A heat shield welding tool

A technology of welding tooling and heat shield, which is applied in the field of mechanical processing, can solve the problems of scrapped parts and low product qualification rate, and achieve the effects of improving production efficiency, improving weld quality, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

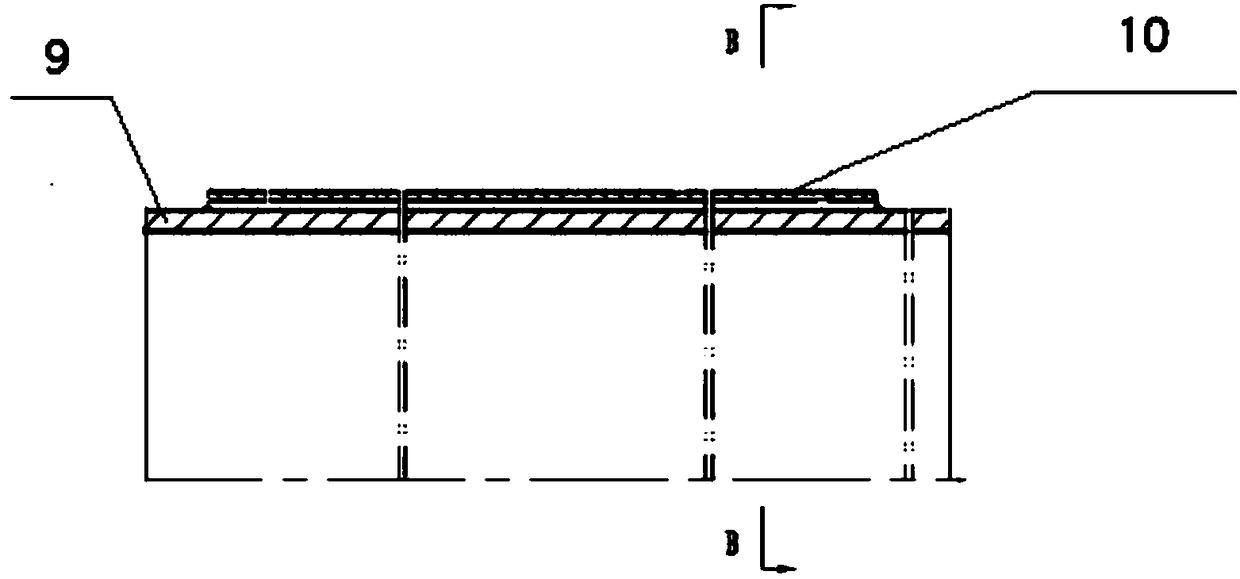

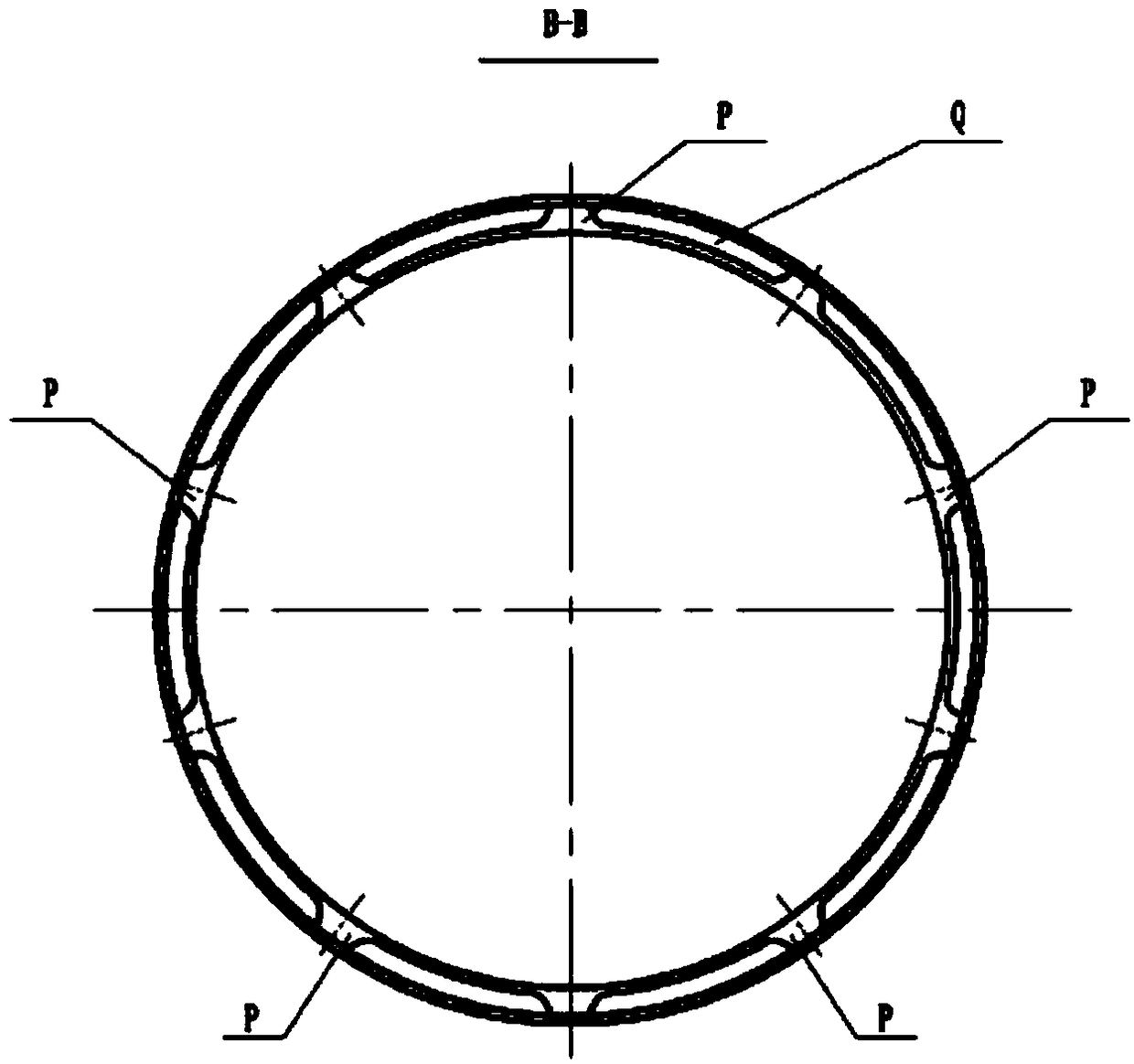

[0016] Such as figure 1 and 2 As shown, the heat shield assembly is connected by the inner heat insulation cylinder 9 and the outer heat insulation cylinder 10 by vacuum electron beam welding, and the uniform distribution between the inner heat insulation cylinder 9 and the outer heat insulation cylinder 10 is required