A simulation experiment device and working method of natural gas hydrate depressurization exploitation

A simulated experimental device and hydrate technology, which is applied in the fields of mining fluids, coal gasification, and earthwork drilling, can solve the problems of complex and changeable mining environment, lack of simulated borehole monitoring, and lack of simulated boreholes for hydrates, etc. Achieve the effect of saving equipment cost and meeting the experimental requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

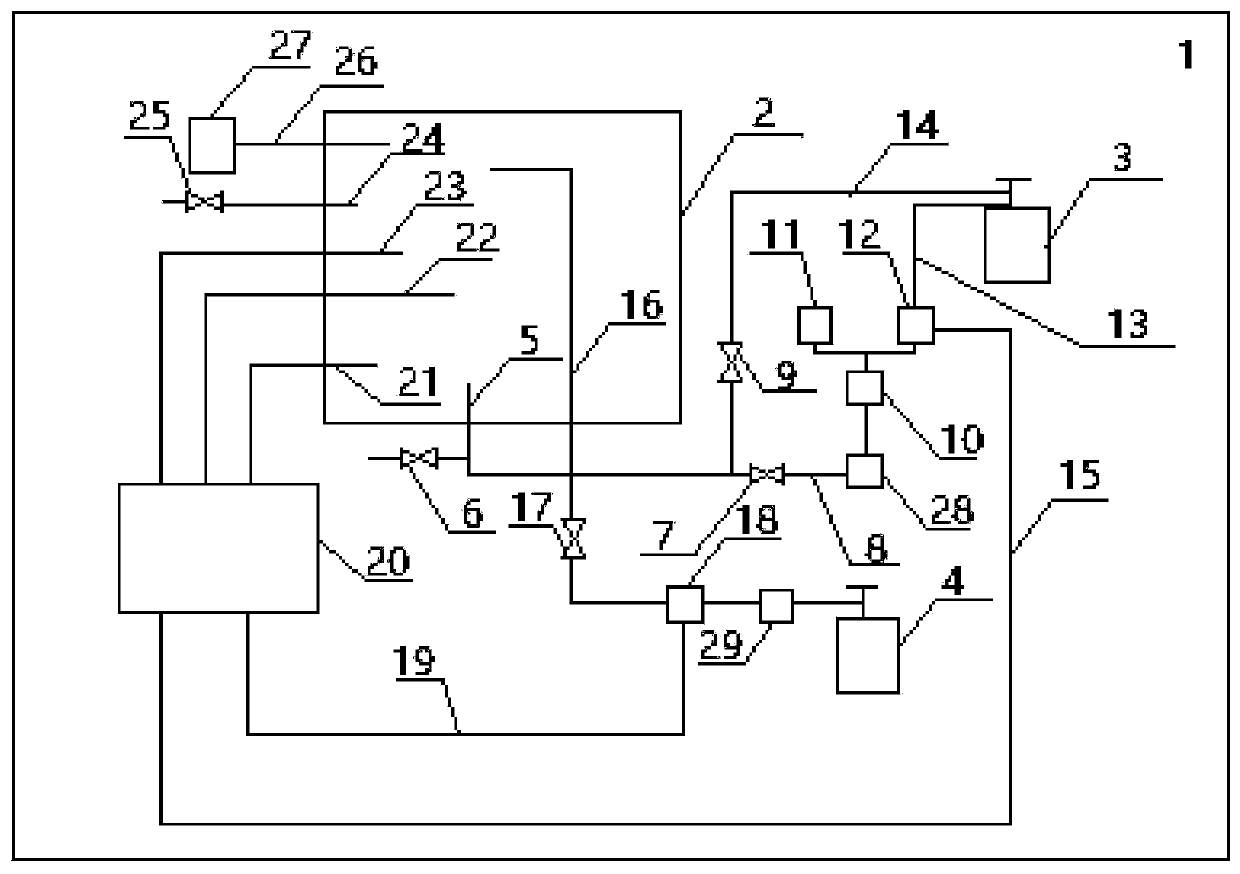

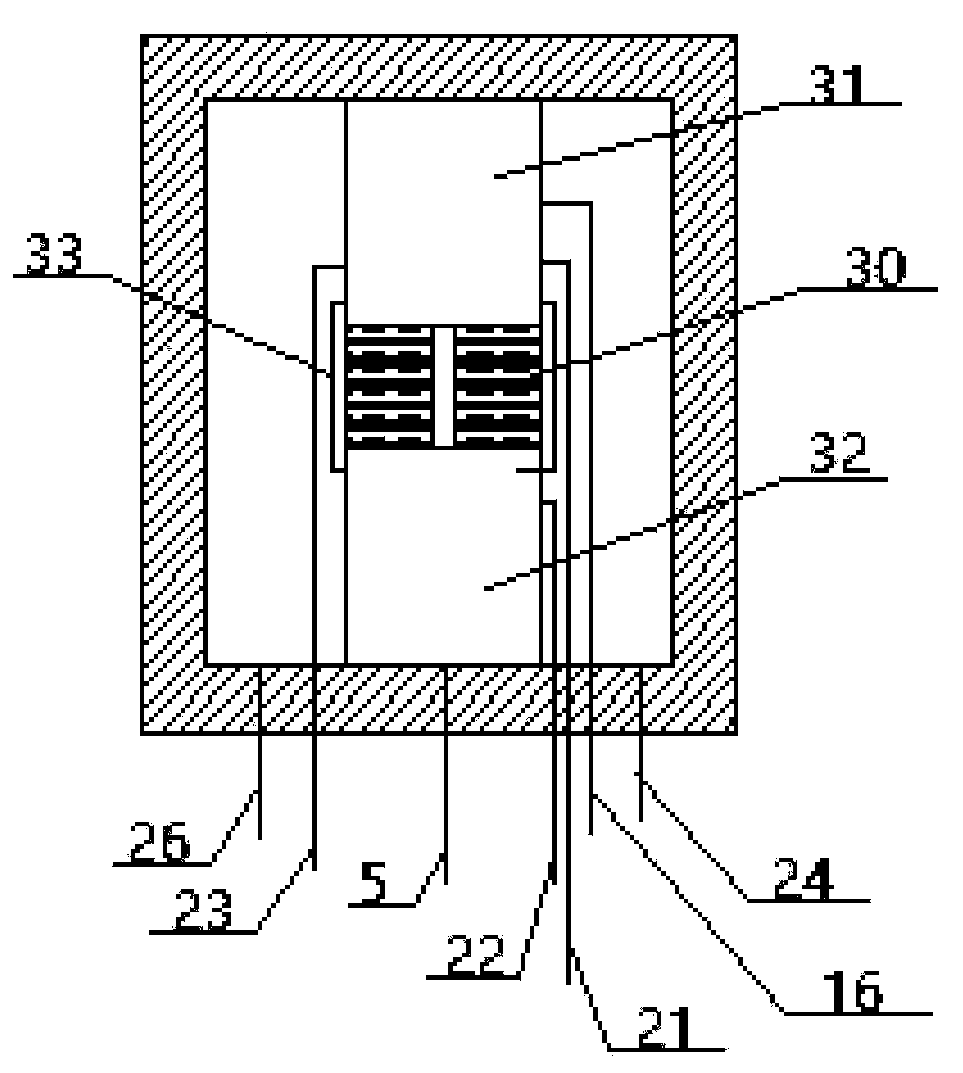

[0049] A natural gas hydrate decompression mining simulation experiment device, including a reactor 2, a confining pressure pump system connected to the reactor 2, a gas supply system, an exhaust system and a data acquisition system; To fix the upper indenter 31 and the lower indenter 32 of the experimental core 30, an oil separator 33 is arranged around the experimental core 30, and a simulated wellbore is arranged in the center of the experimental core 30.

