Quick automatic installation tool for charged fire welding operation

A technology of automatic installation and tools, applied in the direction of overhead line/cable equipment, etc., can solve the problems of time-consuming and laborious, complicated clamping process, etc., and achieve the effect of simple operation process, good connection effect and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

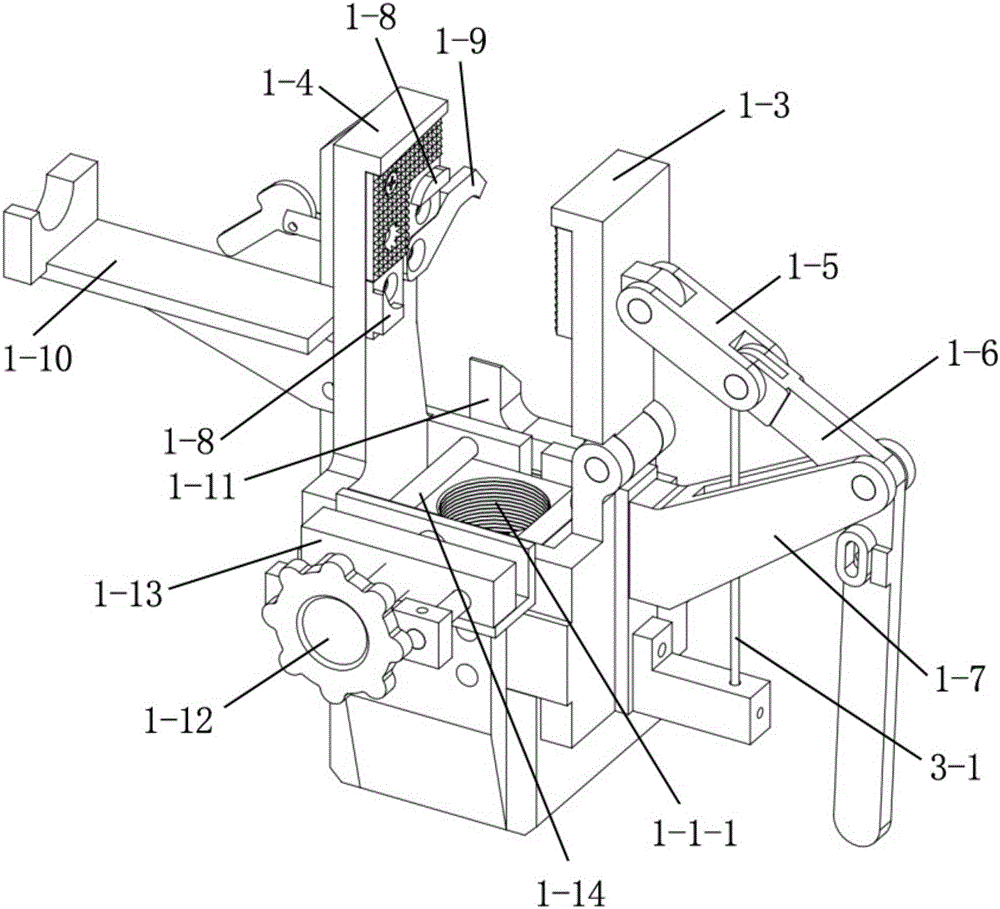

[0034] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0035] A quick and automatic installation tool for live fire connection operation, used for installation of J-shaped parallel groove clamp 100, said J-shaped parallel groove clamp 100 includes two clamp bodies 101, and the two clamp bodies 101 pass through the fastening assembly Fastening connection, the fastening components are bolts 102 and matching nuts 103 .

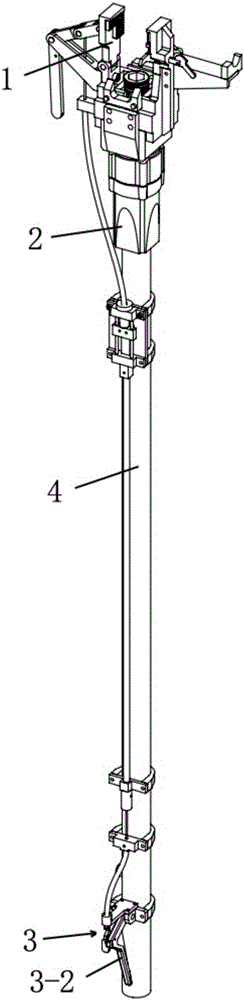

[0036] Such as figure 1 Shown, the present invention is used for the fast automatic installation tool of electrified fire contacting operation to comprise

[0037] Clamping device 1: used to clamp the J-shaped parallel groove clamp 100;

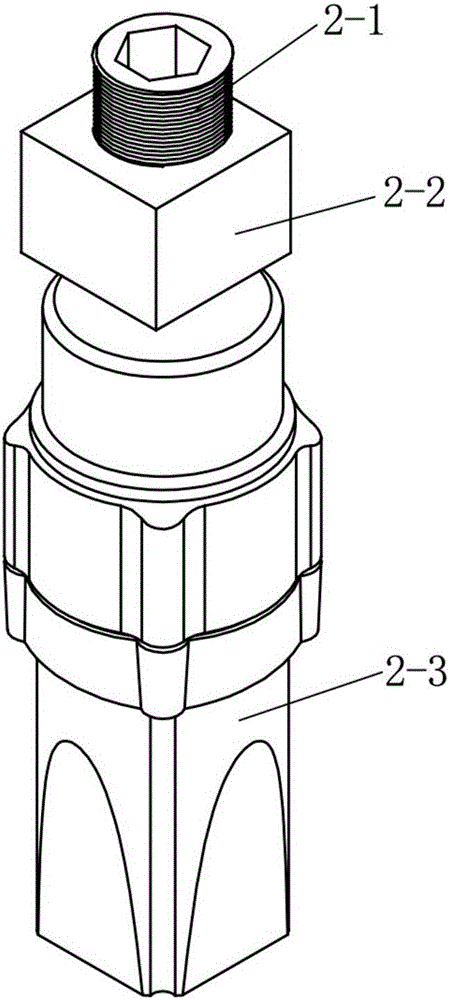

[0038] Tightening device 2: used to tighten the nut 103 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com