A single-layer rotating stage car

A stage car, single-layer technology, applied in the field of single-layer rotary stage car, can solve the problems of stage instability, poor flatness, affecting performance effects, etc., to achieve diversified performance forms, lower requirements for ground flatness, and adaptability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

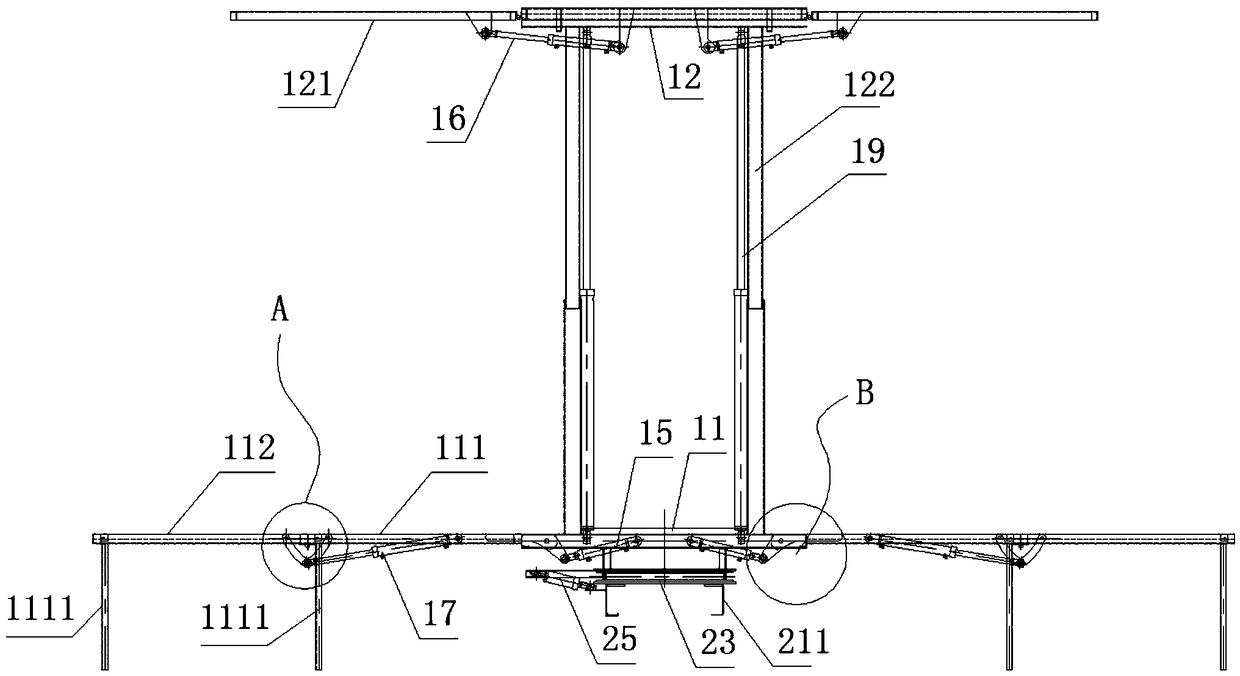

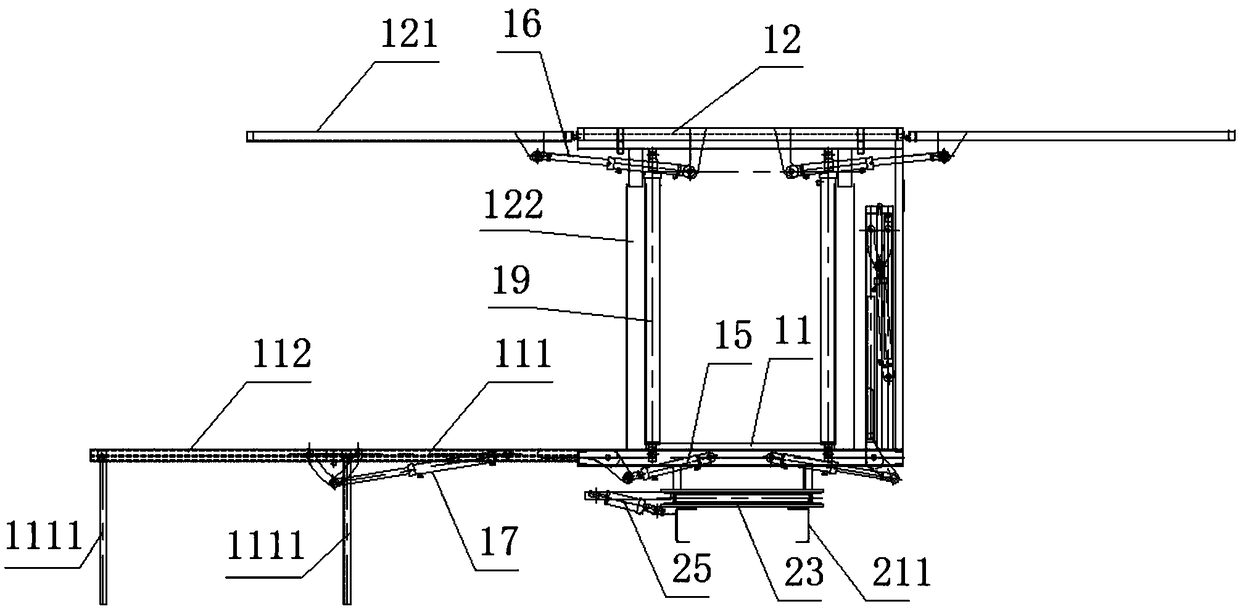

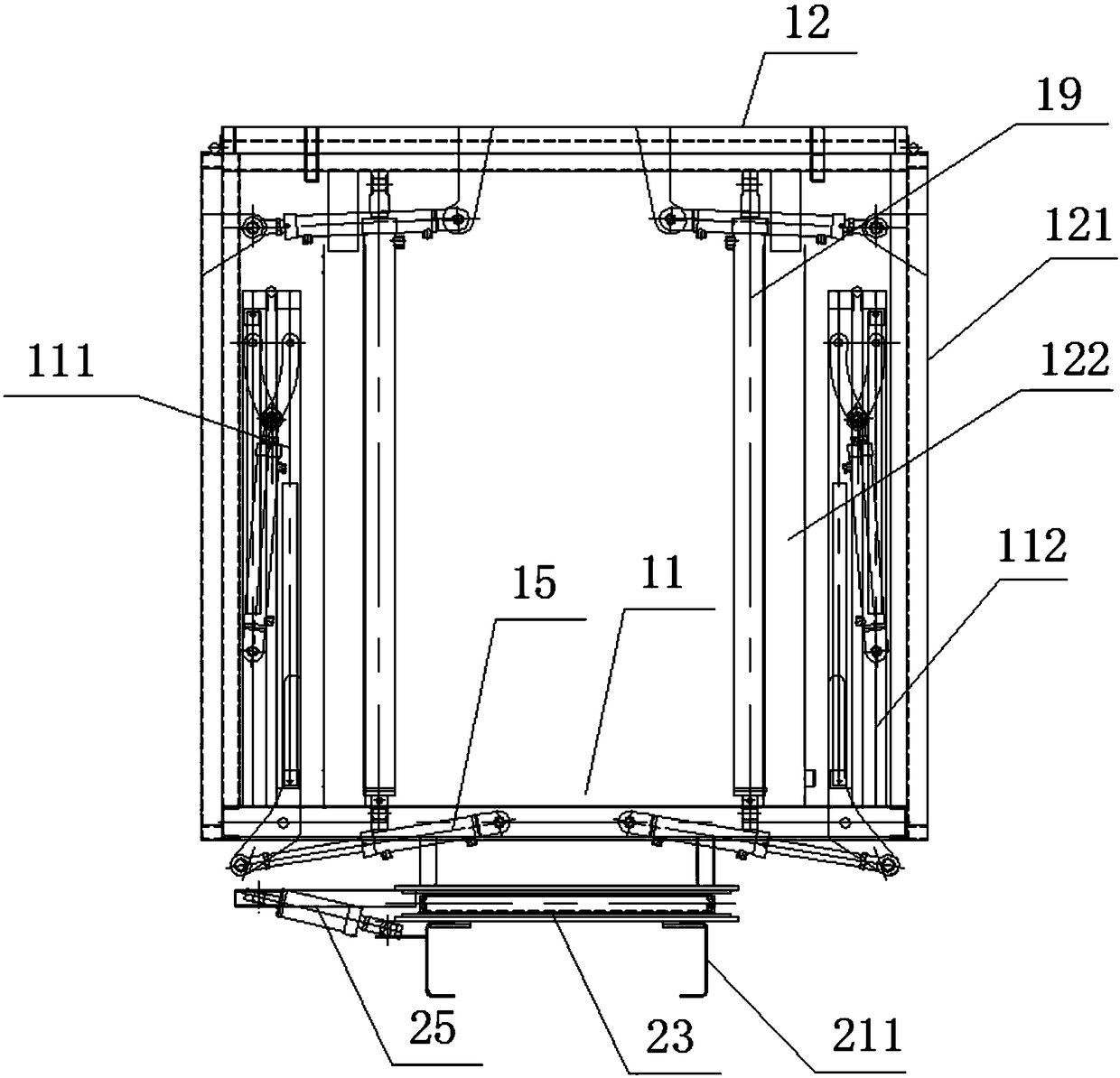

[0045] like figure 1 , figure 2 , image 3 As shown, a single-layer rotary stage vehicle includes a headstock, a main frame 21, and a rotating frame 22, and the headstock drives the main frame 21 to move. The rotating frame 22 is rotatably fixed on the main frame 21 through the turntable bearing 23 and moves longitudinally along the main frame 21 .

[0046] like Figure 15 , Figure 16 , Figure 17 , Figure 18As shown, the main frame 21 includes two parallel longitudinal beams 211 and a cross beam 212 connecting the two longitudinal beams 211 . Because when the compartment rotates, the distance between the center of rotation and the corner of the compartment is greater than the vertical distance between the center of rotation and the front of the car. Therefore, in order to avoid collisions between the corners of the car and the front of the car during the rotation. The present invention is also fixed with two sliders 231 at the bottom of the turntable bearing 23 . ...

Embodiment 2

[0069] Figure 4 , Figure 5 , Figure 6 Shown, a kind of double-deck stage car, can be set to the stage of rotation, also can be designed as non-rotating, present embodiment provides the non-rotating double-deck stage car. That is, on the basis of Embodiment 1, an equipment compartment 10 is added, and the equipment compartment 10 is in the compartment. The specific structure is:

[0070] The two side walls 101 of the equipment compartment 10 are hinged to the top wall 102 respectively, and are respectively driven and unfolded by the third driving mechanism 18 to form a platform coplanar with the top wall 102 of the equipment compartment 10 .

[0071] Such as Figure 12 As shown, LED display screens 103 can also be installed on both sides of the equipment compartment 10 . If it is larger than the side wall of the equipment compartment 10, the display screen 103 can be designed as a main screen 1031 and two side screens 1032. The two side screens 1032 are hinged on both s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap