A flip-type dust-proof tire breaker

A tire breaker and flap-type technology, applied in the directions of roads, buildings, traffic restrictions, etc., can solve the problems of inability to lift, high working environment requirements, poor crash resistance of tire breakers, etc., to achieve cost reduction, flexible use environment, Enhanced crashworthiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but this should not be used as a limitation to the protection scope of the claims of the present application.

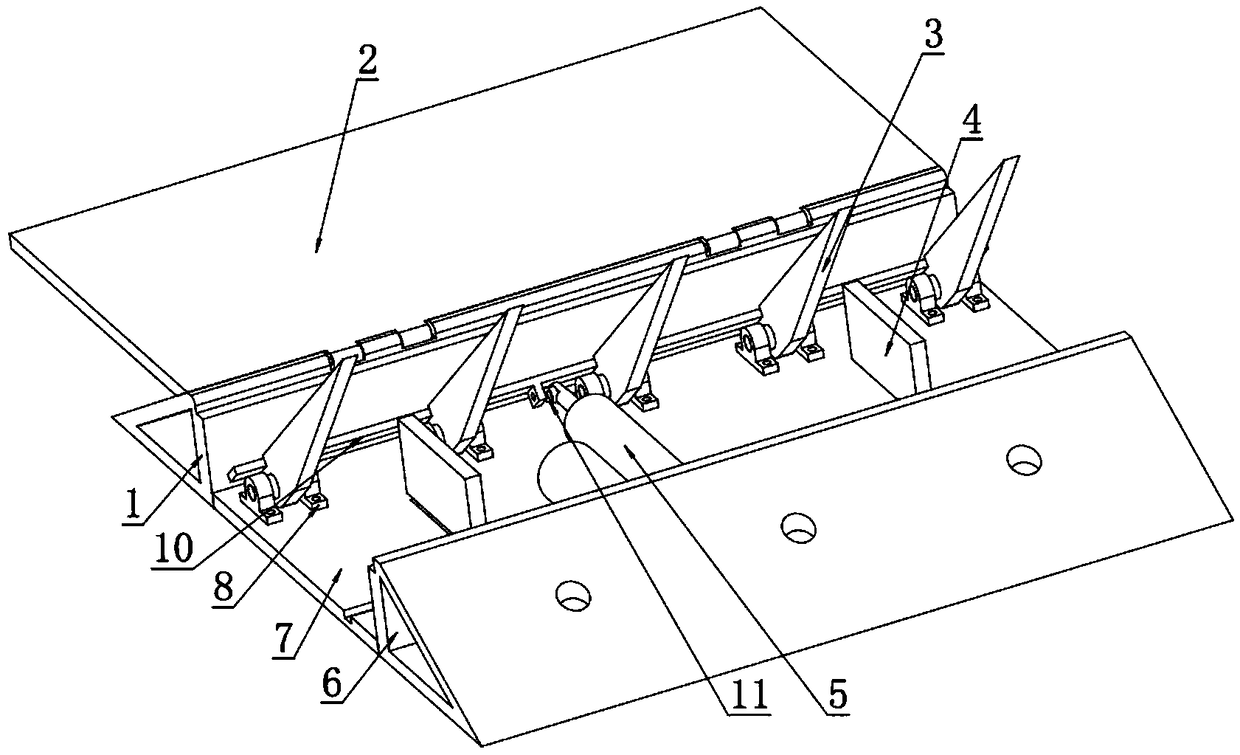

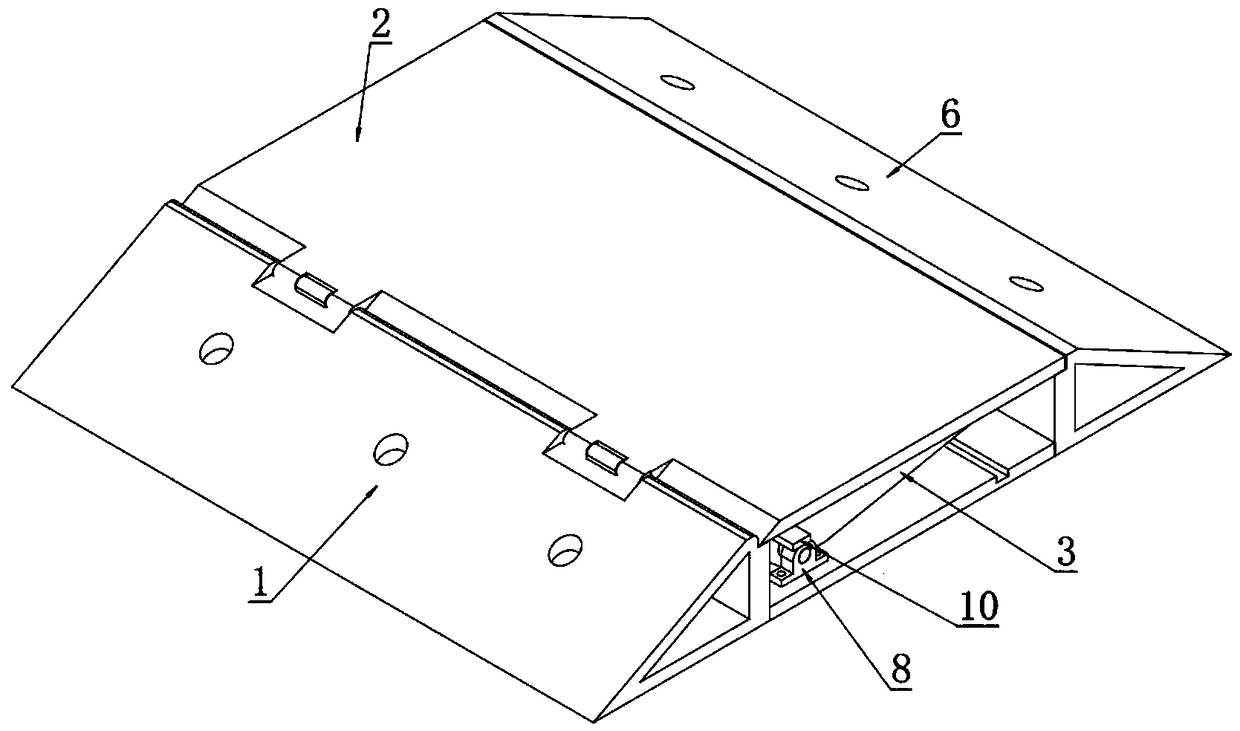

[0020] The flap type dust-proof tire breaker of the present invention (abbreviation tire breaker, see Figure 1-6 ) includes connecting triangular hollow block 1, horizontal plate 2, spur 3, reinforcing rib plate 4, electric push rod 5, supporting triangular hollow block 6, bottom plate 7, shaft seat 8, force relief base 9, horizontal plate 10 and connecting plate 11; The lower part connecting the triangular hollow block 1 and supporting the triangular hollow block 6 is symmetrically fixed on both sides of the bottom plate 7, the upper part connecting the triangular hollow block 1 and supporting the triangular hollow block 6 is connected to the horizontal plate 2, and the spur 3 is installed through the shaft seat 8 On base plate 7,

[0021] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com