Rotation type cover lock and washing machine with rotation type cover lock

A washing machine and rotary type technology, applied in the field of locking devices and washing machine locking devices, can solve the problems of destroying the surface flatness of the upper cover and the control panel seat, complex structure, etc., and achieve the effects of reliable function, beautiful appearance and reliable cooperation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

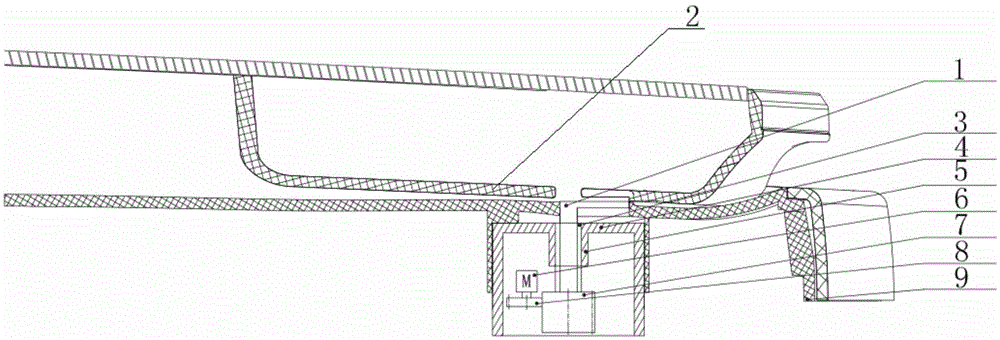

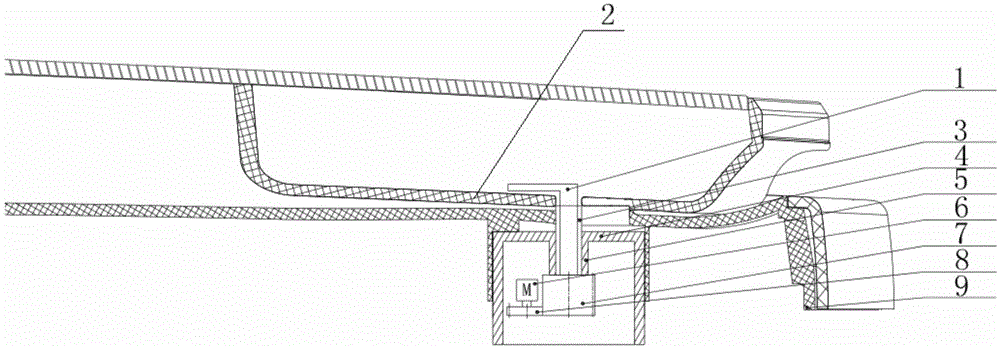

[0026] A rotary cover lock of the present invention includes a driving device, a lock handle, and a lock tongue. The lock tongue and the lock handle are integrally arranged. The lock tongue and the lock handle are L-shaped. The tongue rotates and moves up and down, and also includes an anti-off plate that cooperates with the dead bolt. After the lock handle is rotated in place, the dead bolt and the anti-off plate are locked together.

[0027] The lock handle is a screw rod with external threads, the lock handle cooperates with the nut, the nut is fixedly installed on the support frame, the driving device is fixedly installed on the support frame and drives the lock handle to rotate in the nut, and the dead bolt is arranged on the top of the lock handle.

[0028] A first gear is arranged on the lock handle, which meshes with a second gear arranged on the driving device.

[0029] The bottom of the lock handle is provided with a first gear, the driving device is a motor, and the...

Embodiment 2

[0033] A washing machine provided with a rotary cover lock in this embodiment is equipped with the rotary cover lock in the first embodiment.

