High efficiency full-automatic framing machine for solar cell module

A solar cell, fully automatic technology, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the abnormality of device operation continuity, synchronization, hysteresis, reliability, affecting the packaging quality of solar cell modules, and the sealing of module frames. It can reduce the waiting and avoidance time, avoid visual differences, and ensure the quality of packaging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

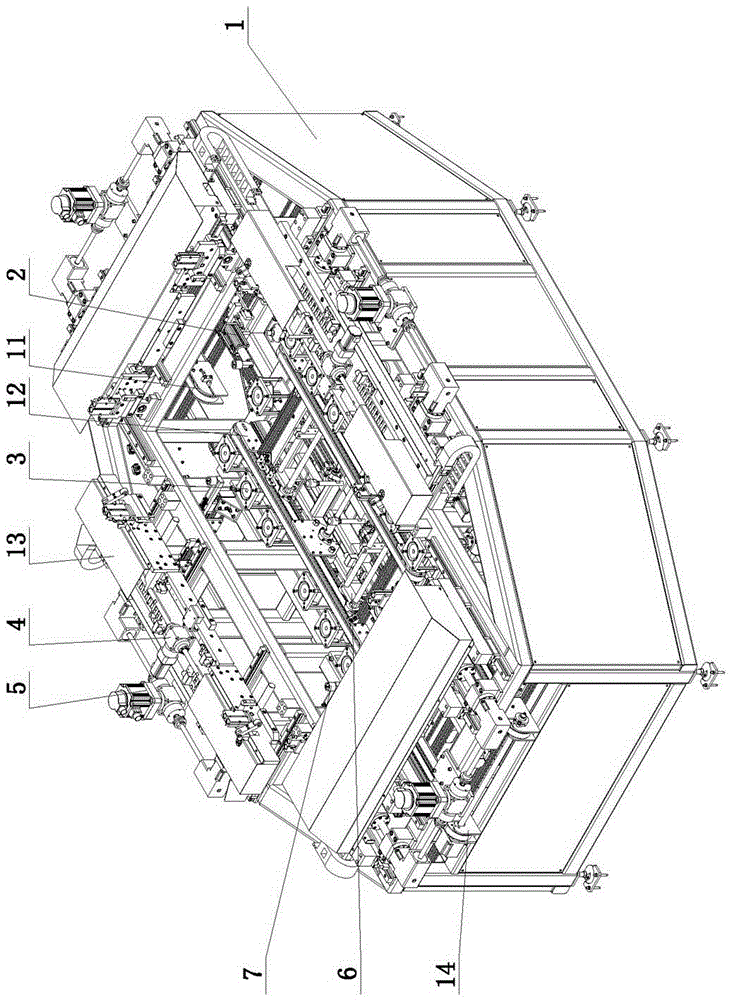

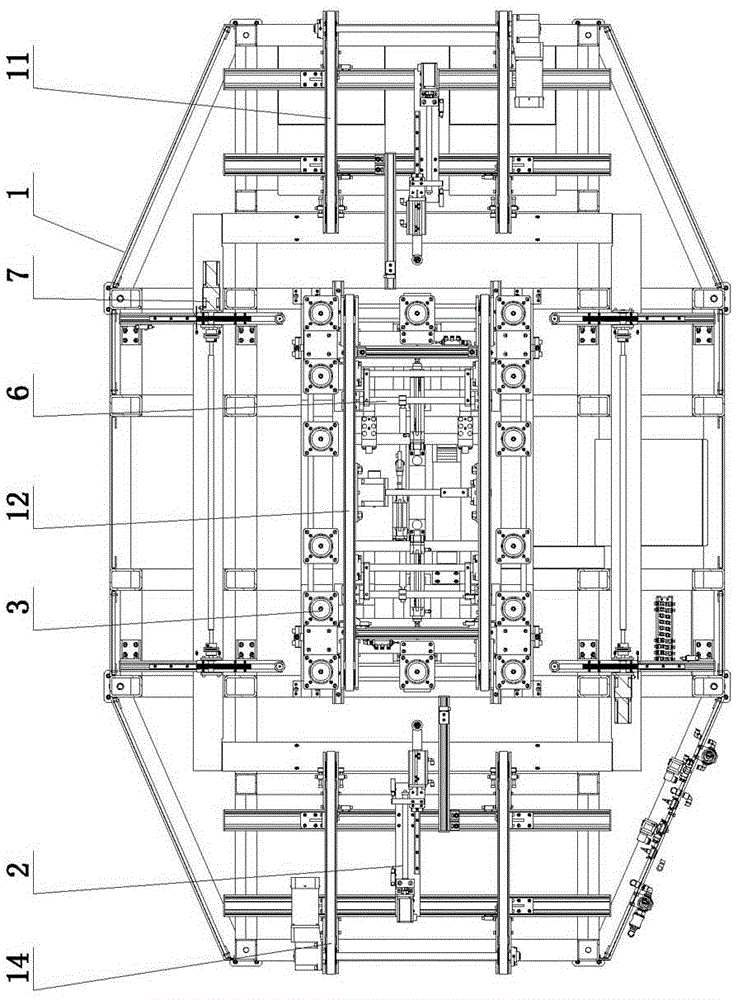

[0033] The present invention includes a fuselage 1, which is characterized in that: the two ends of the fuselage 1 are respectively provided with a feed transmission device 14 and a discharge transmission device 11, and the middle part of the