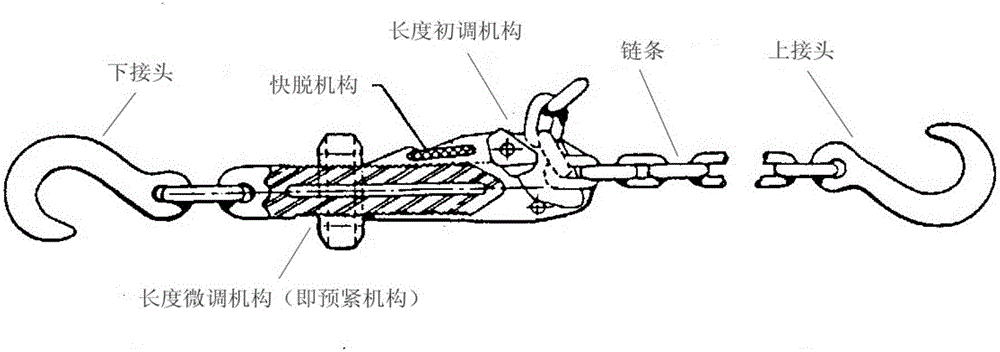

A line-driving Fast-mooring Regulator

A line-driven and adjuster technology, applied in the field of type-line-driven fast mooring adjusters, can solve the problems of heavy rigging, high labor intensity, and many personnel, so as to reduce the operating force, optimize the design, and reduce the The effect of the device's own weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

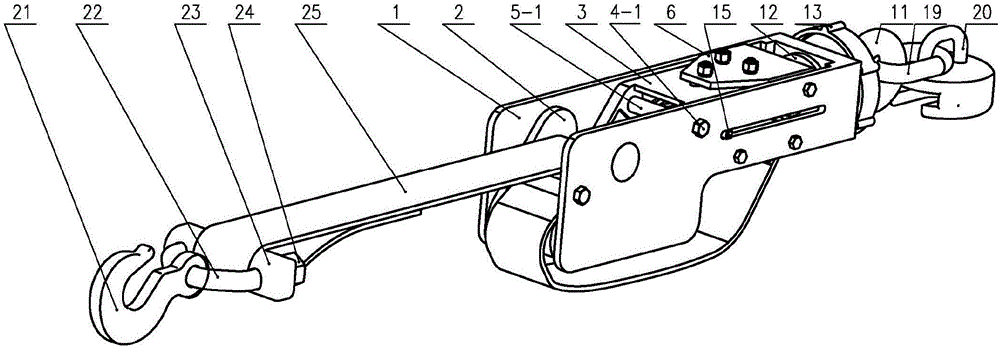

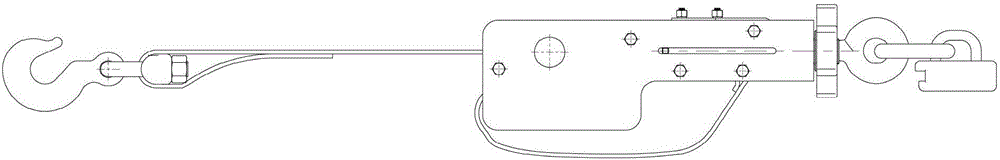

[0029] Do further explanation below in conjunction with accompanying drawing:

[0030] as attached Figure 2-7 As shown, a type-line-driven fast mooring regulator of the present invention includes a bearing frame 1, a rotating self-locking buckle 2, a quick-release pull lever 3, a quick-release buckle 6, a buckle screw 7, a return spring 10, Fine-tuning screw rod 11, fine-tuning nut 12, fine-tuning handle 13; In addition, it also includes connecting components at both ends, the rear-end connecting component includes hook 21, U-shaped connecting ring 22 and U-shaped ring mounting seat 23, and the front-end connecting component includes chain ring 19. Withhold 20.

[0031] The bearing frame 1 is composed of the front panel of the frame, the left panel of the frame, and the right panel of the frame. There are trunnion installation holes at the rear of the left panel of the frame and the right panel of the frame. In the shaft mounting hole, the swivel lock 2 consists of two side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com