Pin location testing mechanism

A testing mechanism and positioning mechanism technology, which is applied in circuit breaker testing, electrical measurement, and measuring devices, etc., can solve the problems of easy to miss inspections, high subjective arbitrariness of judgment standards, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

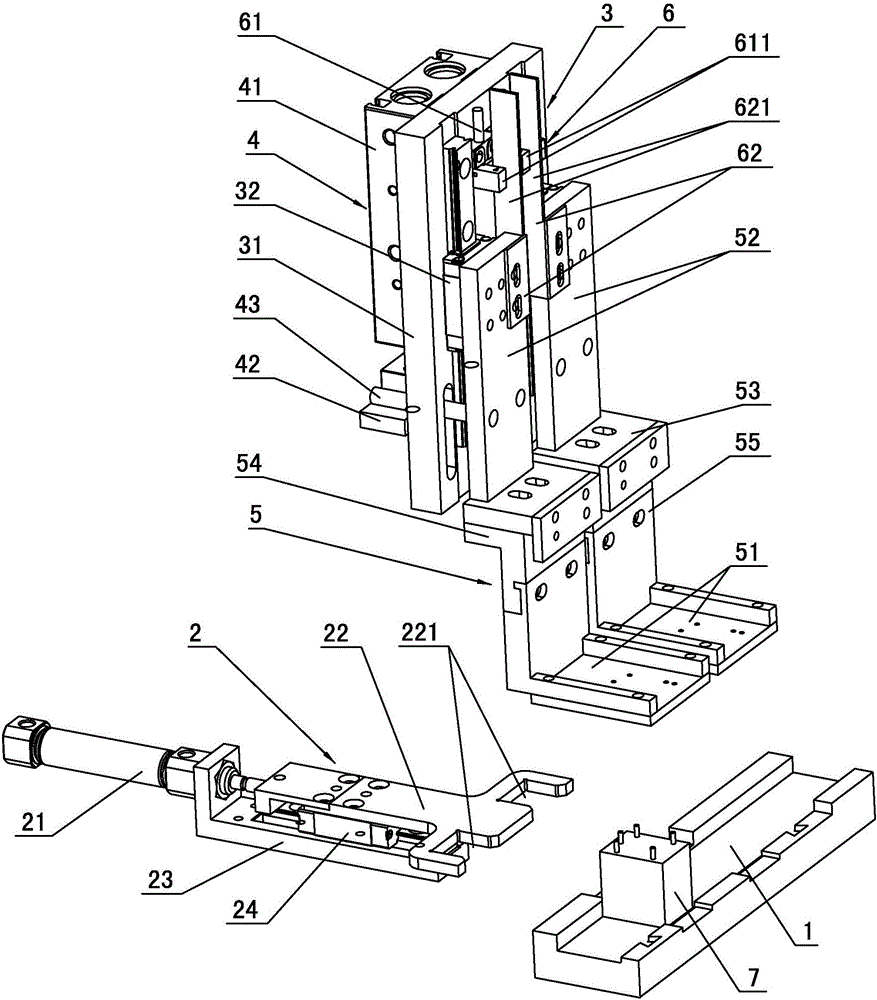

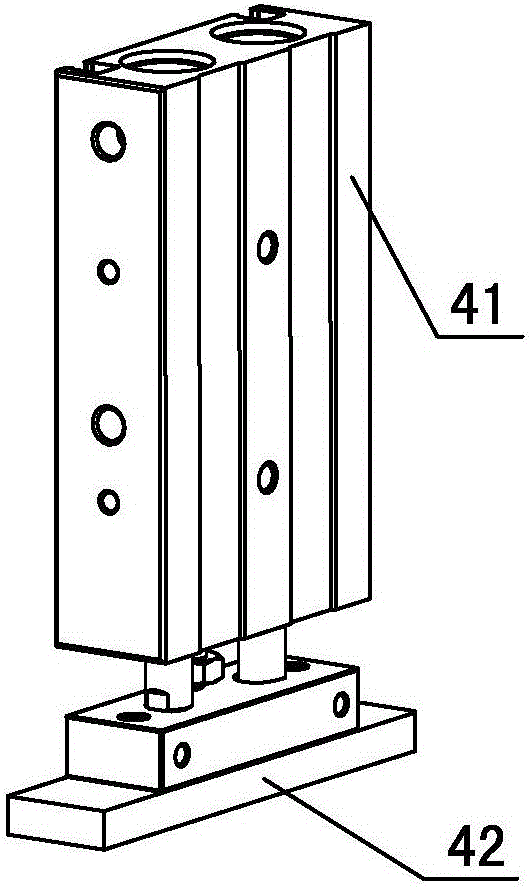

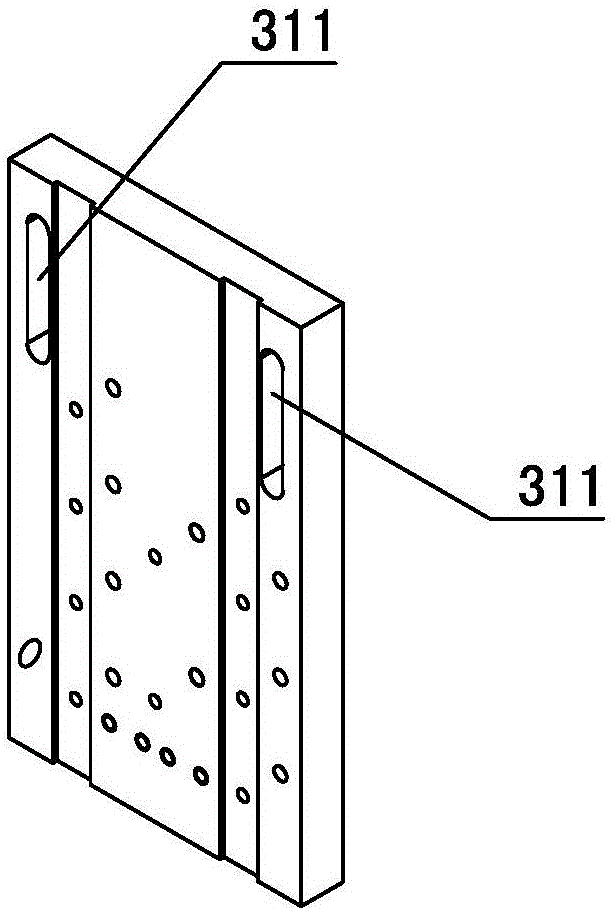

[0017] As shown in the figure, a foot test mechanism includes a test platform 1, a positioning mechanism 2 for fixing products, a guide mechanism 3, a driving component 4 and a foot template part 5 arranged above the test platform 1, the foot position The model part 5, the guide mechanism 3 and the drive part 4 have a matching structure that enables the foot position model part 5 to reciprocate perpendicular to the test platform 1 under the drive of the drive part 4 and the guidance of the guide mechanism 3. The guide mechanism 3 Including the guide main board 31 and two first linear guide rails 32 fixedly installed on one side of the guide main board 31, the foot template part 5 is fixedly installed on the slide block of the first linear guide rail 32, and the driving part 4 includes a vertical The driving cylinder 41 and the pulling block 42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com