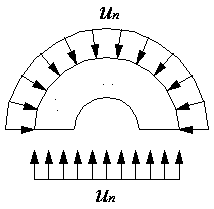

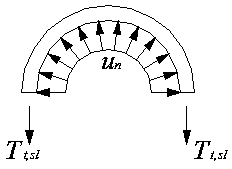

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0047] This embodiment provides a method for evaluating the tensile bearing capacity of sleeve joints considering grouting compactness, which is a grouting sleeve ( A method for evaluating and calculating the tensile capacity of steel bars).

[0048] First, the key parameters A and B are given according to the test, and then the actual steel-grouting bond force P is calculated through the proposed steel-grouting material bond force slip model b , and calculate the tensile bearing capacity T of the joint steel bar according to the tensile bearing capacity calculation formula b , and finally by comparing the reinforcement-grouting material bonding force P b and the tensile capacity T of the joint reinforcement b Give the tensile bearing capacity P of the sleeve joint u .

[0049] Specifically, wherein, the tensile bearing capacity T of the joint stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com