Power equipment knob

A technology for electrical equipment and knobs, applied in circuits, electrical switches, electrical components, etc., can solve the problems of easy wear and tear, inconvenient inspection and maintenance, and easy wrong rotation operation, to prevent wrong rotation operation, not easy to wear and fail, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

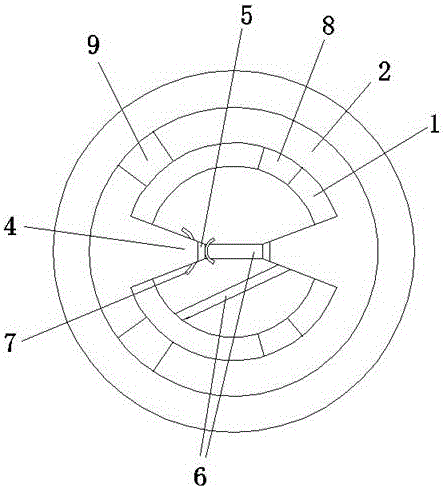

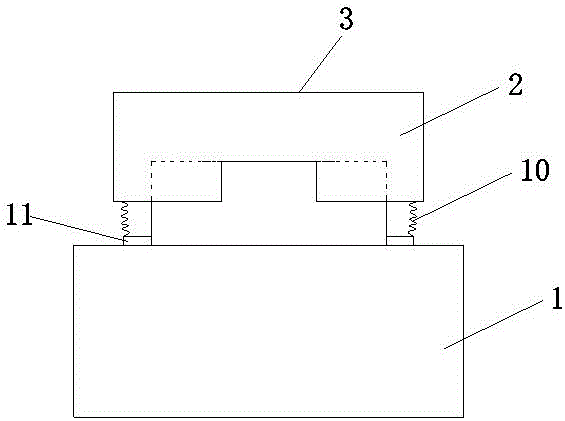

[0026] A power device knob such as figure 1 and figure 2 As shown, it includes a cylindrical inner ring tube 1, and the longitudinal section of the inner ring tube 1 is set in a "convex" shape. The top is provided with a closed circular plate 3;

[0027] The lower surface of the closed circular plate 3 is connected with two sliders 4 with a trapezoidal transverse section, the two sliders 4 are evenly and symmetrically distributed, and the ends of the sliders 4 are respectively connected with insulating sheets 5 extending downward;

[0028] The lower part of the inner ring cylinder 1 is provided with wire holes, and the loops of the wires 6 extend into the inner ring cylinder 1 through the wire holes respectively. The ends of the wires 6 are respectively connected with a conductive sheet 7, and the two conductive sheets 7 are in contact with each other. When the outer cover ring tube 2 rotates outside the inner ring tube 1, the slider 4 is driven to move, so as to drive the ...

Embodiment 2

[0033] A knob for electric equipment is similar to Embodiment 1, the difference is that the closed circular plate 3 and the outer cover ring cylinder 2 are arranged in an integrated structure.

[0034] Preferably, the insulating sheet 5 is arranged in the shape of a rectangular strip.

[0035] Preferably, the wire hole is set as a circular hole.

[0036] Preferably, the number of wire holes is four.

[0037] Preferably, an annular protective ring is provided at the edge of the wire hole.

[0038] Preferably, the number of the inner notch 8 and the outer notch 9 is two respectively.

[0039] Preferably, the inner notches 8 are evenly and symmetrically distributed on the upper side wall of the inner ring tube 1 , and the outer notches 9 are evenly and symmetrically distributed on the side wall of the outer cover ring tube 2 .

[0040] Preferably, both the inner notch 8 and the outer notch 9 are set in a rectangle.

[0041] Preferably, the conductive sheet 7 is configured as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com