Special equipment for tipping and replacing large slab crystallizers in the aluminum processing industry

A special equipment and aluminum processing technology, applied in the field of special equipment for large flat ingot mold tipping and replacement, can solve problems such as affecting production efficiency, high circulating water temperature, and safety hazards, etc., to improve work efficiency and production efficiency, ensure The effect of safe operation and prevention of sudden drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

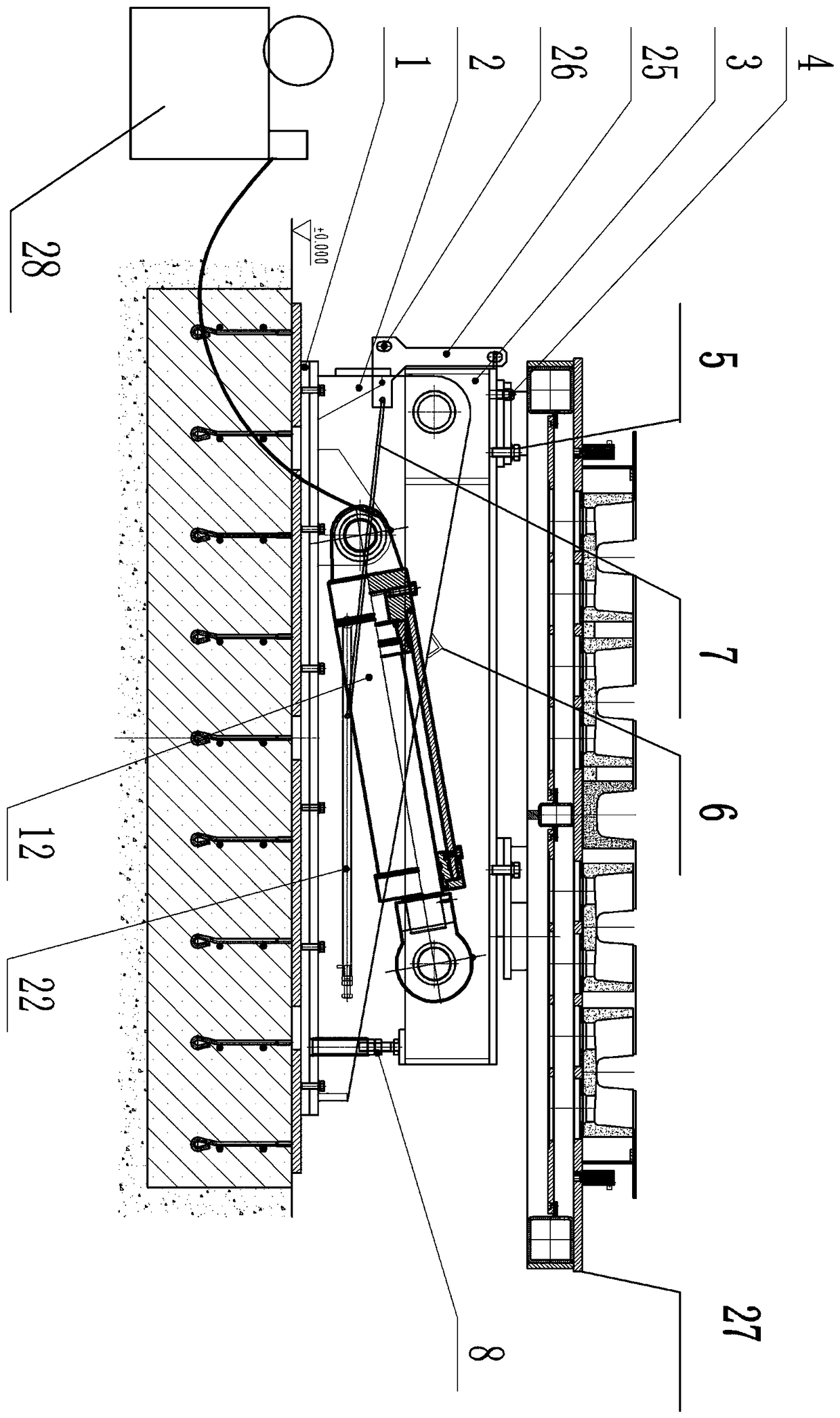

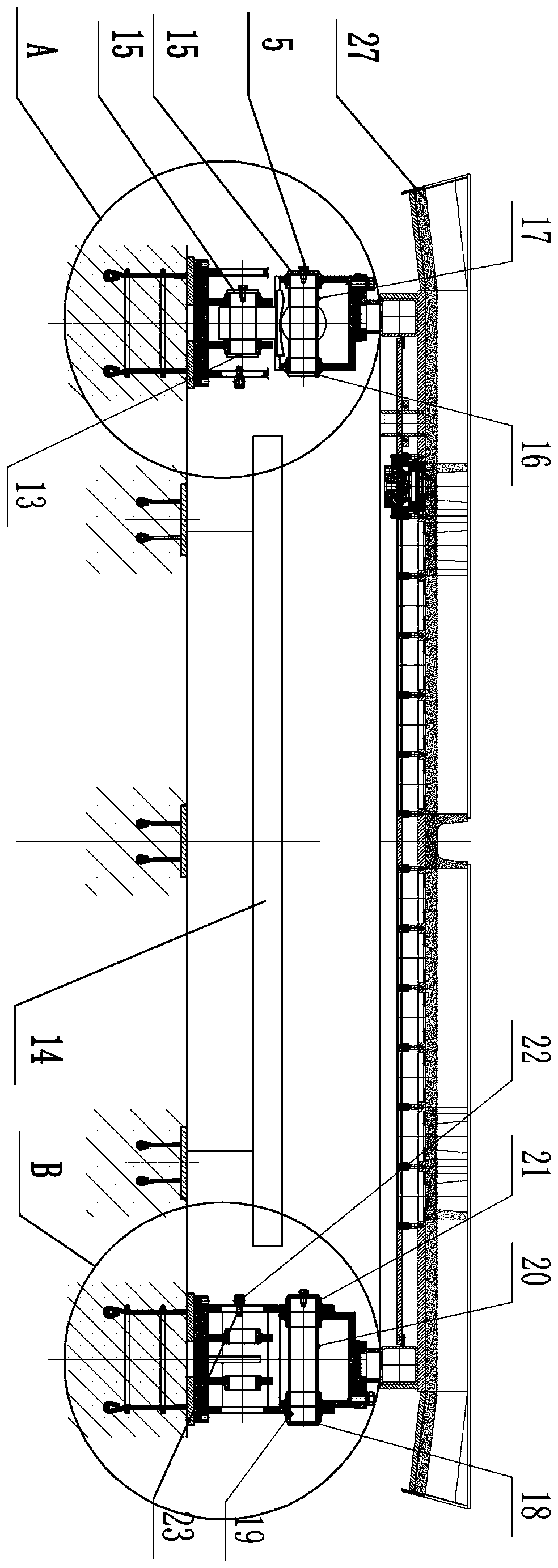

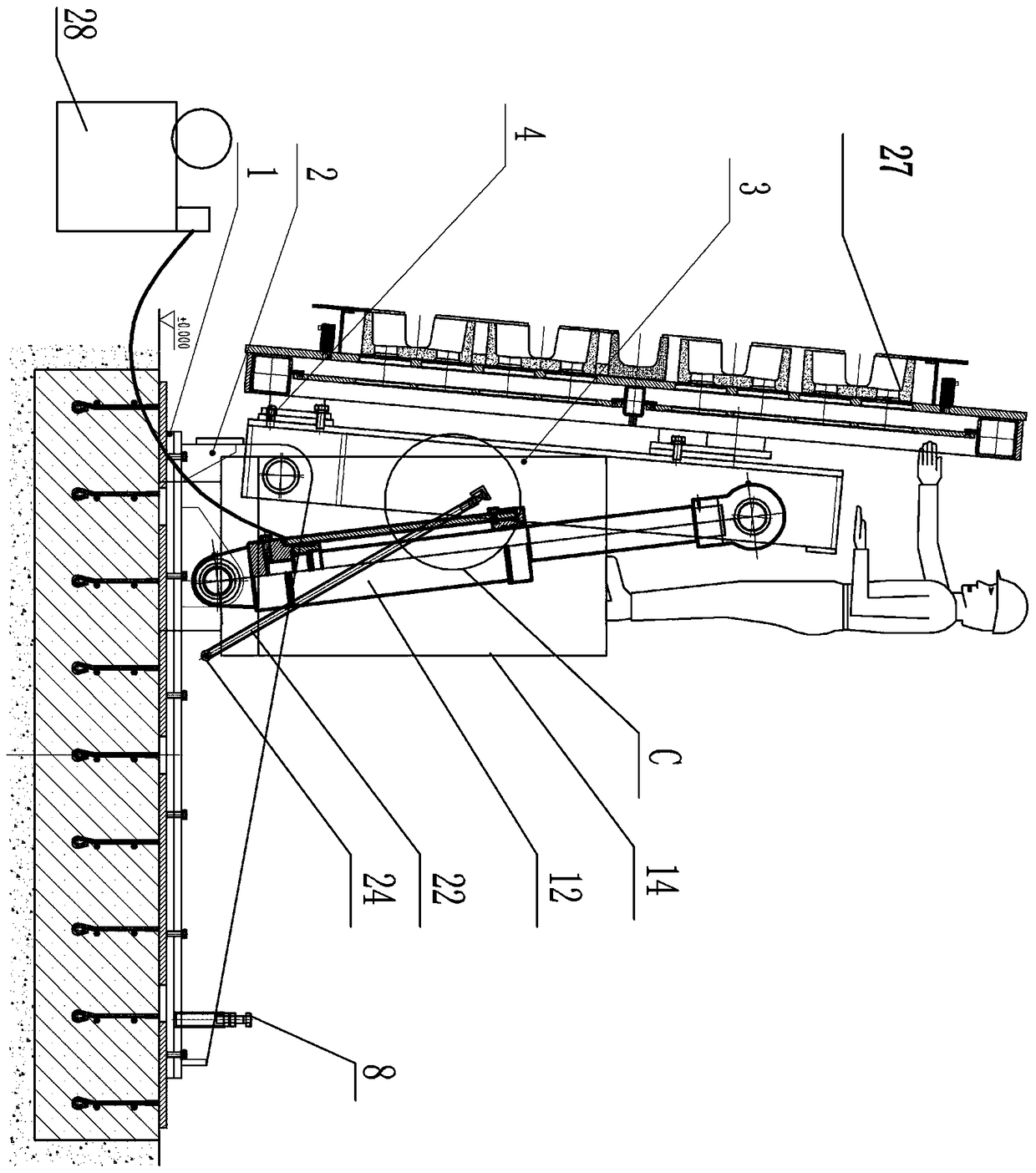

[0026] Example: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 , in the figure, 1-base fixing plate, 2-base, 3-tilting beam, 4-location pin, 5-hex bolt, 6-limit baffle, 7-connecting rod, 8-tilting beam pillar, 12 -Hydraulic cylinder, 13-Hydraulic cylinder pin 1, 14-Elevating maintenance platform, 15-Pin gland, 16-Hydraulic cylinder pin 2, 17-Space sleeve 2, 18-Base fixing pin, 19-Self-lubricating bearing , 20-spacer sleeve 1, 21-welding sleeve, 22-protective strut device, 23-cotter pin, 24-strut pin shaft, 25-travel switch bracket, 26-inductive proximity switch, 27-flat ingot crystallizer Casting platform, 28-electric hydraulic station.

[0027] The special equipment for tipping and replacing large flat ingot crystallizers in the aluminum processing industry, including base 2, tilting beam 3 and hydraulic device, two bases 2 are arranged on the base fixing plate 1 in parallel, base 2, tilting beam 3 It is hinged with the hydraulic device and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com