Method for detecting orifice of conical bore

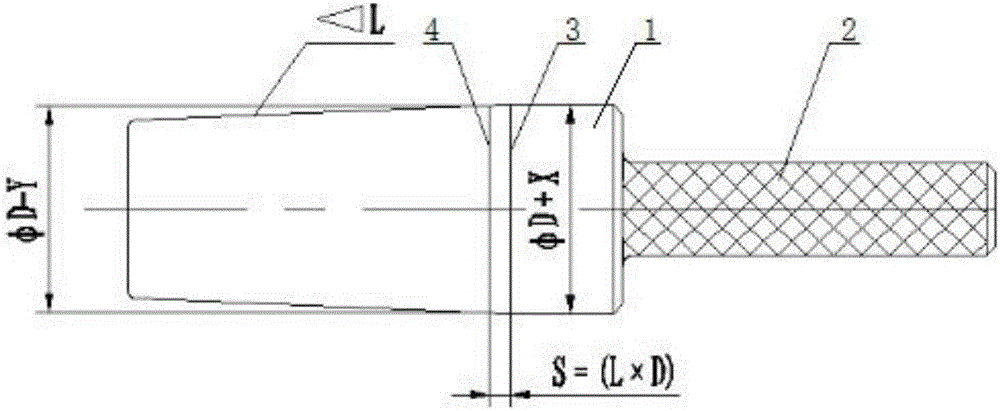

A detection method and a tapered hole technology, applied in the field of mechanical processing, can solve the problems of high manpower and time consumption, low efficiency, high cost, etc., and achieve the effect of low cost, convenient operation and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

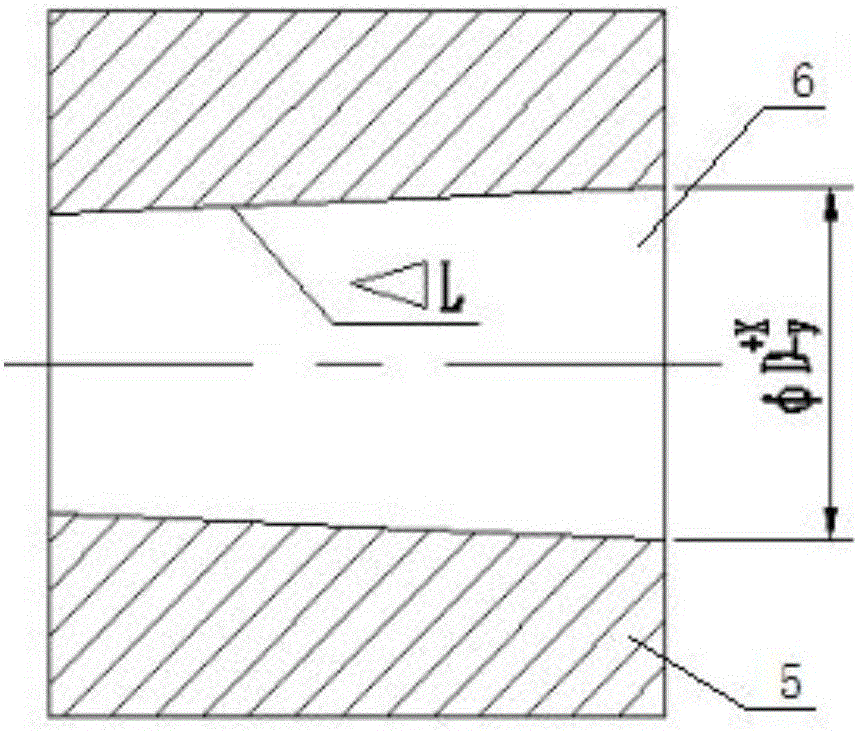

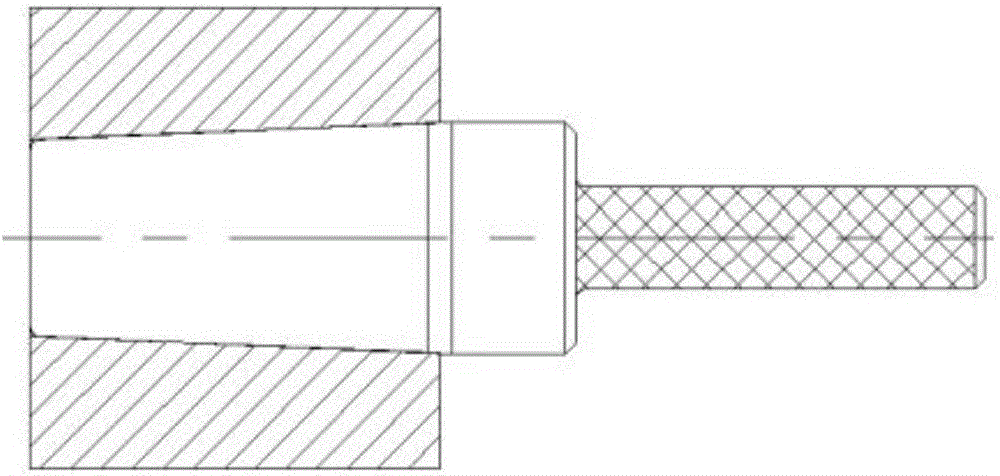

[0024] Embodiment 1: Insert the vertebral body 1 into the conical hole 6 on the part to be measured 5, the right end surface of the part to be measured 5 is located between the upper deviation line 3 and the lower deviation line 4, as image 3 As shown, the size of the tapered hole 6 on the part 5 to be tested is qualified.

Embodiment 2

[0025] Embodiment 2: insert the vertebral body 1 into the conical hole 6 on the part to be measured 5, and the right end surface of the part to be measured 5 is located outside the upper deviation line 3 and the lower deviation line 4, as Figure 4 As shown, the size of the tapered hole 6 on the part 5 to be tested is smaller than the standard, which is unqualified.

Embodiment 3

[0026] Embodiment 3: Insert the vertebral body 1 into the conical hole 6 on the part to be measured 5, and the right end surface of the part to be measured 5 is located outside the upper deviation line 3 and the lower deviation line 4, as Figure 5 As shown, the size of the tapered hole 6 on the part to be tested 5 is larger than the standard, which is unqualified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com