Refrigerator upper beam processing device with flip function

A technology for processing devices and refrigerators, applied in the direction of spraying devices, devices for coating liquid on the surface, coatings, etc., can solve the problems of high safety risks, poor strength of the turning mechanism, etc., and achieve the effect of convenient and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

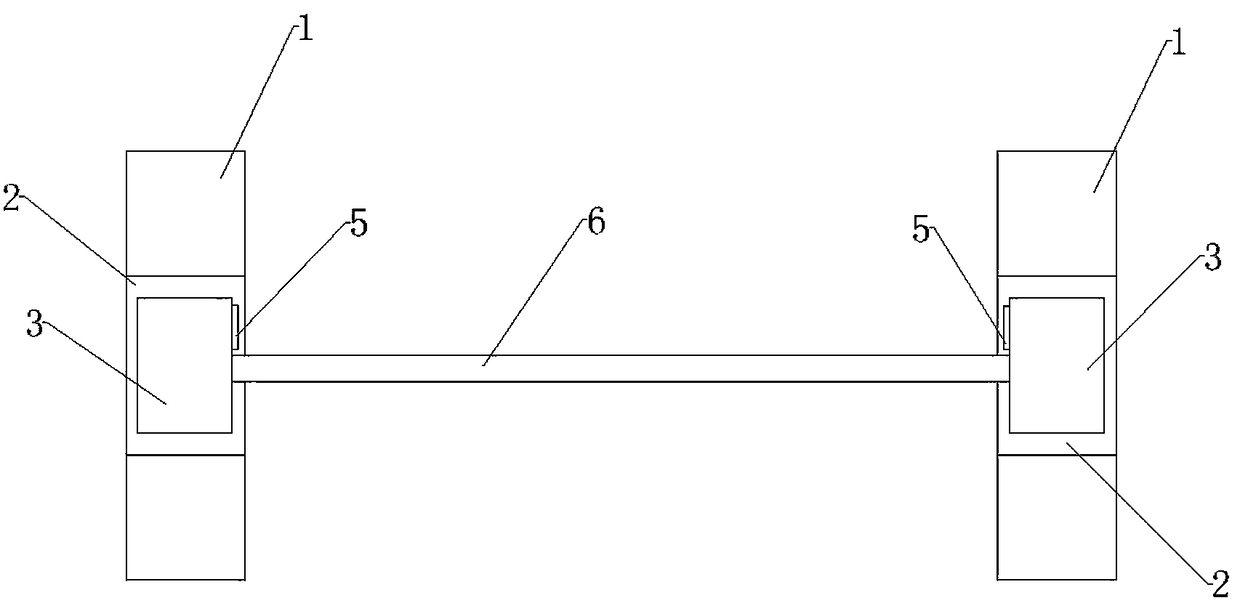

[0025] Such as figure 1 with image 3 As shown: the upper beam processing device of the refrigerator with flip function, including two processing tables 1, the middle part of the processing table 1 is provided with a chute 2, the cross section of the chute 2 is arc-shaped, and the roller 3 is installed in the chute 2, The roller 3 is in contact with the chute 2, and the roller 3 is provided with bristles, and the roller 3 can roll in the chute 2. The upper end of the roller 3 is provided with an opening groove 4 for fixing the upper beam workpiece 6, and the chute 2 is a The side is provided with elastic plate 5, and this elastic plate 5 is arranged on the inner side of two rollers 3, is provided with hairbrush on elastic plate 5.

[0026] The specific operation is as follows: when the upper beam workpiece 6 needs to be processed, insert the upper beam workpiece 6 into the open slot 4, use a spray gun to spray paint on one side of the upper beam workpiece 6 in one direction, ...

Embodiment 2

[0028] Such as figure 2 with image 3 As shown, the width of the roller 3 is less than the width of the chute 2, in order to allow the roller 3 to move its position on the chute 2 according to the length of the upper beam workpiece 6 when rolling. There is an elastic plate 5, and the elastic plate 5 is arranged on the inner side of the two rollers 3. Therefore, after processing, the roller 3 drives the upper beam workpiece 6 to rotate to the position of the elastic plate 5, and the elastic plate 5 intervenes in the opening groove 4, The elastic plate 5 is deformed by stress under the action of the upper beam workpiece 6; in order to restore the original shape, the elastic plate will apply an elastic restoring force to the upper beam workpiece 6, and the upper beam workpiece 6 will be lifted from the roller 3 under the action of the elastic restoring force. Ejection, rather than taking out the upper beam workpiece 6 from the roller 3 artificially.

Embodiment 3

[0030] Such as figure 2 Shown, the length of processing table 1 is generally greater than the length of chute 2, and in present embodiment 3, the length of processing table 1 is 2 times of this chute 2 lengths, the length of processing table 1 is set to the length of chute 2 2 times is for the convenience of placing the sprayed items on the processing table 1. There is no need to add an additional placing table or place it on the ground. If it is placed on the ground, the paint flowing out of the sprayed items will pollute the ground.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com