A dispensing device for electronic components

A technology of electronic components and dispensing devices, which is applied to the device and coating of the surface coating liquid, can solve the problems of poor dispensing effect and low work efficiency, and achieve time saving, firm position and manpower saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

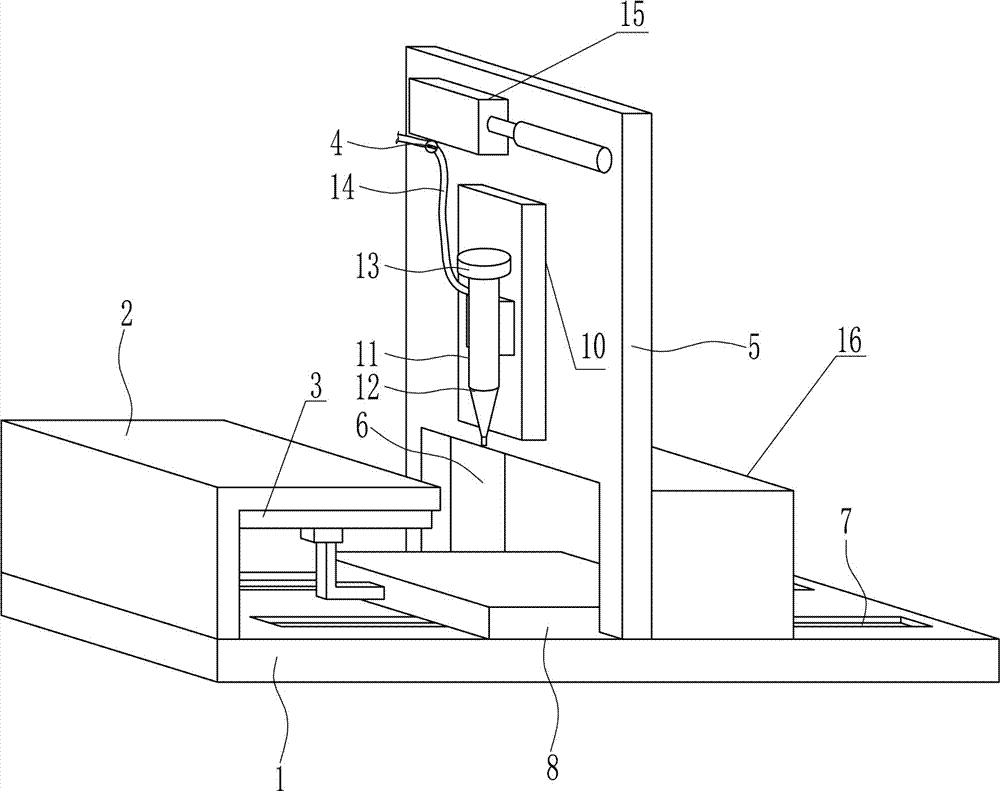

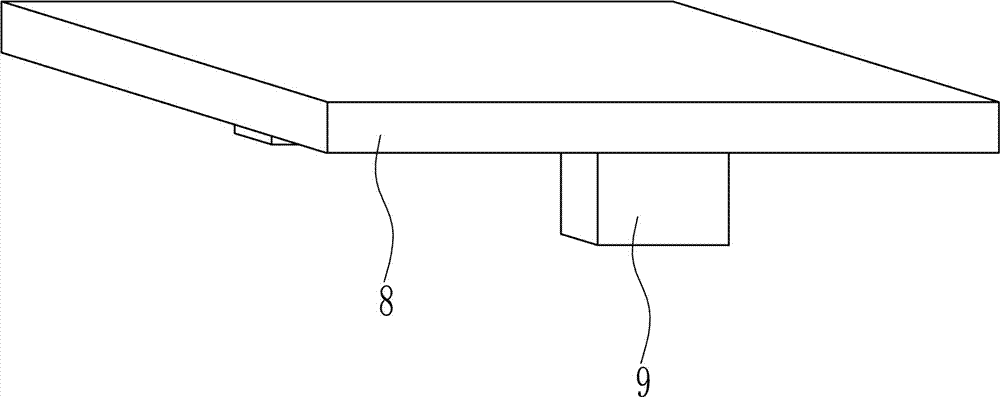

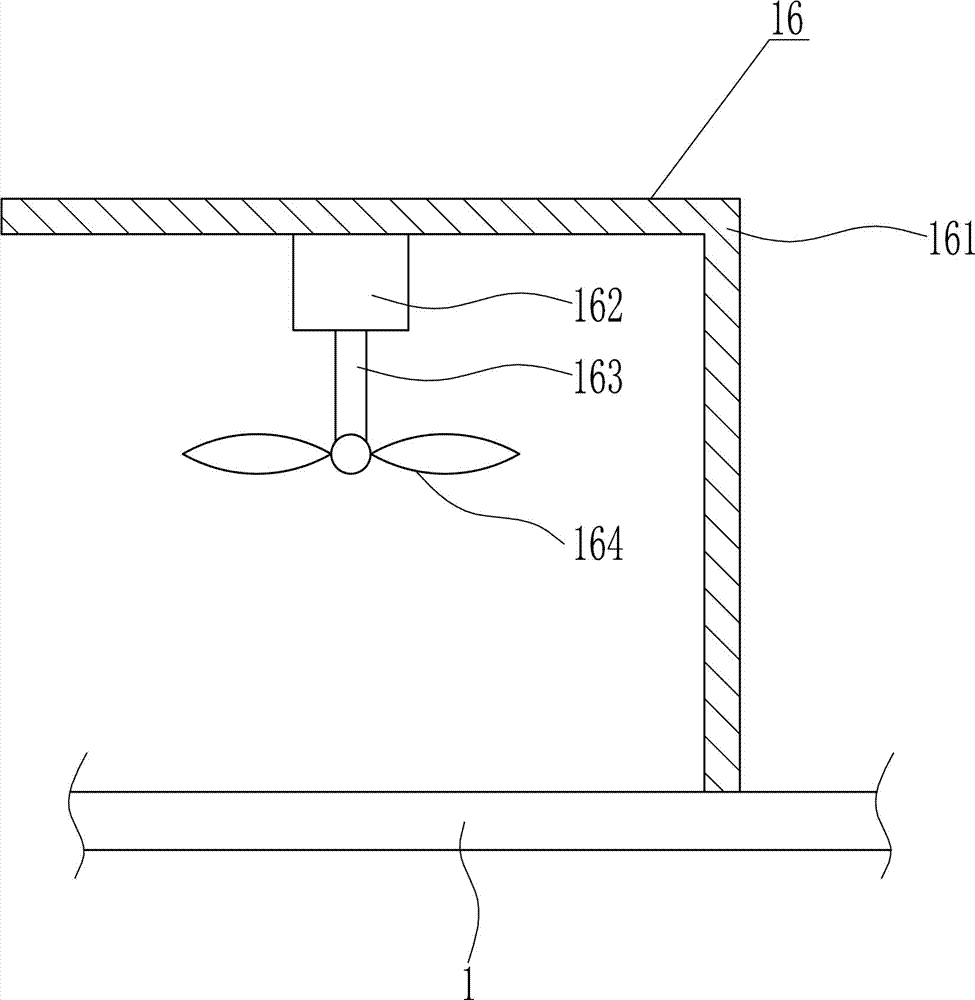

[0038] A dispensing device for electronic components, such as Figure 1-9 As shown, it includes bottom plate 1, L-shaped support plate 2, left and right moving device 3, pressure regulating valve 4, vertical plate 5, placing plate 8, slider 9, up and down moving device 10, glue tube 11, dispensing syringe 12. Cover 13, high-pressure gas pipe 14 and pressure regulating valve 4. L-shaped support plate 2 is welded on the left end of the top of bottom plate 1. Vertical plate 5 is welded vertically in the middle of the top of bottom plate 1. Opening 6 is opened on the lower part of vertical plate 5. On bottom plate 1 A chute 7 is opened front and rear symmetrically, and a slide block 9 is slidably arranged in the chute 7, and the slide block 9 is slidably matched with the chute 7. The top of the slide block 9 is welded with a placement plate 8, and the placement plate 8 is located at the top of the bottom plate 1. The plate 8 cooperates with the opening 6, and the inner horizontal ...

Embodiment 2

[0040] A dispensing device for electronic components, such as Figure 1-9 As shown, it includes bottom plate 1, L-shaped support plate 2, left and right moving device 3, pressure regulating valve 4, vertical plate 5, placing plate 8, slider 9, up and down moving device 