Tool for rapidly avoiding and resetting three-coordinate measurement head replacing frame

A three-coordinate and measuring head technology, which is applied in the direction of measuring devices and instruments, can solve the problems of damage to the installation hole of the three-coordinate machine detection platform, affect the three-coordinate detection, and consume a lot of time, and achieve low production difficulty, simple structure, The effect of easy and convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

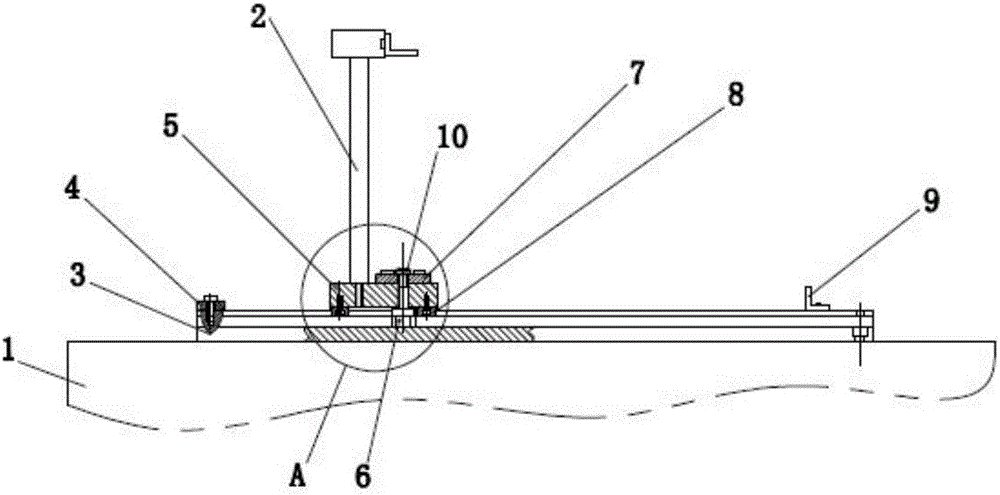

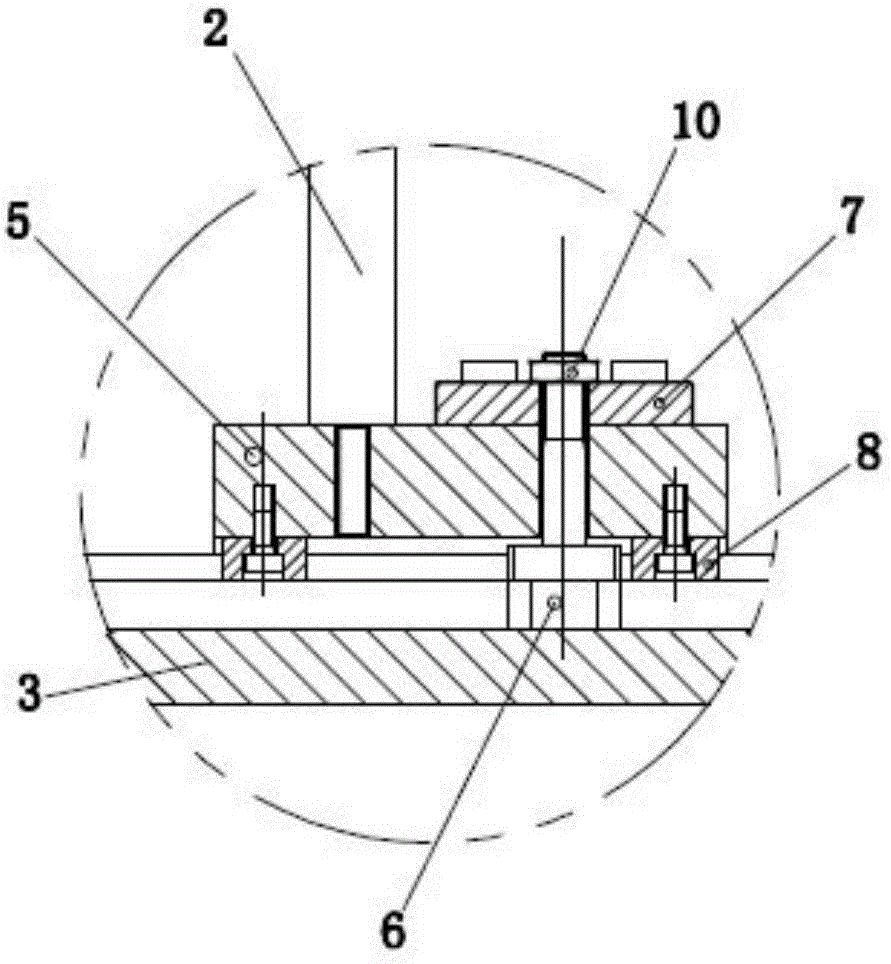

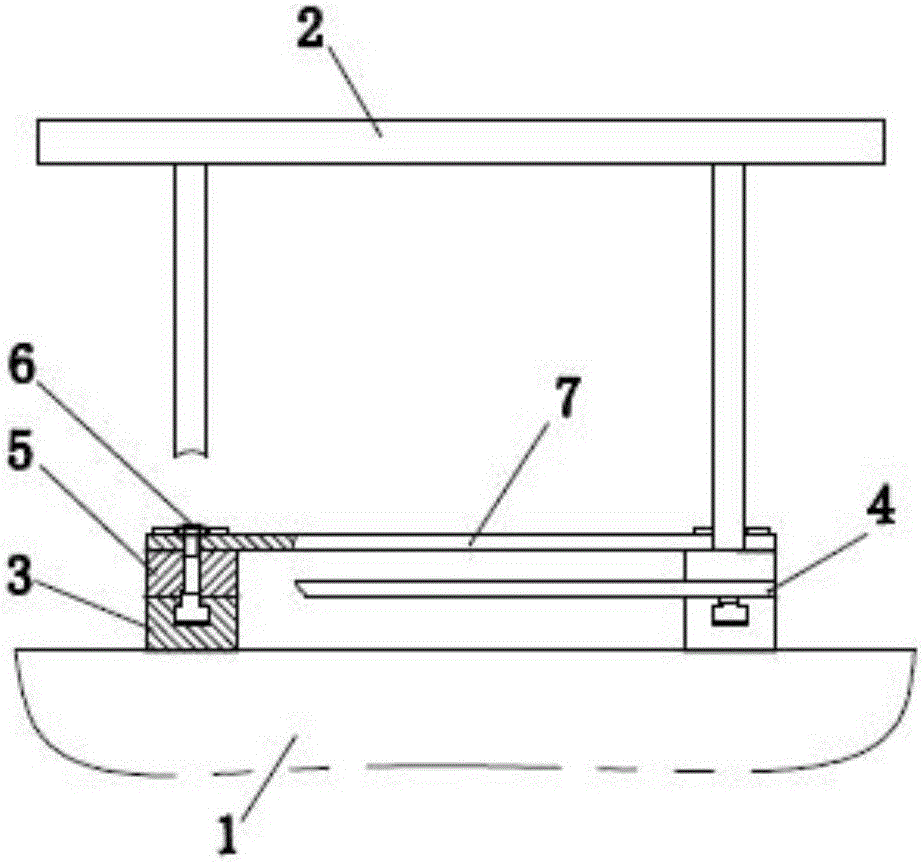

[0036] Specific embodiments of the present invention are as follows Figure 1 to Figure 3 As shown in the figure, a tooling for quickly giving way and repositioning a three-coordinate probe replacement frame includes a detection platform 1, and a probe replacement frame 2 is arranged above the detection platform 1; the tooling includes a set on the detection platform. A translation mechanism between 1 and the probe replacement frame 2 and enabling the probe replacement frame 2 to move in the horizontal direction on the inspection platform 1 . The tooling can greatly expand the installation range of the probe replacement frame 2, and the movement is simple and convenient, saving time and effort; the probe replacement frame 2 is reset accurately, and it does not need to be leveled and positioned again, and it also avoids frequent disassembly and assembly to zero damage to components.

[0037] The translation mechanism includes a matching guide rail 3 and a slider 5, the guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com