Aqueous polymer-silicon oil hybrid composition

一种组合物、聚合物的技术,应用在油墨、涂层、家里用具等方向,能够解决有效性低、昂贵等问题,达到良好应用性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0173] A particularly preferred embodiment of the method of the invention comprises the following steps:

[0174] i. dissolving the non-polymerizable silicone oil in the ethylenically unsaturated monomer M;

[0175] ii. emulsifying the solution of non-polymerizable silicone oil obtained in step i. in water containing at least one surfactant, whereby a conventional oil-in-water emulsion (coarse emulsion) is obtained;

[0176] iii. The droplet size of the conventional oil-in-water emulsion of step ii. is crushed to obtain an oil-in-water aqueous microemulsion having an average droplet size as determined by dynamic light scattering of less than 1000 nm, especially 20-500 nm, especially 50-400 nm , that is, aqueous O / W emulsion;

[0177] iv. Initiating free radical polymerization in the aqueous oil-in-water microemulsion of step iii.

[0178] Steps i. and ii. can be carried out as consecutive steps or as a single step. That is, the non-polymerizable silicone oil and the ethylen...

Embodiment 1

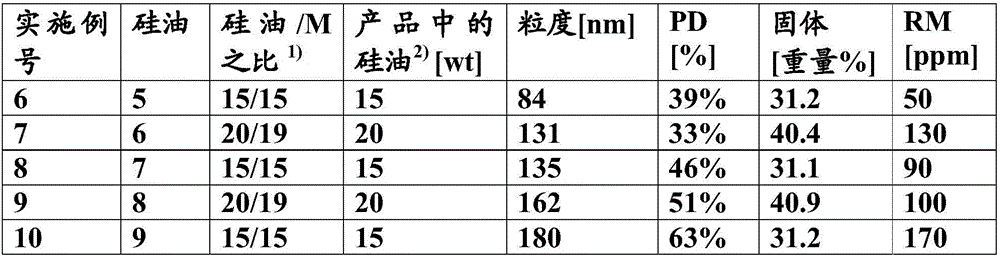

[0258] 81.6g Silicone Oil 2 (100% active polysiloxane) was dissolved in 68.4g MMA, 6.08g SMA, 1.52g MAA and 0.23g BDDA. The oil phase was added dropwise to a stirred solution of 20.1 g of Surfactant 1 in 202 g of deionized water. The mixture was stirred for 30 minutes and treated by ultrasound at 60% power for 20 minutes per 500 g of emulsion using a Bandelin Sonoplus, Generator GM 2200, 200 W, 20 kHz. A kinetically stable microemulsion was obtained with an average droplet size of 147 nm.

[0259] 3.8 g of a 10% by weight aqueous solution of tert-butyl hydroperoxide were added to the microemulsion. The microemulsion was heated to 40°C. 15.8 g of a 4.8% by weight Rongalit C aqueous solution were added to the reactor within 1 hour at 40°C. The reaction mixture was continuously stirred by a mechanical stirrer and maintained at 60°C for 1 hour, then cooled to 22°C. The pH of the resulting polymer dispersion was then adjusted to 8.6 by adding 0.87 g of AMP and the dispersion wa...

Embodiment 2

[0261] 81.6g Silicone Oil 3 (100% active polysiloxane) was dissolved in 68.4g MMA, 6.08g SMA, 1.52g MAA and 0.23g BDDA. The oil phase was added dropwise to a stirred solution of 20.1 g of Surfactant 1 in 202 g of deionized water. The mixture was stirred for 30 minutes and treated by ultrasound at 60% power for 20 minutes per 500 g of emulsion using a Bandelin Sonoplus, Generator GM 2200, 200 W, 20 kHz. A kinetically stable microemulsion was obtained with an average droplet size of 154 nm.

[0262] 3.8 g of a 10% by weight aqueous solution of tert-butyl hydroperoxide were added to the microemulsion. The microemulsion was heated to 40°C. 15.8 g of a 4.8% by weight Rongalit C aqueous solution were added to the reactor within 1 hour at 40°C. The reaction mixture was continuously stirred by a mechanical stirrer and maintained at 60°C for 1 hour, then cooled to 22°C. The pH of the resulting polymer dispersion was then adjusted to 8.7 by adding 0.48 g of AMP and the dispersion wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

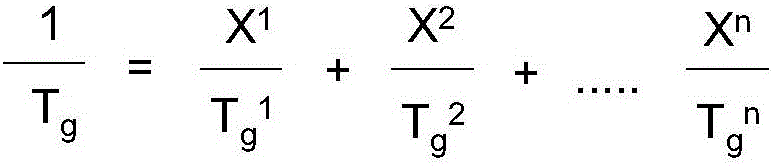

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com