An independent reset device for the main mold of a top heading pipe bending machine and its application method

A technology of reset device and pipe bending machine, which is applied in the direction of positioning device, feeding device, storage device, etc., to achieve high processing efficiency, simple process, and avoid frictional interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

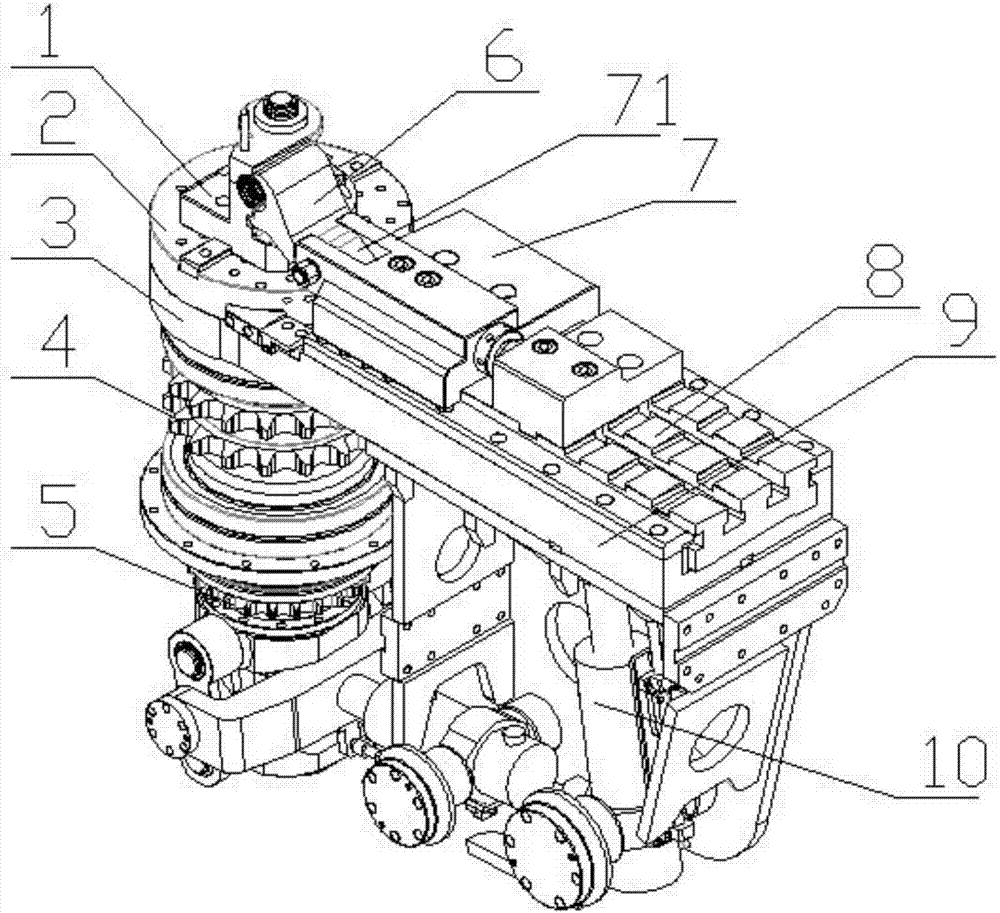

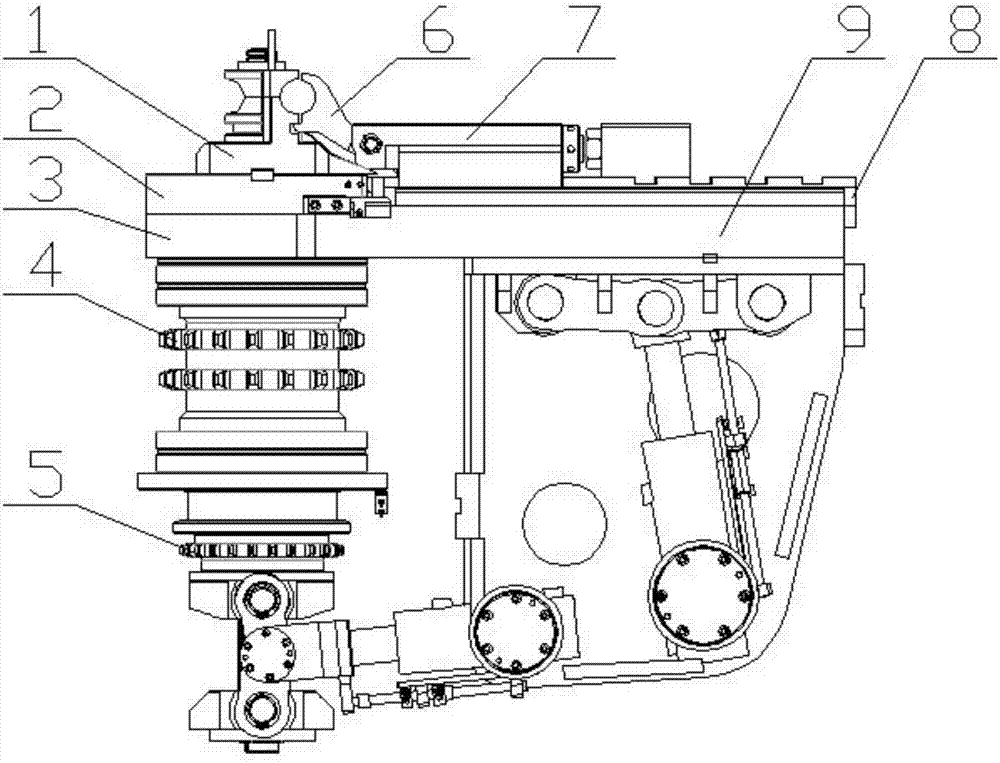

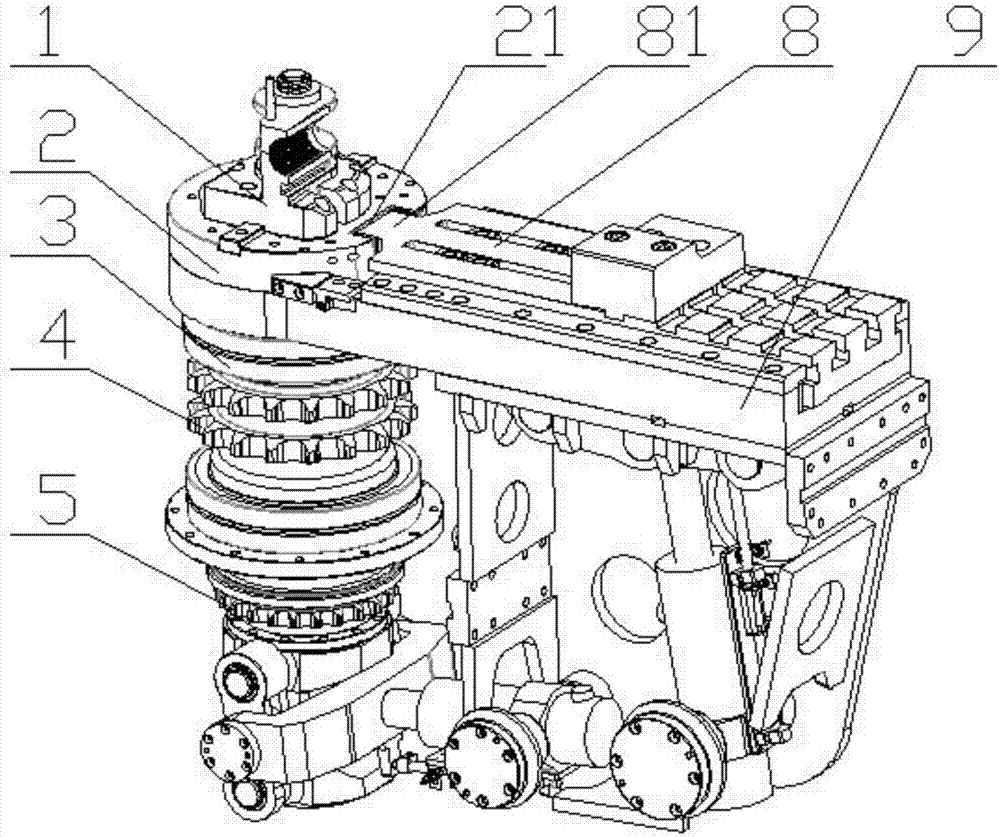

[0040] Such as figure 1 , figure 2 and image 3 As shown, an independent reset device for the main mold of a top heading pipe bending machine, including a main mold 1, a main mold base 2, a main mold bracket 3, a slider base 9 and a slider drive 10, and the main mold 1 is fixed on the main mold base 2; the side on the main mold 1 is provided with a slope block 11; the position corresponding to the slope block 11 on the main mold base 2 is provided with a main mold linkage groove 21; the main mold base 2 is rotatably arranged on the main mold support 3, Such as Figure 4 As shown, specifically: the main mold support 3 is a hollow structure; the upper end of the main mold base 2 is connected with the upper end face bearing of the main mold support 3, and the lower end passes through the main mold support 3 and is fixedly connected with the main mold base gear 5, and the main mold base gear 5 It is connected with the main mold bracket 3 through bearings; the outer wall of the...

Embodiment 2

[0045] An independent reset device for the main mold of a top heading pipe bending machine, which is basically the same as that of Embodiment 1, except that a track is set on the upper surface of the slider 8, and the clamping base 7 is set on the track and fixed by a set bolt; The upper surface of the block 8 is provided with a T-shaped groove, and the T-shaped groove is provided with a clamping mold positioning seat, which is fixed by a set bolt; the clamping mold base 7 is provided with a clamping mold fine-tuning rod, and one end of the clamping mold fine-adjusting rod is connected with the end surface of the clamping mold base. Threaded connection, the other end is in contact with the positioning seat of the clamping mold; the clamping mold fine-tuning nut is arranged on the clamping mold fine-tuning rod.

[0046] Compared with Embodiment 1, the stroke adjustment function of the clamping die 6 is added in this embodiment. When the diameter of the pipe to be processed chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com