A cooling system and vehicle

A cooling system and vehicle body technology, applied in engine cooling, machines/engines, mechanical equipment, etc., can solve problems such as reduced wind pressure, reduced heat dissipation efficiency, and reduced air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, steps, structure, The features and their effects are detailed.

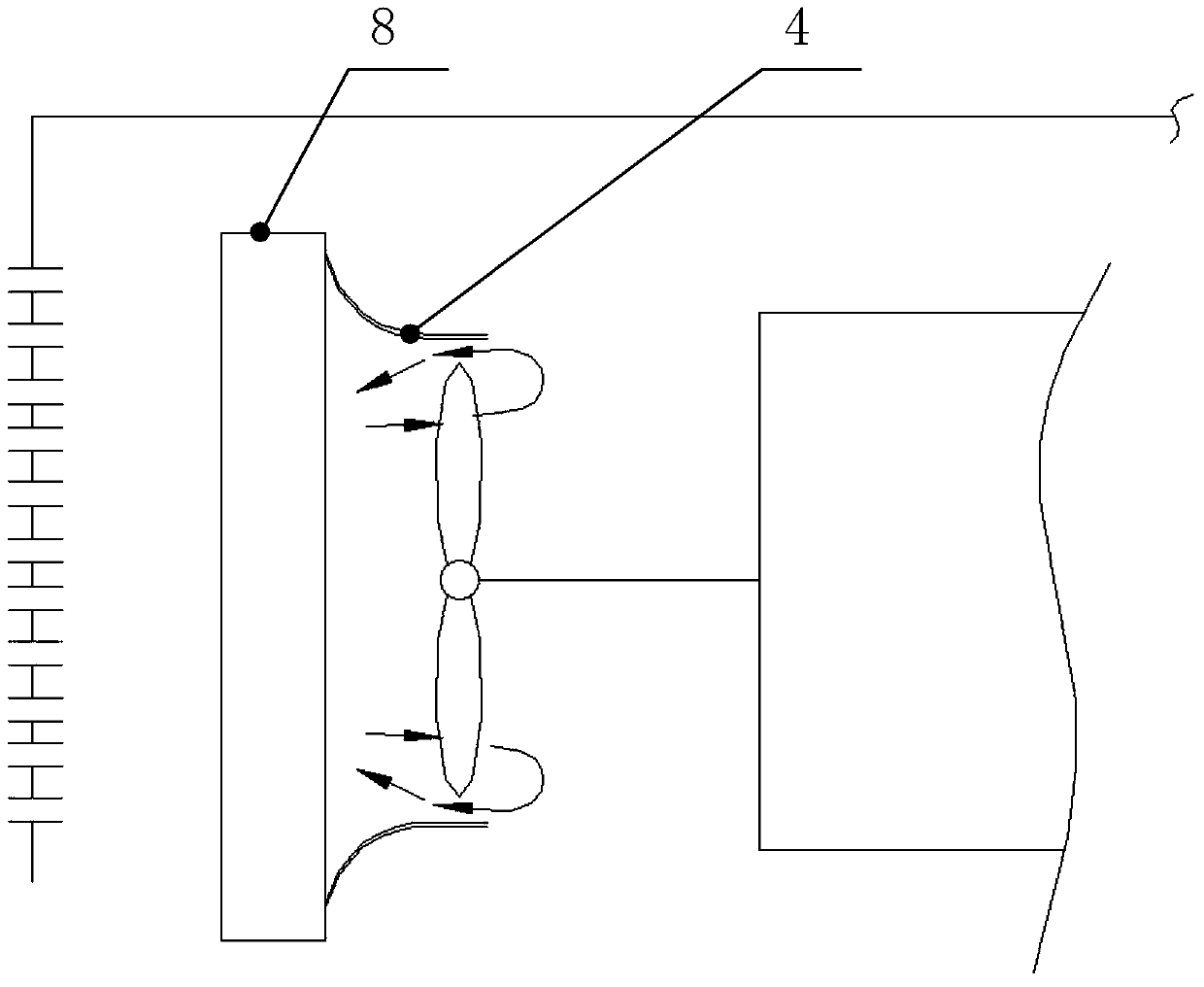

[0022] see figure 1 As shown, it is a schematic diagram of hot air backflow and wind pressure loss caused by the gap between the fan and the air guide cover in the prior art, wherein the radial gap between the fan 4 and the air guide cover 8 causes local eddy currents in the air field (as shown by the arrows) ), resulting in hot air backflow and wind pressure loss, greatly reducing air flow and affecting heat dissipation performance.

