Raw-material composition of fermented milk, stirred-type fermented milk and preparation method thereof

A technology of raw material composition and fermented milk, which is applied in the field of preparation of stirred fermented milk, stirred fermented milk, and raw material composition of fermented milk, can solve the problem of the taste of fermented milk paste, the amount of modified starch added and the process. Control and affect the taste of fermented milk, etc., to achieve the effect of silky taste, rich texture and creamy aroma, and even and delicate texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] In another specific embodiment, there is also provided a method for preparing stirred fermented milk, using the above-mentioned raw material composition of fermented milk as a raw material, comprising the following steps:

[0040] mixing the raw milk, the concentrated milk, the cream, the sugar and the concentrated milk protein powder to obtain a mixed liquid;

[0041] The mixed solution is left to stand, homogenized, sterilized, cooled, inoculated with the starter, and fermented until the terminal acidity is 70-85°T to obtain a fermented mixed solution;

[0042] The fermented mixed liquid is filled and cooled twice to obtain stirred fermented milk.

[0043] Since the above-mentioned raw material composition of fermented milk has the above-mentioned beneficial effects, the preparation method of stirred fermented milk using the above-mentioned raw material composition as a raw material also has the above-mentioned beneficial effects correspondingly, and will not be repea...

Embodiment 1

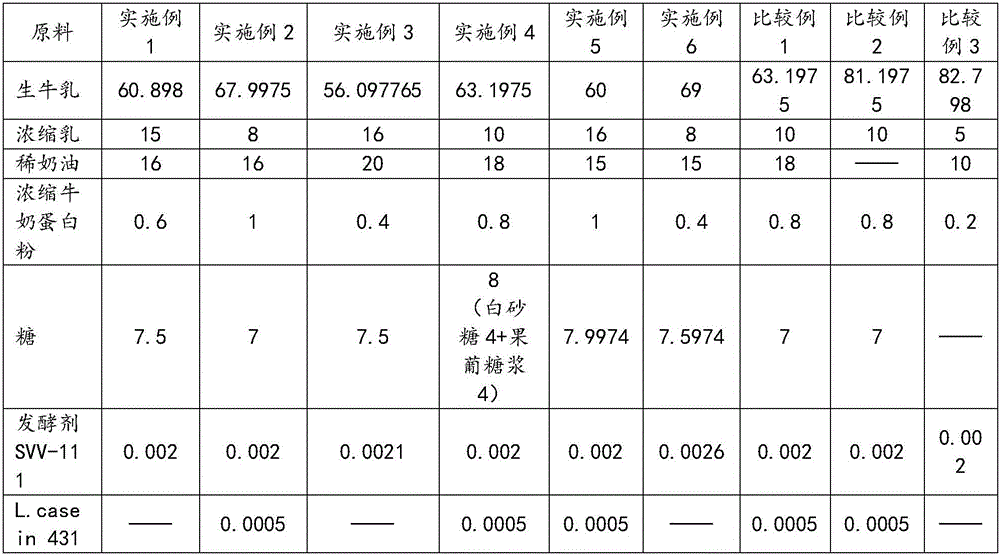

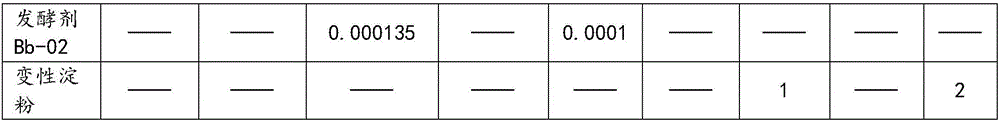

[0059] Carry out proportioning according to the embodiment 1 in table 1.

[0060] 1) Preheat raw milk, concentrated milk, cream, concentrated milk protein powder and white sugar to 50°C and mix well;

[0061] 2) Cool to 5°C, stop stirring, and let it stand for 5 hours; homogenize at 70°C and 18MPa; sterilize at 110°C for 300 seconds; put the sterilized material into a milk buffer tank and cool to 37°C, inoculate the starter SVV -111 (including Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus), ferment at 37°C for 6.5 hours until the acidity reaches 75°T;

[0062] 3) Aseptic filling is performed when the temperature drops to 15° C., cooled to 6° C. to obtain stirred fermented milk.

[0063] Test results: the protein content is 3.3%, the fat content is 8.8%, and the solid content is 24.5%.

Embodiment 2

[0065] Carry out proportioning according to embodiment 2 in table 1.

[0066] 1) Preheat raw milk, concentrated milk, cream, concentrated milk protein powder and white sugar to 60°C and mix well;

[0067] 2) Cool to 5°C and stop stirring, let it stand for 6 hours, homogenize at 70°C and 18MPa, sterilize at 110°C for 300 seconds, put the sterilized material into a milk buffer tank and cool to 39°C, inoculate the starter SVV -111 (including Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus), L.casein 431 (including Lactobacillus casein), ferment at 39°C for 6 hours until the acidity reaches 75°T;

[0068] 3) Aseptic filling is performed when the temperature drops to 20° C., cooled to 2° C. to obtain stirred fermented milk.

[0069] Test results: the protein content is 3.5%, the fat content is 8.7%, and the solid content is 23.86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com