Integrated slurry mixing, leveling and screeding device with suspension rails

An integrated, suspended rail technology, applied in the direction of erecting/assembling bridges, bridge parts, bridges, etc., can solve the problems of flatness and waterproof performance, poor concrete integrity, and difficulty in ensuring flatness, etc., to improve construction quality and guarantee Stiffness, the effect of avoiding secondary seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

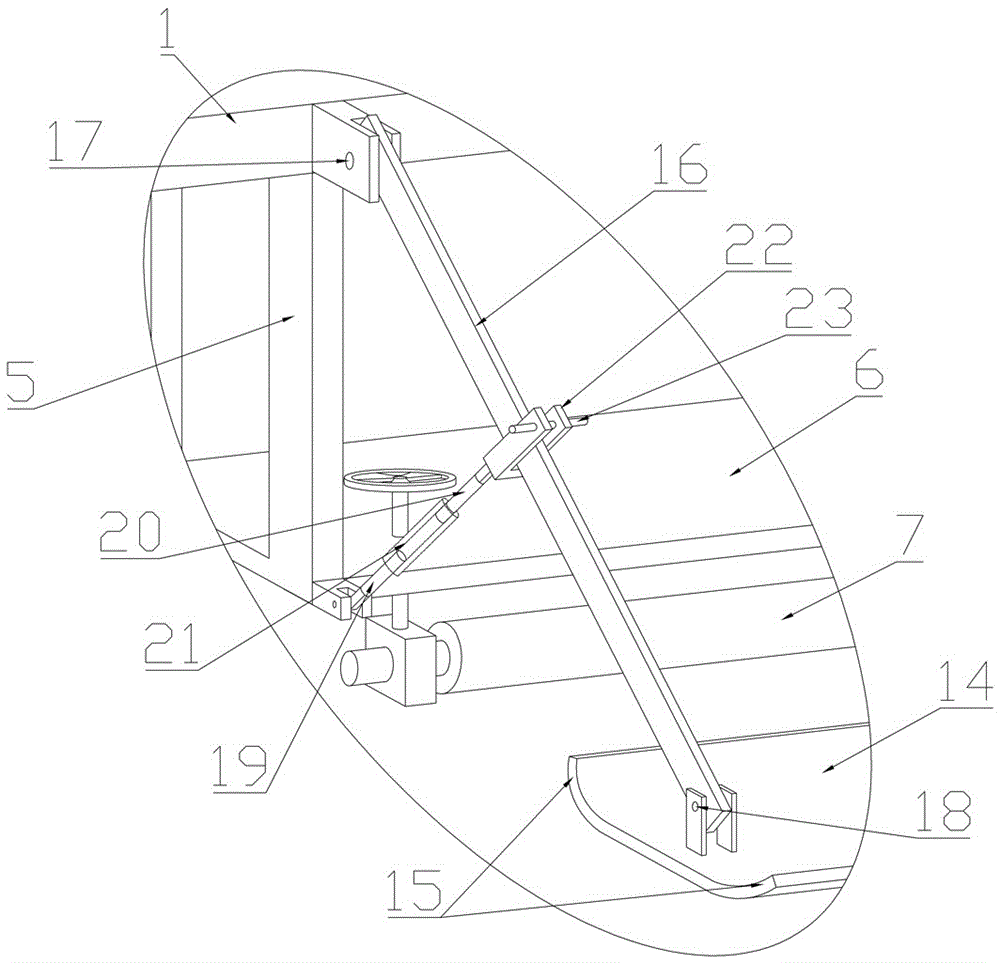

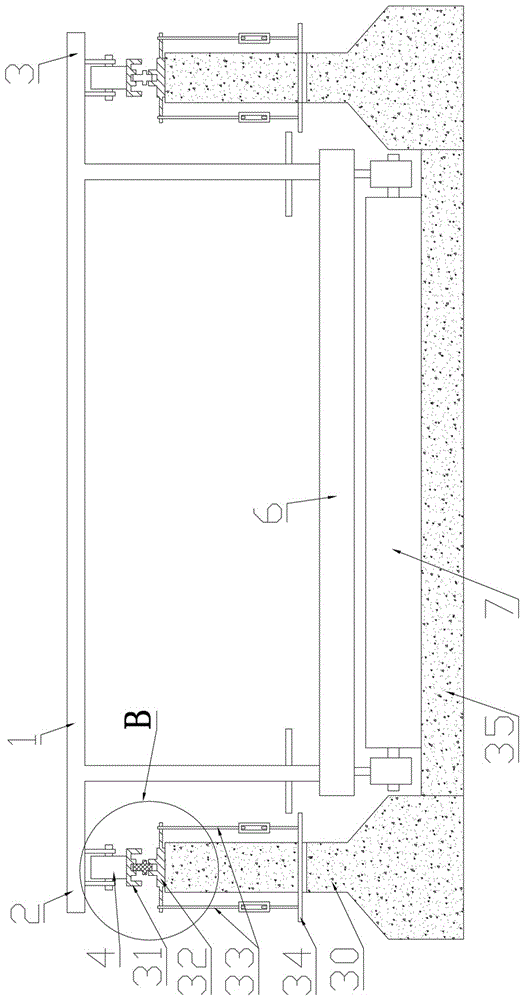

[0025] Embodiment 1: A kind of hanging rail integrated pulp leveling and smoothing device, see Figure 1 to Figure 5 It includes two parallel tracks 31 for laying on the anti-collision barriers 30 on both sides of the bridge plate 35, a suspension mechanism that is arranged on the two tracks 31 and can slide on the track 31, and also includes a suspension mechanism that is arranged on the suspension mechanism. The bottom plate 6 connected to the suspension mechanism through the connecting piece 5, the roller shafts 7 and 8 for pulping and leveling arranged under the bottom plate 6, and the troweling plate 14 for smoothing the concrete of the leveling layer , the troweling plate 14 is hinged to the suspension mechanism through the connecting rod 16, and the connection between the connecting rod 16 and the troweling plate 14 is also hinged.

[0026] Specifically, the suspension mechanism described in this embodiment includes a suspension part 1, the bottom plate 6 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com