10, glue tube 11, dispensing syringe 12. Cover 13, high-pressure gas pipe 14 and pressure regulating valve 4. L-shaped support plate 2 is welded on the left end of the top of bottom plate 1. Vertical plate 5 is welded vertically in the middle of the top of bottom plate 1. Opening 6 is opened on the lower part of vertical plate 5. On bottom plate 1 A chute 7 is opened front and rear symmetrically, and a slide block 9 is slidably arranged in the chute 7, and the slide block 9 is slidably matched with the chute 7. The top of the slide block 9 is welded with a placement plate 8, and the placement plate 8 is located at the top of the bottom plate 1. The plate 8 cooperates with the opening 6, and the inner horizontal ...

Embodiment 3

[0043] A dispensing device for electronic components, such as Figure 1-9 As shown, it includes bottom plate 1, L-shaped support plate 2, left and right moving device 3, pressure regulating valve 4, vertical plate 5, placing plate 8, slider 9, up and down moving device 10, glue tube 11, dispensing syringe 12. Cover 13, high-pressure gas pipe 14 and pressure regulating valve 4. L-shaped support plate 2 is welded on the left end of the top of bottom plate 1. Vertical plate 5 is welded vertically in the middle of the top of bottom plate 1. Opening 6 is opened on the lower part of vertical plate 5. On bottom plate 1 A chute 7 is opened front and rear symmetrically, and a slide block 9 is slidably arranged in the chute 7, and the slide block 9 is slidably matched with the chute 7. The top of the slide block 9 is welded with a placement plate 8, and the placement plate 8 is located at the top of the bottom plate 1. The plate 8 cooperates with the opening 6, and the inner horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com