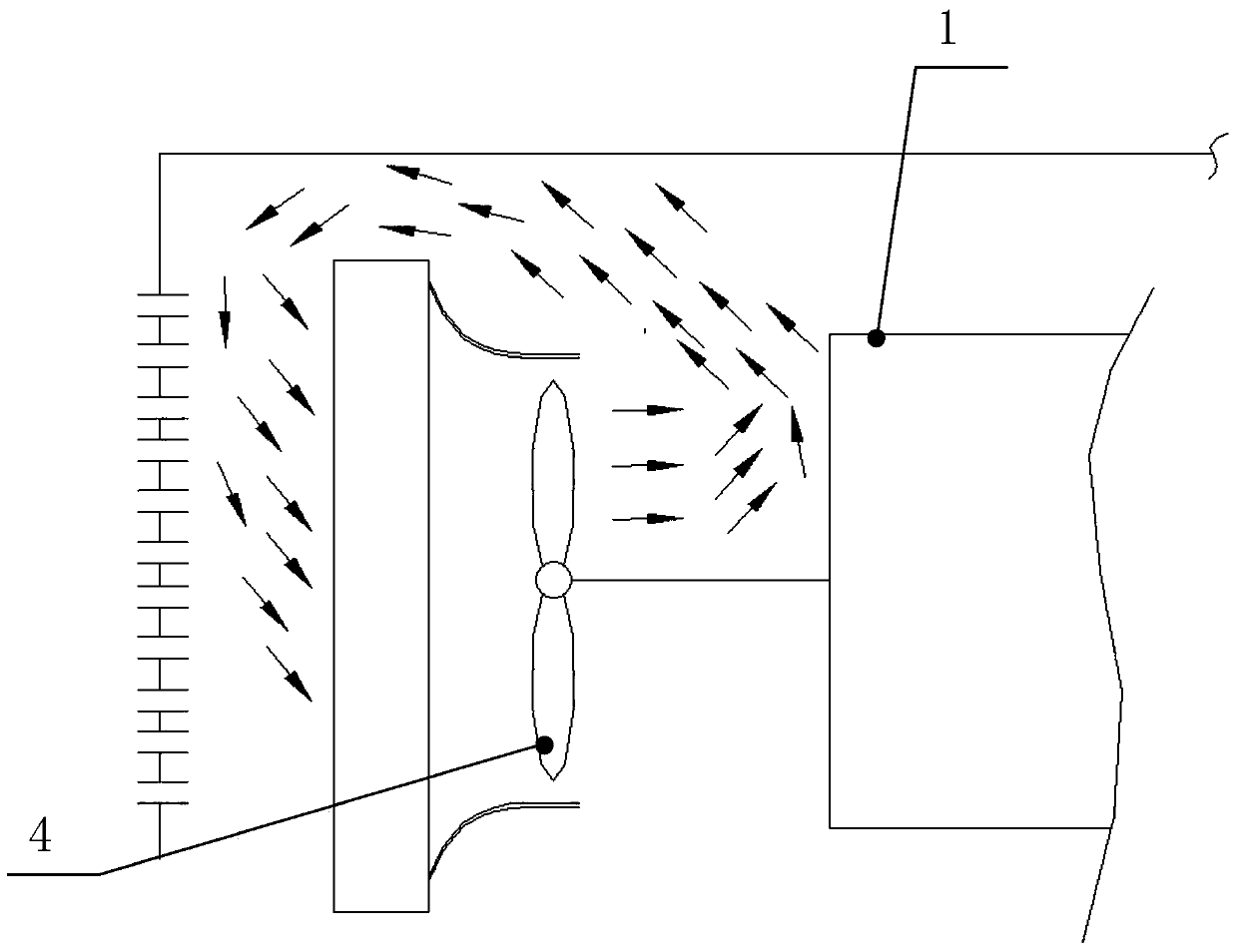

[0023] In addition, the current cooling system of automobiles basically does not have a guiding design for the heat dissipation air flow field, resulting in the occurrence of wind pressure loss and hot air backflow everywhere, which seriously affect the heat dissipation performance.

