Left platform assembly for heavy mine vehicle

A technology for heavy-duty mines and platforms, applied in vehicle components, superstructures and superstructures of trucks, etc., can solve the problems of affecting on-board capacity, low safety, and large cab space, and achieve increased on-board capacity, reduced Small footprint, the effect of decorating the exterior of the car

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, the present invention is described in further detail:

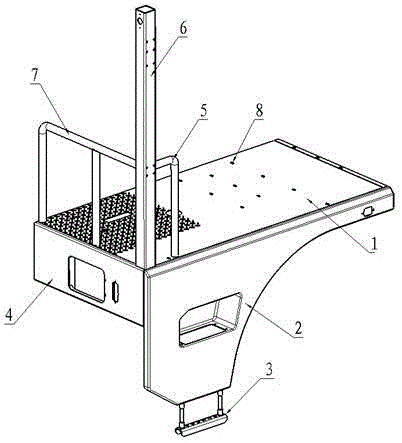

[0011] Such as figure 1 As shown, a left platform assembly for a heavy-duty mine vehicle of the present invention includes a rectangular patterned steel plate platform 1, a pedal 2 is connected to the bottom of the right long side of the patterned steel plate platform 1, and the front side of the patterned steel plate platform 1 The front left headlight decorative plate 4 is arranged below the short side, a railing 7 is provided above the short side of the front side of the patterned steel plate platform 1, and a handrail 5 is provided at the front end of the right long side of the patterned steel plate platform 1. Between the handrail 5 and the railing 7 A rearview mirror installation column 6 is arranged above the treaded steel plate platform 1 in between, and a mounting hole 8 is provided on the surface of the treaded steel plate platform 1 . A movable pedal 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com