Novel length measuring system

A new type of length measurement technology, applied in the field of length measurement system, can solve the problems of inaccurate length measurement, large error, easy sliding of length measuring wheel and strip, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

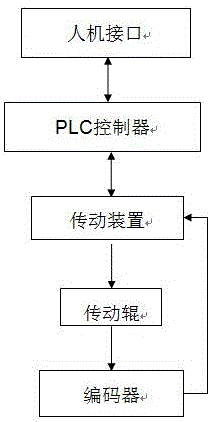

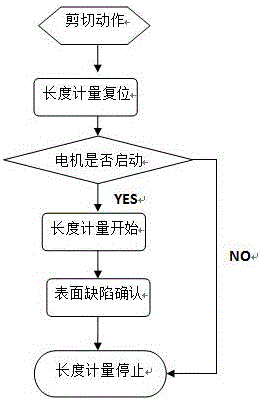

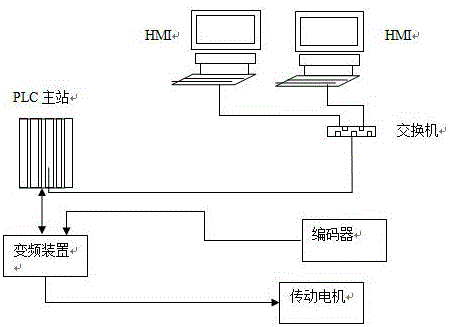

[0014] Example 1: see Figure 1-Figure 3 , a new type of length measurement system, the length measurement system includes an encoder detection unit, a transmission unit, a PLC control unit and a human-machine interface HMI, the encoder detection unit realizes the measurement of the transmission length of the measured object strip, the described The transmission unit is arranged between the PLC control unit and the man-machine interface HMI. The encoder detection unit is mainly composed of an encoder, which is installed on the shaft end of the main motor and rotates synchronously with the main motor. Normally, the strip is in close contact with the transmission roller, and the linear velocity of the strip at the contact point is equal to that of the transmission roller, and the length of the strip can be calculated by calculating the distance that the roller has turned; the PLC control unit Including the PLC master station, the PLC realizes functions such as length calculatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com