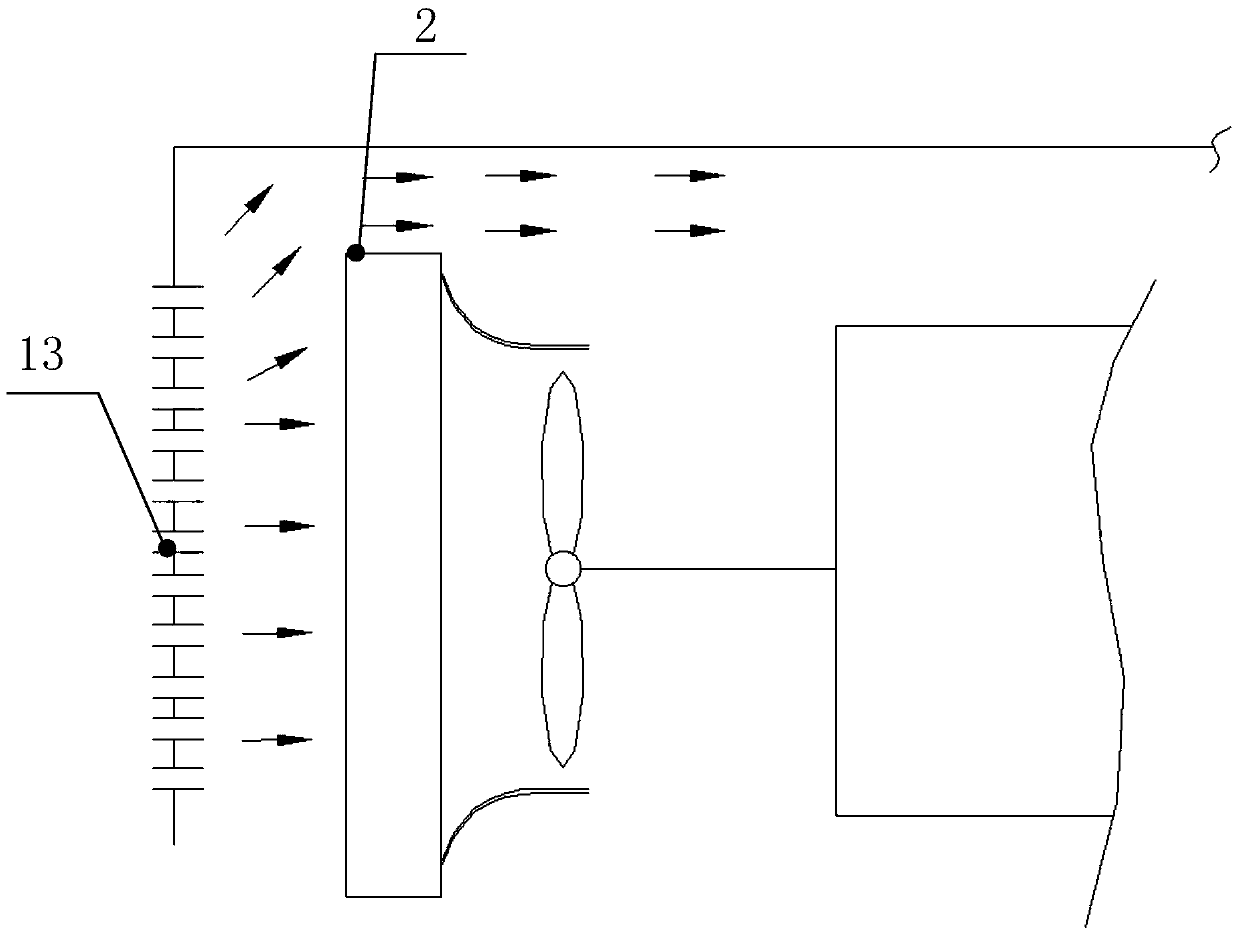

[0024] see figure 2 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com