fuselage 1 is provided with an intermediate transmission device 12 through a lifting device 6; the fuselage 1 A component positioning device 3 is provided at a position corresponding to the intermediate transmission device 12 , and frame closing devices 5 are provided on four sides of the component positioning device 3 .

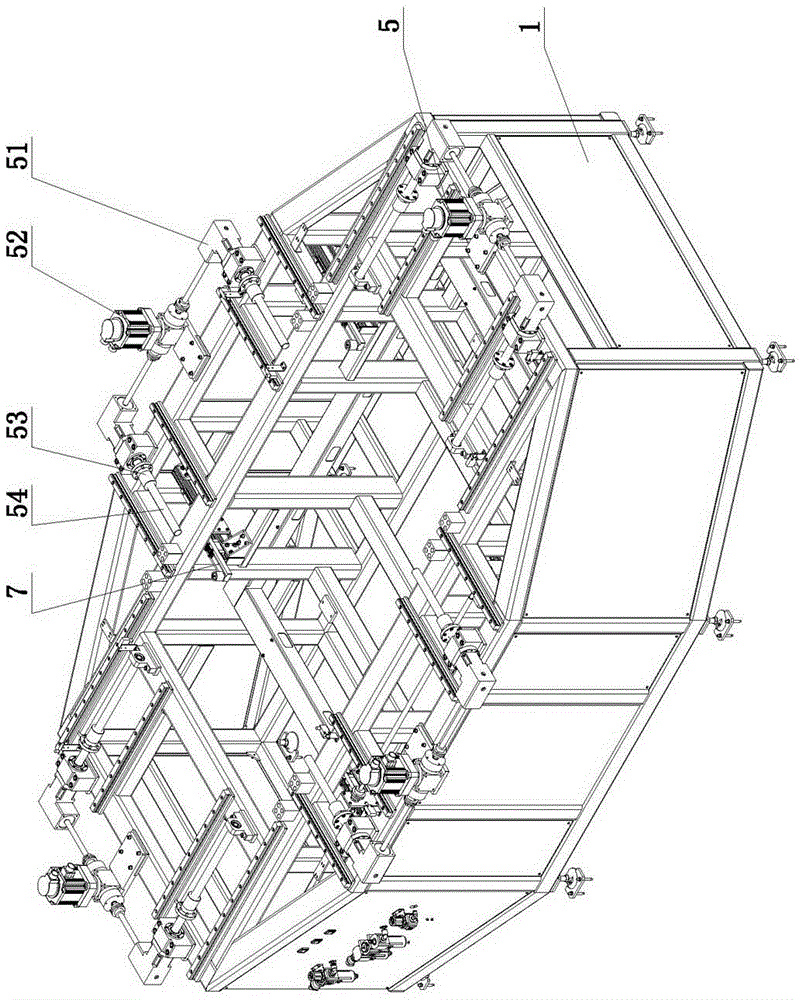

[0034] The lifting device 6 includes a lifting cylinder 62 arranged on the fuselage 1, the piston rod of the lifting cylinder 62 is connected with a transverse connecting rod 63, the two ends of the transverse connecting rod 63 are hingedly provided with a lever 61, and the two levers 61 The ends of each are connected with a rotating rod 64, and the two rotating rods 64 are connected with a swing frame 65, and the ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com