Impellers for exhaust turbochargers

An exhaust turbine, supercharger technology, applied in the direction of parts of pumping devices for elastic fluids, machines/engines, supporting elements of blades, etc., can solve the problem of reducing high tensile stress, unsatisfactory load, limited And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

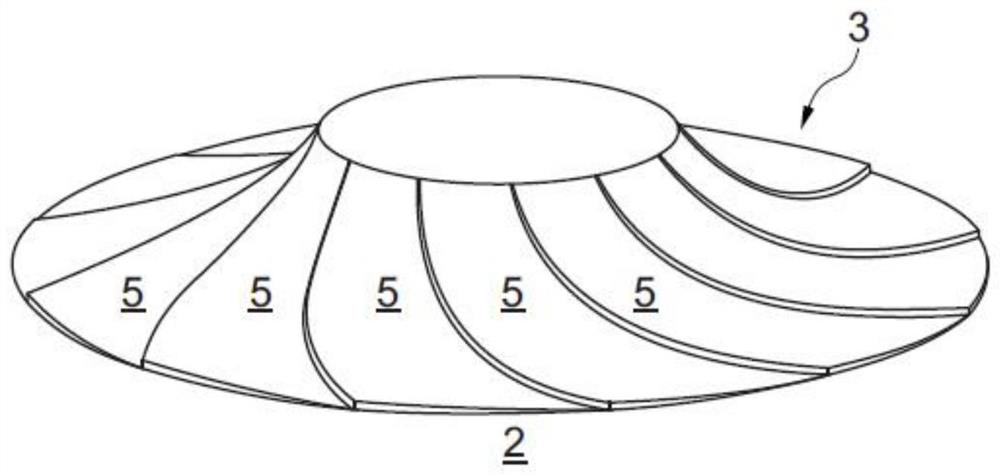

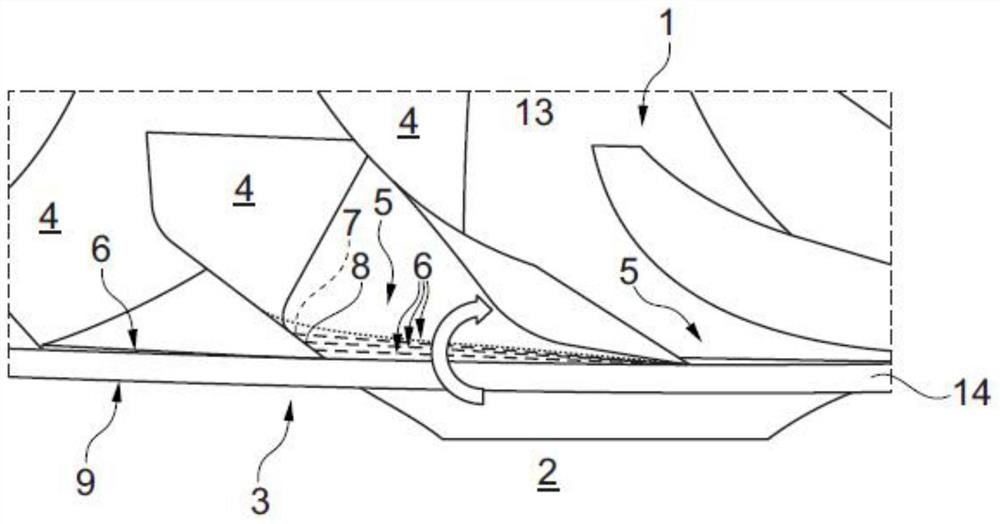

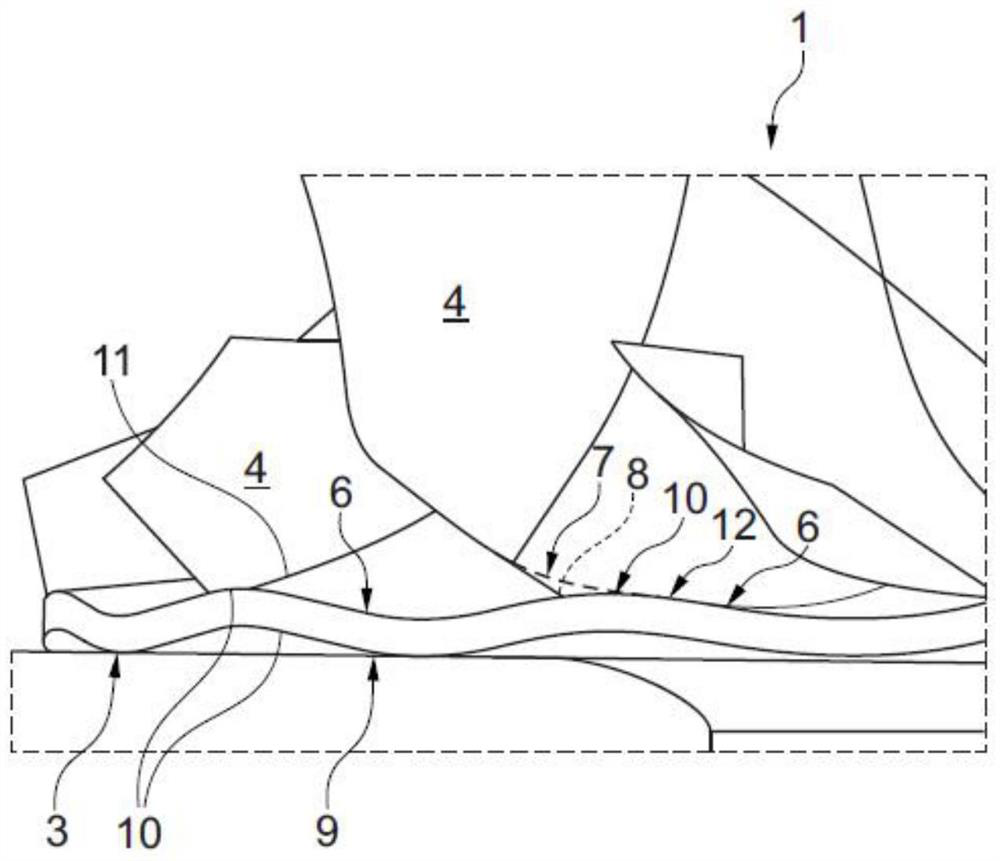

[0025] according to Figure 1 to Figure 5 , the impeller 1 according to the invention for an exhaust-gas turbocharger 2 has a hub body 3 and blades 4 arranged on said hub body 3 . figure 1 Only the hub body 3 is shown, not the associated blades 4 . In order to subsequently be able to optimize the impeller 1 according to the invention with regard to the stresses occurring in the region of the transition 7 between the individual blades 4 and the hub body 3, two alternative embodiments of the hub body 3 are provided, the first The replacement example is shown in figure 1 with figure 2 , while the second substitution example is shown in Figure 3 to Figure 5 middle.

[0026] according to figure 1 with figure 2 , the hub body 3 is here configured according to the invention as a polygon with a number of portions 5 inclined relative to each other, corresponding in number to the number of blades 4 . In this paper, each section 5 (see also figure 2 ) preferably has at least ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com