A process and device for press-fitting and flanging of subway pivoting arm nodes

A press-fitting device and flanging technology, which is applied in the field of rail vehicle manufacturing, can solve the problems of complex flanging size and inaccuracy of the press-fitting flanging device, and achieve the effects of saving operation labor cost, accurate size and simple device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

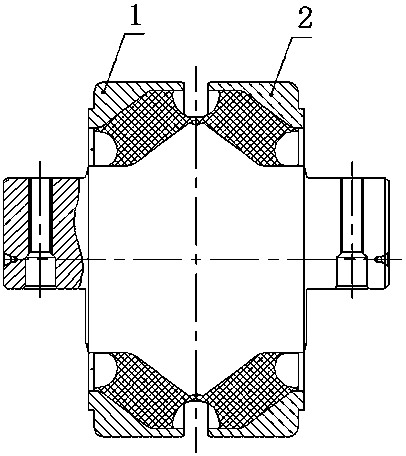

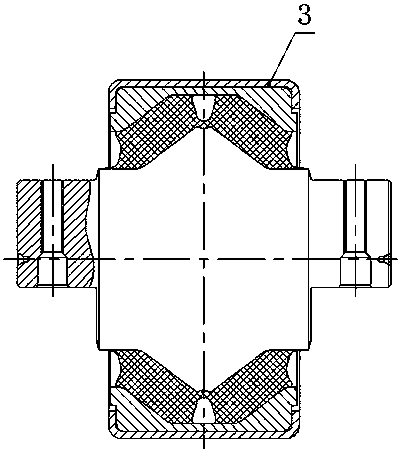

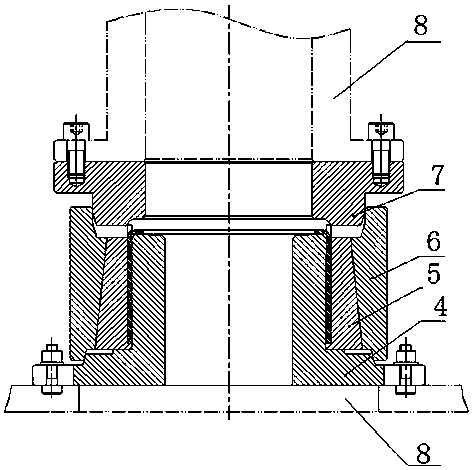

[0025] Such as Figure 3 to Figure 5 As shown in the figure, a press-fitting and flanging device for a rotating arm node of a subway includes a rotating arm node jacket, three one-end flanging devices, a rotating arm node pressing device, and a rotating arm node jacket, and three other-end flanging devices. The three one-end flanging devices of the pivoting arm node cover include machine platform one 8, a flanging base 4, a flanging two-lobe mold 5, a flanging middle mold 6, and a flanging pressure head 7; the flanging base is installed on the machine Table one, 8 lower plates, one upper (lower plate one is located at the lower part of machine one), the flanging two-part mold is installed on the flanging base, and there is a space between the flanging base and the two flanging molds that can be put into the rotating arm In the vertical gap of the joint jacket three, the flanging middle mold is closely attached to the outside of the two flaps of the flanging mold; the flanging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com