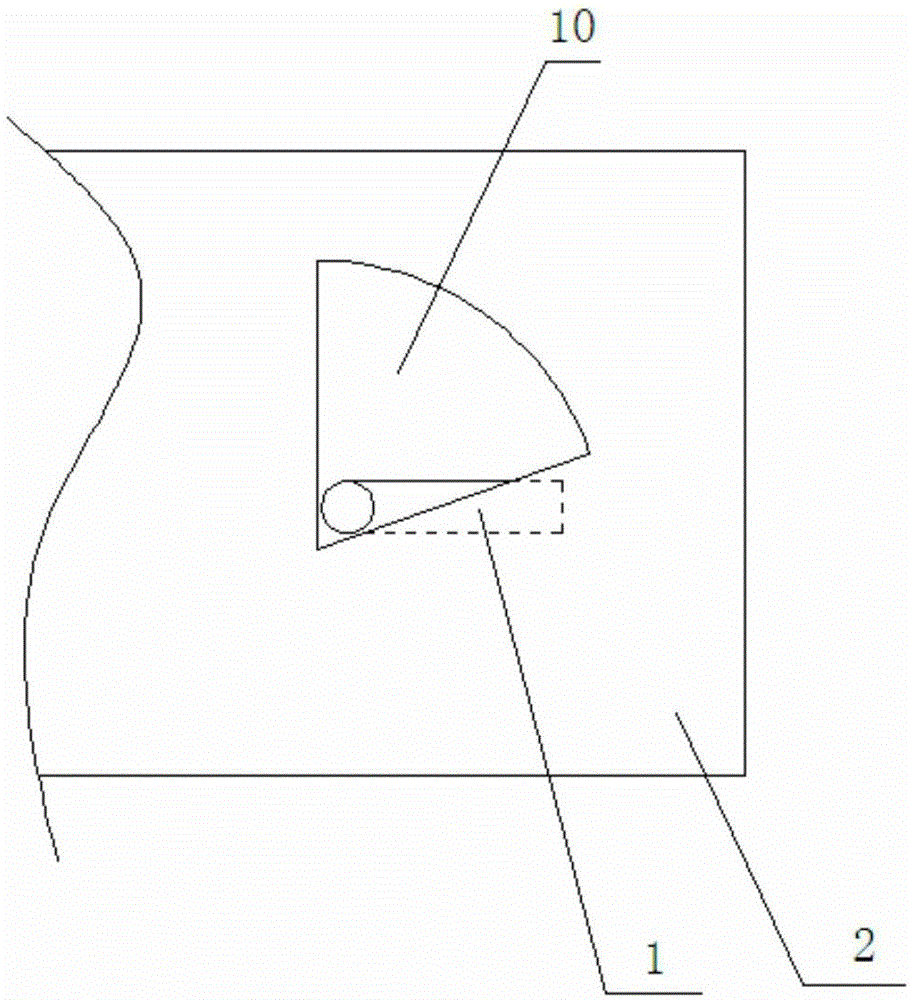

[0034] Such as Figure 1-4 As shown, the washing machine includes a washing machine control panel seat and a washing machine upper cover. A driving device for a rotary cover lock, a lock handle, a lock tongue, a nut, a gear and a support frame are installed in the washing machine control panel seat. The lock tongue and the lock handle are integrated , the lock tongue and the lock handle are L-shaped, and the driving device drives the lock handle to rotate along its own central axis. The bottom of the upper cover of the washing machine is provided with a fan-shaped vacancy for the lock tongue to enter and an anti-off plate. In this embodiment, at the bottom of the upper cover The fan-shaped vacancy is set so that the bottom of the upper cover with the fan-shaped vacancy acts as an anti-off plate.

[0035] When the lock handle is rotati...

Embodiment 3

[0042] The difference between this embodiment and Embodiment 2 is that in order to make the lock handle more stable when rotating, two upper and lower nuts are coaxially arranged on the support frame, and there is an interval between the two nuts, and the lock handle cooperates with the nut. A first gear is arranged at the lock handle between the two nuts, the driving device is a motor, and the second gear arranged on the output shaft of the motor meshes with the first gear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com