Telescopic arm barrel and crane boom

A telescopic boom and boom technology, which is applied in the field of lifting equipment, can solve the problems of complicated boom disassembly process and low maintenance efficiency, and achieve the effects of shortening the time required for disassembly, reducing disassembly steps and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

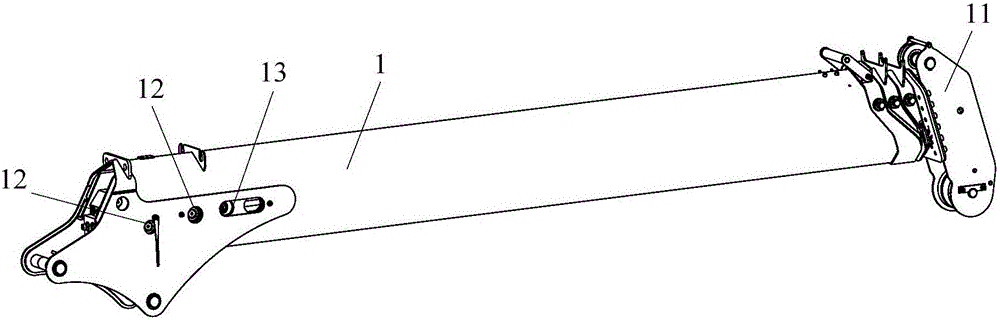

[0043] Such as figure 1 As shown, the telescopic arm tube 1 provided by the embodiment of the present invention includes: a plurality of joint arms that are telescopically sleeved sequentially from the outside to the inside, wherein one or more joint arms are provided with telescopic device installation for installing the telescopic device. Hole, on each section arm sleeved on the outer side of the section arm provided with the installation hole of the expansion device, there is correspondingly provided with the through hole 12 of the expansion device. The through holes 12 are aligned with each other.

[0044] When the telescopic boom tube 1 of the embodiment of the present invention is applied to the boom, the installation process of the boom is as follows: connect each section arm in turn, so that each section arm is sequentially fitted; then place the telescopic device in the innermost section arm , and connect the telescoping device with the joints to be connected when ea...

Embodiment 2

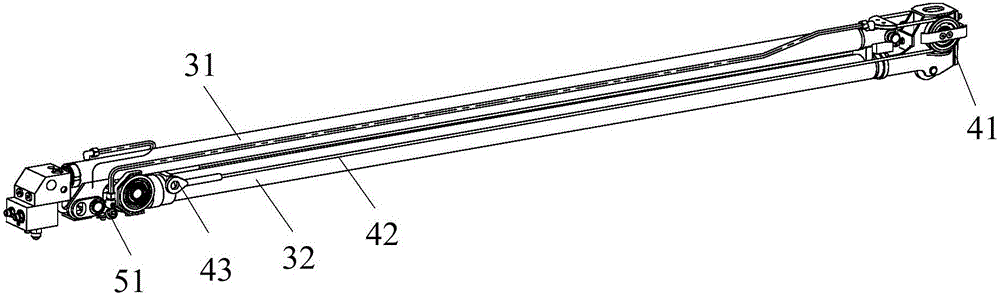

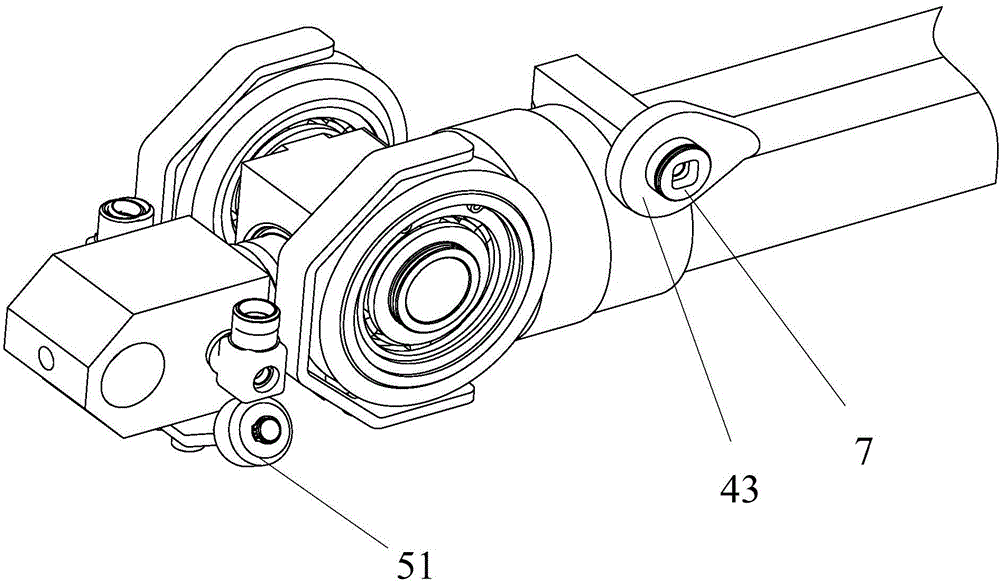

[0050] Such as Figure 1-11 As shown, the second embodiment of the present invention provides a lifting arm, which includes the telescopic boom tube 1 provided in the first embodiment above, and a telescopic device is installed in the telescopic boom tube 1 . Specifically, the telescopic device can be sent to the inside of the telescopic arm tube 1 from the arm tail of the telescopic arm tube 1 or the arm head 11. When the telescopic device is sent into the telescopic arm tube 1 from the arm tail of the telescopic arm tube 1, The structure of the telescopic arm barrel 1 does not need to be changed; when the telescopic device is sent into the interior of the telescopic arm barrel 1 from the arm head 11 of the telescopic arm barrel 1, the arm head 11 of the telescopic arm barrel 1 needs to be designed as a detachable structure, namely The cylinder body of the telescopic arm cylinder 1 is directly and detachably connected to the arm head 11 , for example, the cylinder body of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com