Five ribs are welded, the joint form is lap joint, the weld is at the center of the rib, and the offset center is not more than 1mm. figure 2 P in represents the uniform distribution of 10 ribs, and Q is the cavity between the ribs; figure 2 There are 10 ribs drawn in the figure. When welding, only 5 ribs need to be welded evenly; in order to achieve the purpose of reducing scribing and improving efficiency, the following scheme is adopted:

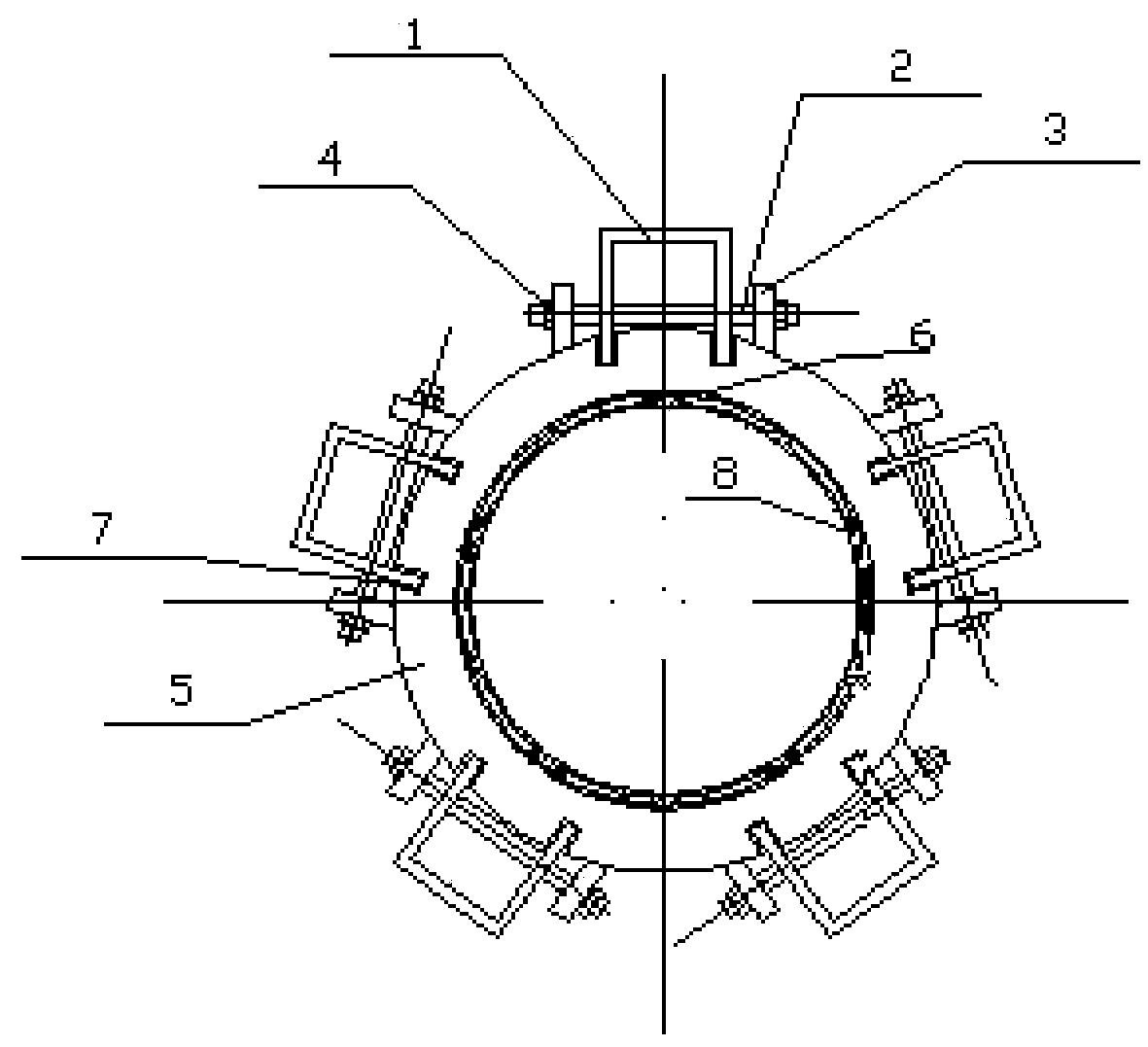

[0017] A fixture is now designed, a heat shield welding tool, including a circular fixture body 5, and lead frames 1 are evenly distributed on the outside of the fixture body 5 in the circumferential direction, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com