An automatic sharpening device and its control system and control method

A technology of automatic knife sharpening and driving device, which is applied in the direction of grinding automatic control device, other manufacturing equipment/tools, manufacturing tools, etc. The effect of convenient and precise control of knife sharpening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

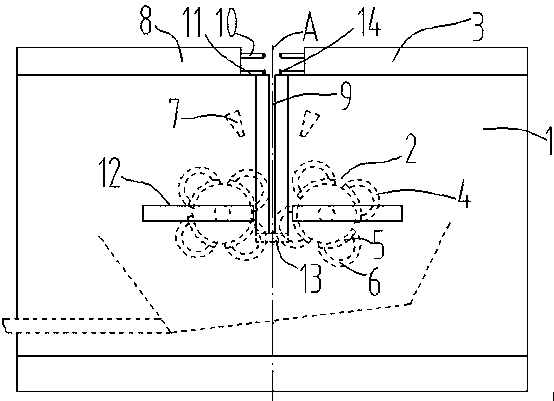

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] like figure 1 The automatic sharpening device shown includes a grinding body 1 and a grinding tool 2. The top of the grinding body 1 is provided with a strip-shaped opening, and the knife is put into the knife-sharpening device through the strip-shaped opening, and the lower part of the strip-shaped opening is along the opening The centerline A of the center line A is symmetrically provided with two grinding tools 2, and the grinding tools 2 are rotated to grind the tool. The upper part of the bar is provided with a tool clamping device 3 for clamping the tool. Specifically in 1, the rotating rod is connected with a driving device, and the driving device of the rotating rod is preferably a waterproof motor; a side that is vertically connected with the top strip opening on the grinding body 1 is provided with a knife gap 9 for placing a cutter, and a knife gap ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com