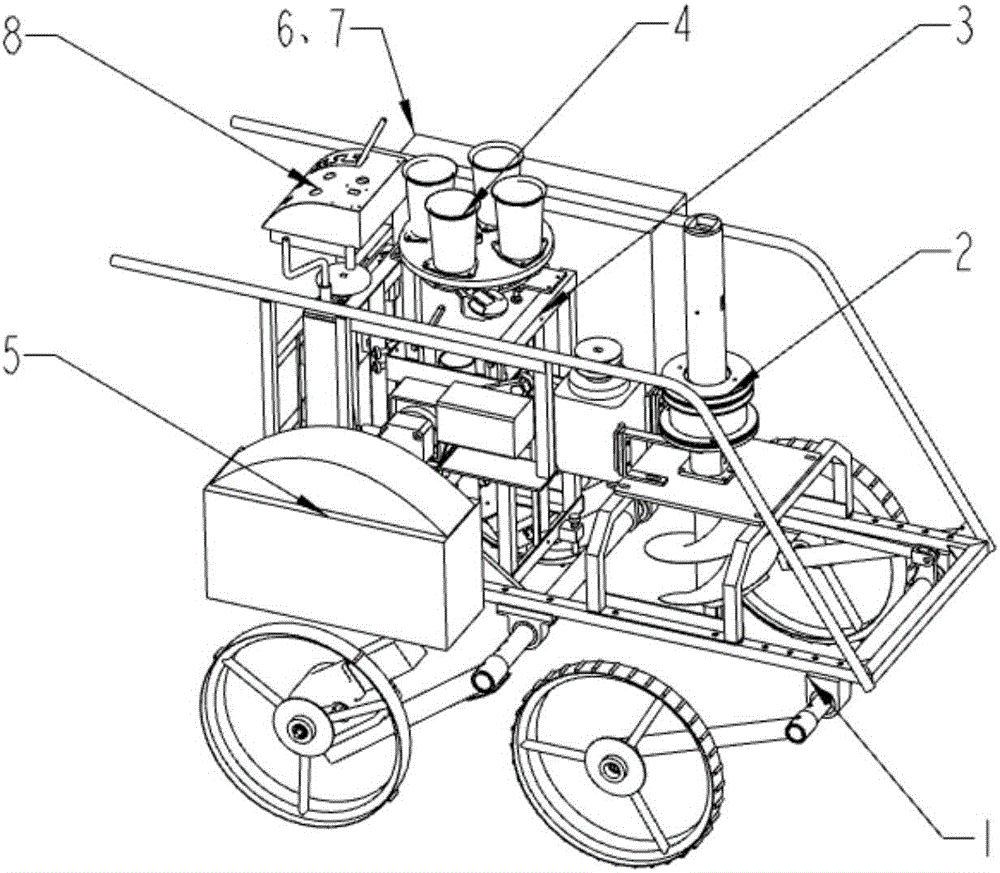

Oil-electricity-type rotary pond digging self-propelled tobacco seedling transplanter

A transplanting machine, self-propelled technology, applied in the direction of transplanting machinery, planting methods, agriculture, etc., can solve the problems of high planting costs, low production efficiency, and difficult economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

