Optical path sealing mechanism with environment monitoring and light beam quality detection interface

A detection interface and environmental monitoring technology, applied in the direction of measuring devices, measuring device shells, instruments, etc., can solve the problems of lens pollution and damage, cumbersome operation process, light guide optical path can not monitor the environmental status of optical path channel in real time, etc., to achieve low cost, achieve simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

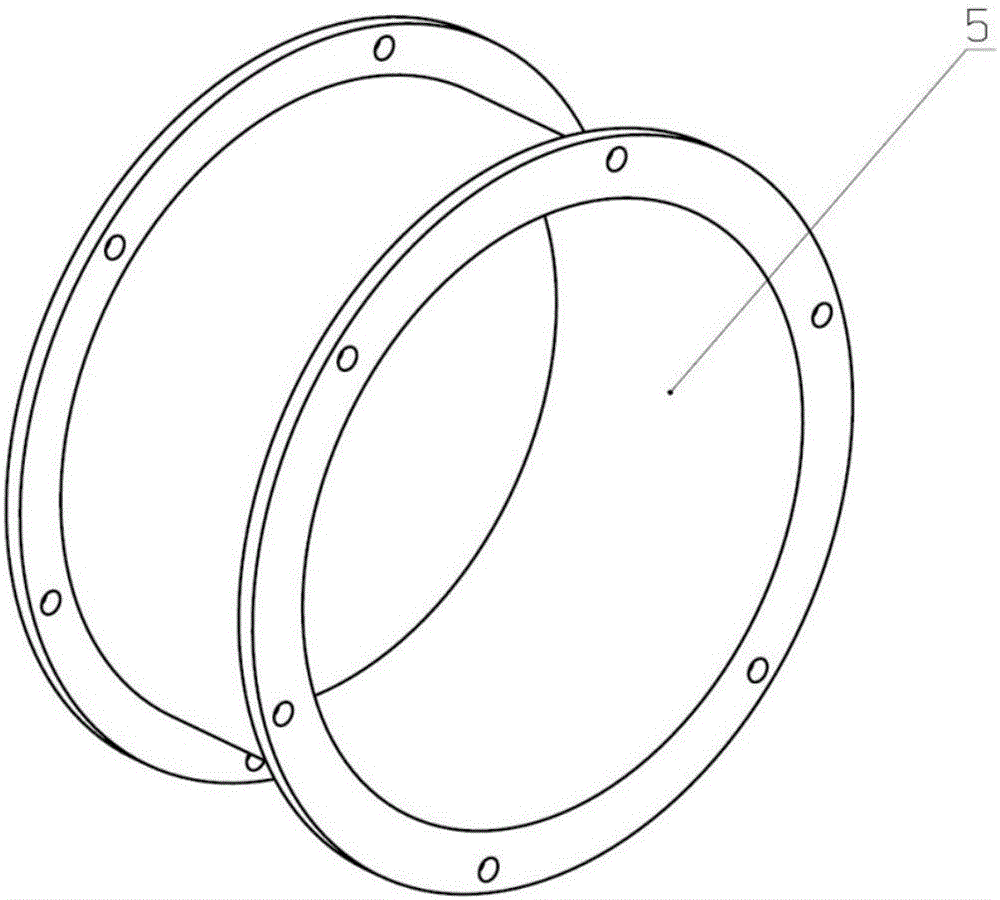

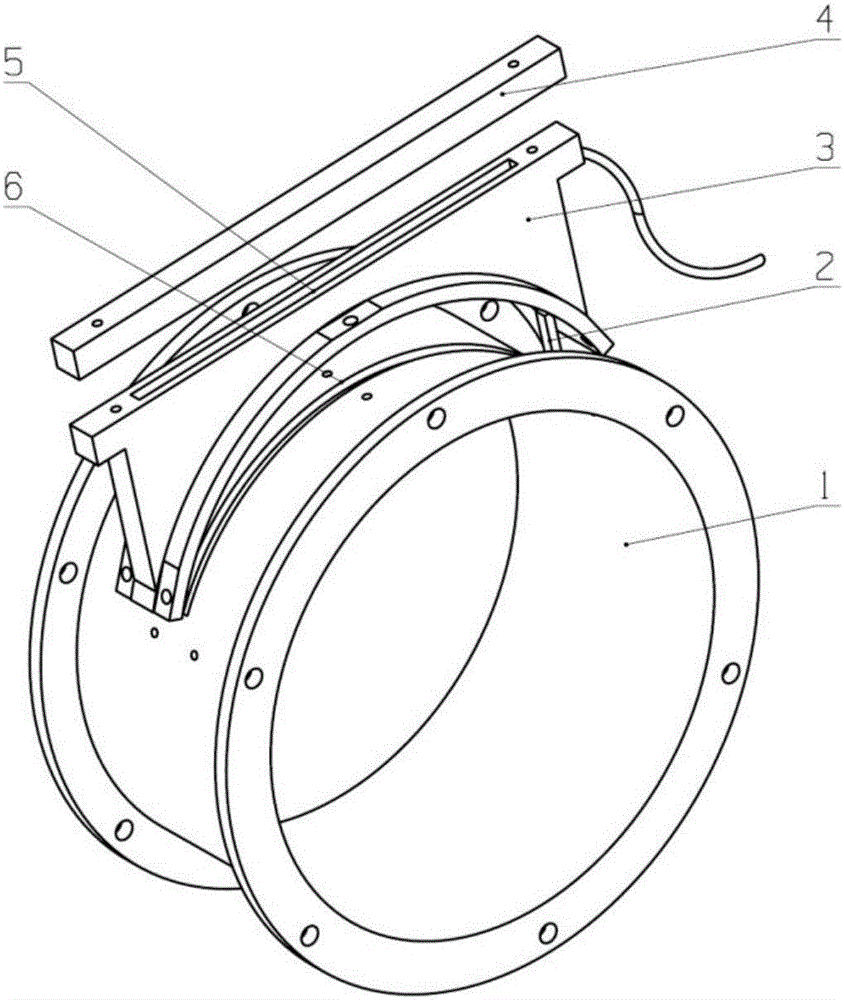

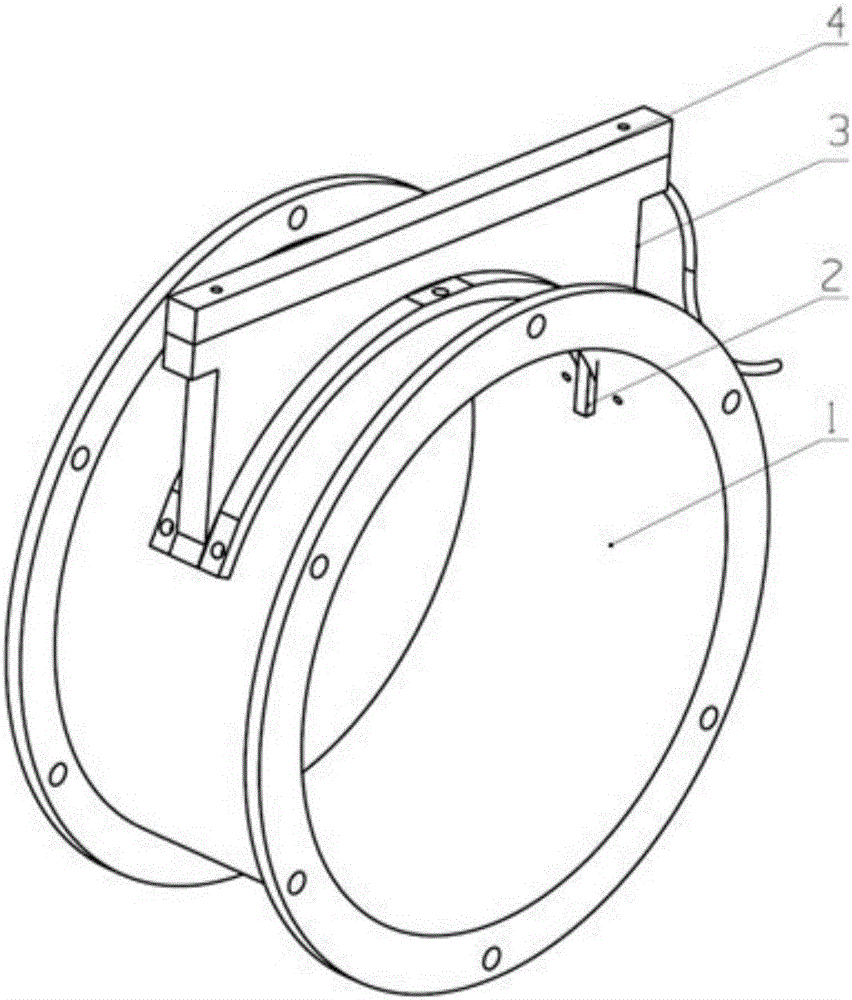

[0011] Specific implementation mode 1. Combination figure 2 and image 3 In this embodiment, the optical path sealing mechanism with the interface for environmental monitoring and beam quality detection includes a sealing channel 1 with a detection interface, a sealing slot detection board, and a sealing cover 4 for the slot detection board. Channel 1 is to change the original optical path sealed channel into a sealed channel with a detection interface; that is, a detection interface 6 is reserved on the sealed channel 1 with a detection interface; the sealing slot detection is fixed on the detection interface 6 plate; the slot detection board sealing cover 4 seals and protects the sealing slot detection board. The sealing slot detection board includes a sealing slot plate 3 and an environmental monitoring sensor 2, the sealing slot plate 3 has a slot hole 5, and the slot hole 5 and the detection interface 6 are positioned and connected by screw sealing, which can Quickly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com