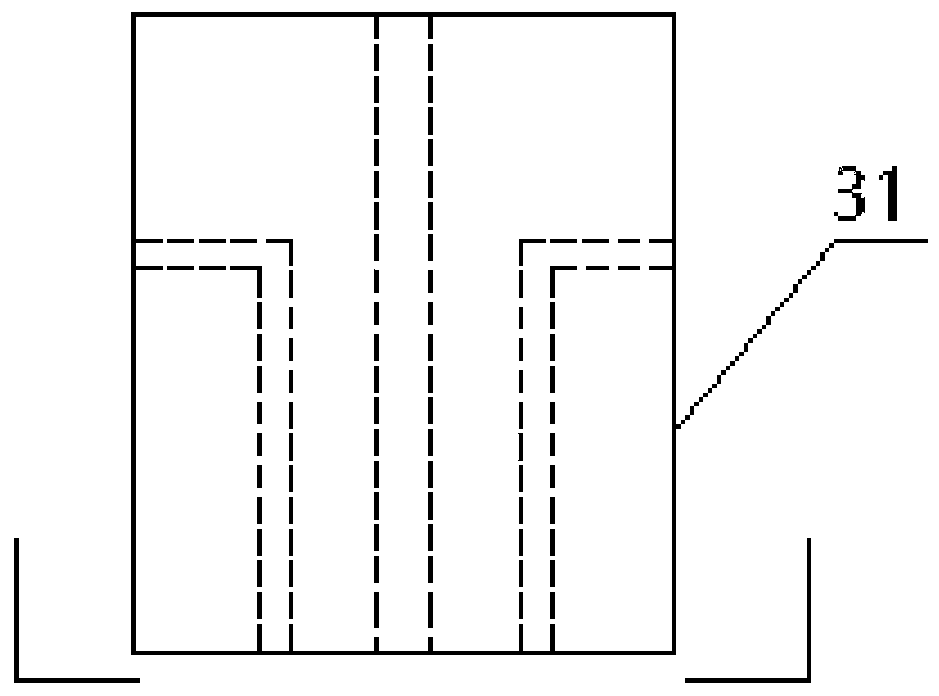

[0050] The cross-sectional diameters of the upper indenter 31 and the lower indenter 32 are both 12.7 cm, which is the same as that of the experimental rock core 30 .

[0051] A through hole for simulating a wellbore is arranged axially in the upper indenter 31, and at least two L-shaped through holes are arranged in the upper indenter 31, and the horizontal section of the L-shaped through hole is connected to the The side wall of the upper indenter is penetrated, and the vertical section of the L-shaped through hole is ...

Embodiment 2

[0054] A natural gas hydrate depressurization recovery simulation experimental device as described in Example 1, the difference is that the experimental device also includes a simulated formation temperature device, which is used to provide simulated formation environment parameters for the reactor and all systems. The device for simulating formation temperature is cold storage 1. The reaction kettle 2 and all systems are arranged in the cold storage 1. The cold storage can realize temperature control from -20°C to room temperature, and all experimental equipment and experimental processes are carried out in the cold storage.

Embodiment 3

[0056] A natural gas hydrate depressurization mining simulation experiment device as described in Examples 1 and 2, the difference is that the confining pressure pump system includes a confining pressure pump 27 connected to the reaction kettle 2 through the seventh high-pressure pipeline 26 .

[0057] The gas supply system is connected to the methane gas source 4 connected to the reactor 2 through the fifth high-pressure pipeline 16, and the second shut-off valve 17, the second gas flow meter 18 and the decompression valve 17 are arranged on the fifth high-pressure pipeline 16. Valve 29.

[0058] The discharge system includes a second vent valve 25 connected to the reactor 2 through the sixth high-pressure pipeline 24, and a recovery air bag 3 connected to the reactor 2 through the first high-pressure pipeline 5: in the first high-pressure pipeline 5 is provided with a vacuum valve 6; the first high-pressure pipeline 5 is also connected to the recovery air bag 3 through a fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com