Movable oil field oily sludge biological tempering separation treatment device

A technology for biological and separation treatment of sludge, applied in the fields of sludge treatment, sludge treatment, biological sludge treatment, etc., can solve the problems of reducing the exudation rate of harmful substances, and the degradation efficiency needs to be improved, so as to achieve the effect of convenient transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

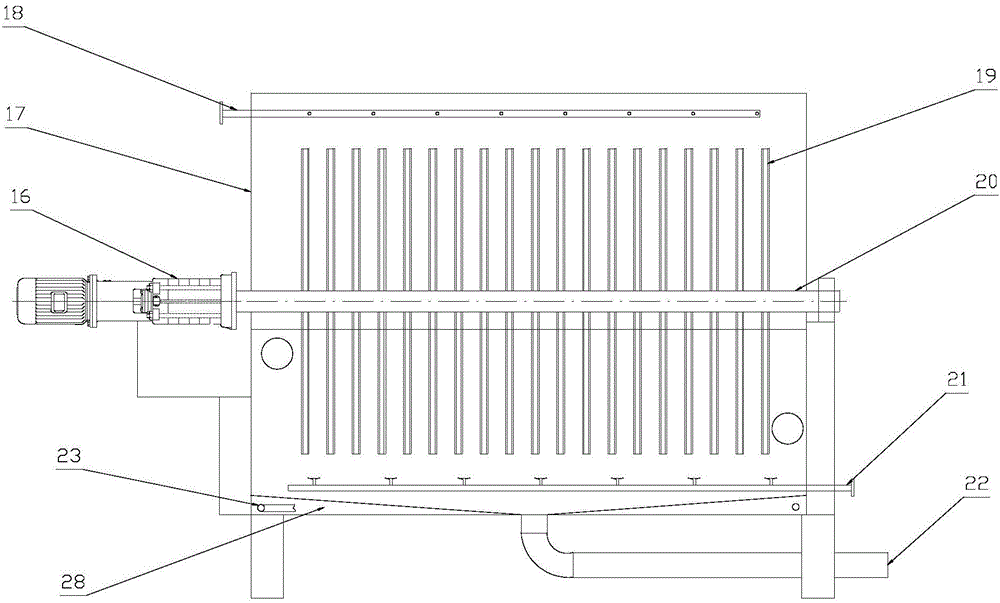

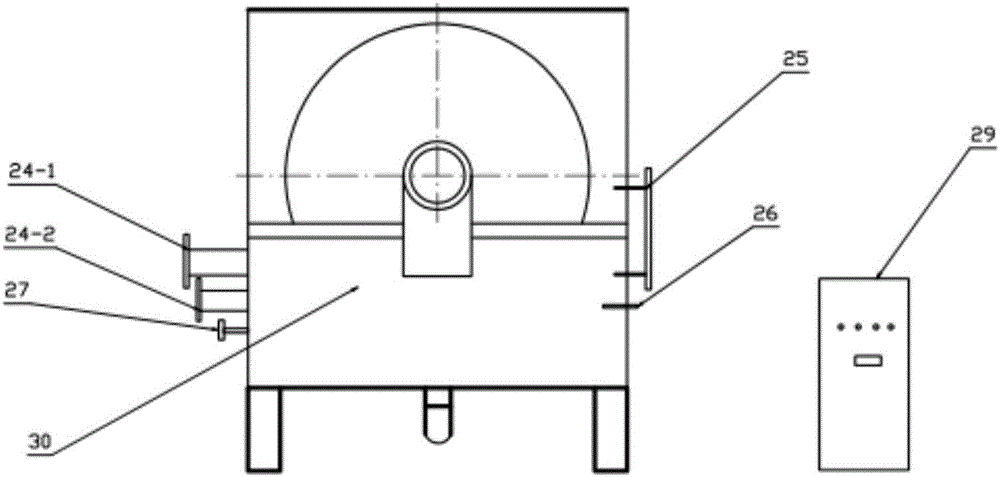

[0023] A mobile oilfield oily sludge biological, conditioning and tempering separation treatment device, the device is divided into pretreatment and screening process section ①, primary oil sludge treatment process section ②, secondary oil, water, mud separation process section ③, biological sludge Treatment process section ④, oil-water separation treatment process section ⑤, mud sand treatment process section ⑥;

[0024] The pretreatment screening process section ① consists of feed screening machine 1, three-stage oil-water screening pool 2, and 2mm vibrating screen 3; the main function of the pretreatment screening process section is to remove large-size sludge particles and change the sludge flow state. The raw material enters the feed screening machine 1, and the sludge enters the hopper through the hopper grille to remove solid particles larger than 20 mm, and removes large-volume stones, waste materials, and woven sundries for external transportation. The screened materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com