Metal sheet embossing rough rectification device

A metal sheet, embossing technology, applied in the field of metal sheet rough straightening device, can solve the problems of affecting the use of the sheet, not easy to clamp, and straightening the entire plate surface, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

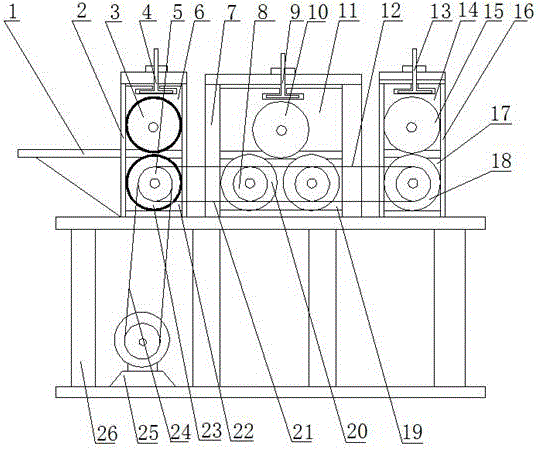

[0018] Embodiment 1: As shown in Figure 1, a metal sheet embossing rough correction device, including a feeding frame 1, a nip-in roller installation frame 2, a nip-in upper roller 3, a nip-in roller adjustment device 4, and a nip-in roller transmission chain Wheel 5, biting upper roller mounting plate 6, rough straightening roller installation frame 7, rough straightening roller driving sprocket 8, rough straightening roller adjustment device 9, rough straightening upper roller 10, rough straightening upper roller mounting plate 11, transmission chain 12 , Embossing roller adjustment device 13, embossing upper roller mounting plate 14, embossing upper roller 15, embossing roller mounting frame 16, embossing lower roller mounting plate 17, embossing lower roller 18, rough correction lower roller mounting plate 19 , rough straightening lower roller 20, chain two 21, bite into the lower roller mounting plate 22, bite into the lower roller 23, chain three 24, motor 25, frame 26. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com