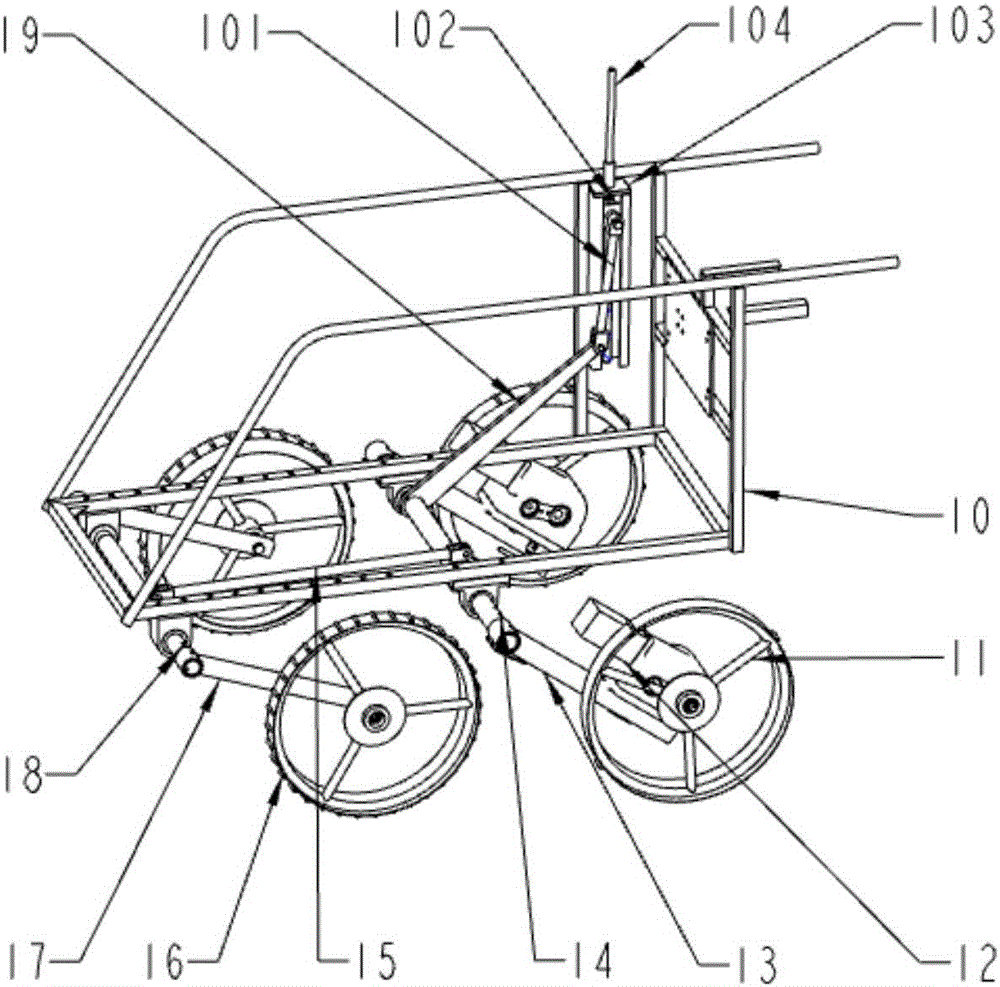

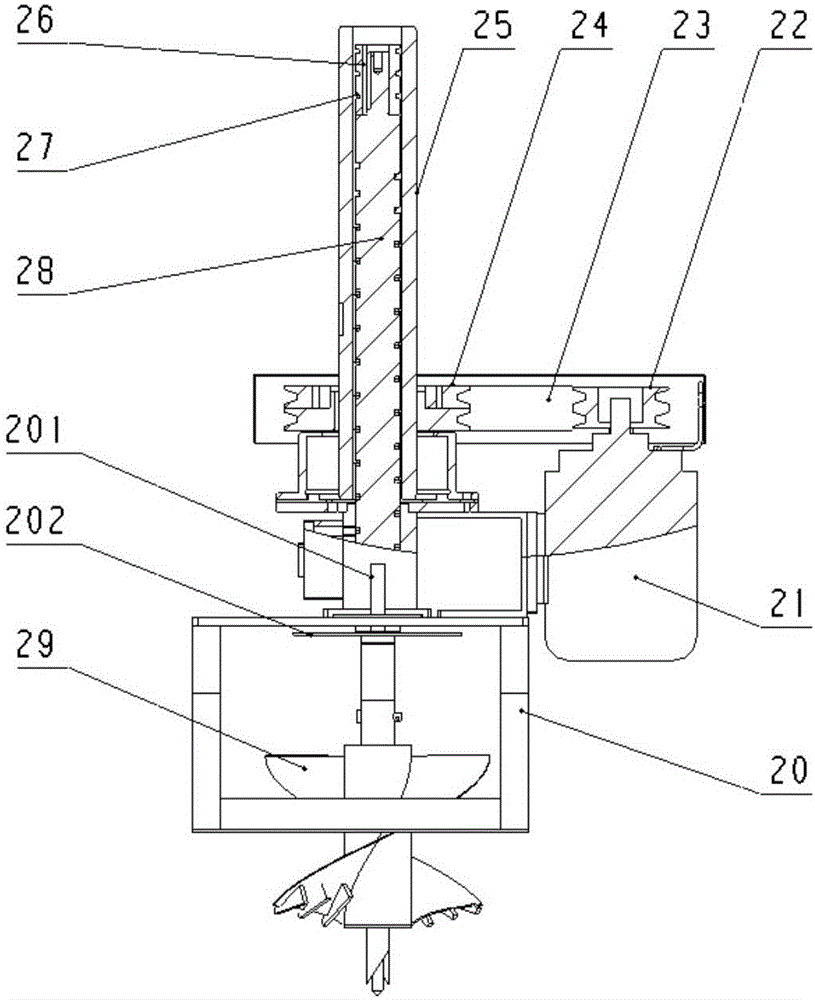

[0058] Embodiment 1: As for the transplanting machine, in the farmland where the ridges have been raised by rotary tillage, according to the ridge specifications of the farmland, use the handle 104 on the adjustable chassis frame 1 to adjust the height of the frame so that the ponds on the rotary pond making mechanism 2 Device 29 is moderate from the height of ridge, guarantees that the depth of playing pond meets the requirements. Then adjust the height of the planter (301) by adjusting the adjustment handle 34 on the transplanting mechanism 3 to adjust the depth of transplanting, thereby adjusting the depth of planting tobacco seedlings.

Embodiment 2

[0059] Embodiment 2: after the gasoline generator 5 is started manually, the AC voltage (58V / 50Hz) that the gasoline generator 5 sends is delivered to the voltage stabilizing circuit module in the intelligent control cabinet 7 by cables, and is rectified, After filtering and voltage stabilization, a stable DC voltage is obtained. The voltage value of the DC power can be adjusted between 48V and 56V, and generally adjusted to 53V. The DC power supply is used as all the power for the machine to run. The direct current output by the voltage stabilizing circuit module is connected to the main power line of the intelligent control cabinet 7 through a 25A fuse.

Embodiment 3

[0060] Embodiment 3: In the intelligent control cabinet 7, the PLC controller 71 is a high-performance PLC of Mitsubishi Corporation, and its model is FX3U-48MT / DS. It has 24 input points and 24 output points, and the DC 24V power supply. It is the logic and intelligent controller of the system, which accepts the instructions sent by the control mechanism to make the machine run according to the operator's requirements. It controls the start and stop sequence, rotation speed and rotation direction of each motor by controlling the drivers of each motor. While the machine is running, it also monitors the action and status of the machine, and converts the fault of the machine into an alarm code to inform the operator. The four-channel analog / digital (A / D) conversion module 72, which is also a product of Mitsubishi, can be used in combination with the FX3U series PLC, and the model is: FX3U-4AD-ADP. It converts the given speed from the control mechanism 8 and the voltage and curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com