Characterization of Interface Structure in Plastic Bonded Explosives Based on Gas Permeation Method

A technology of gas permeation and interface structure, which is applied in permeability/surface area analysis, material analysis, suspension and porous material analysis, etc. It can solve problems such as lack of technology, and achieve the effect of simple and easy characterization technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

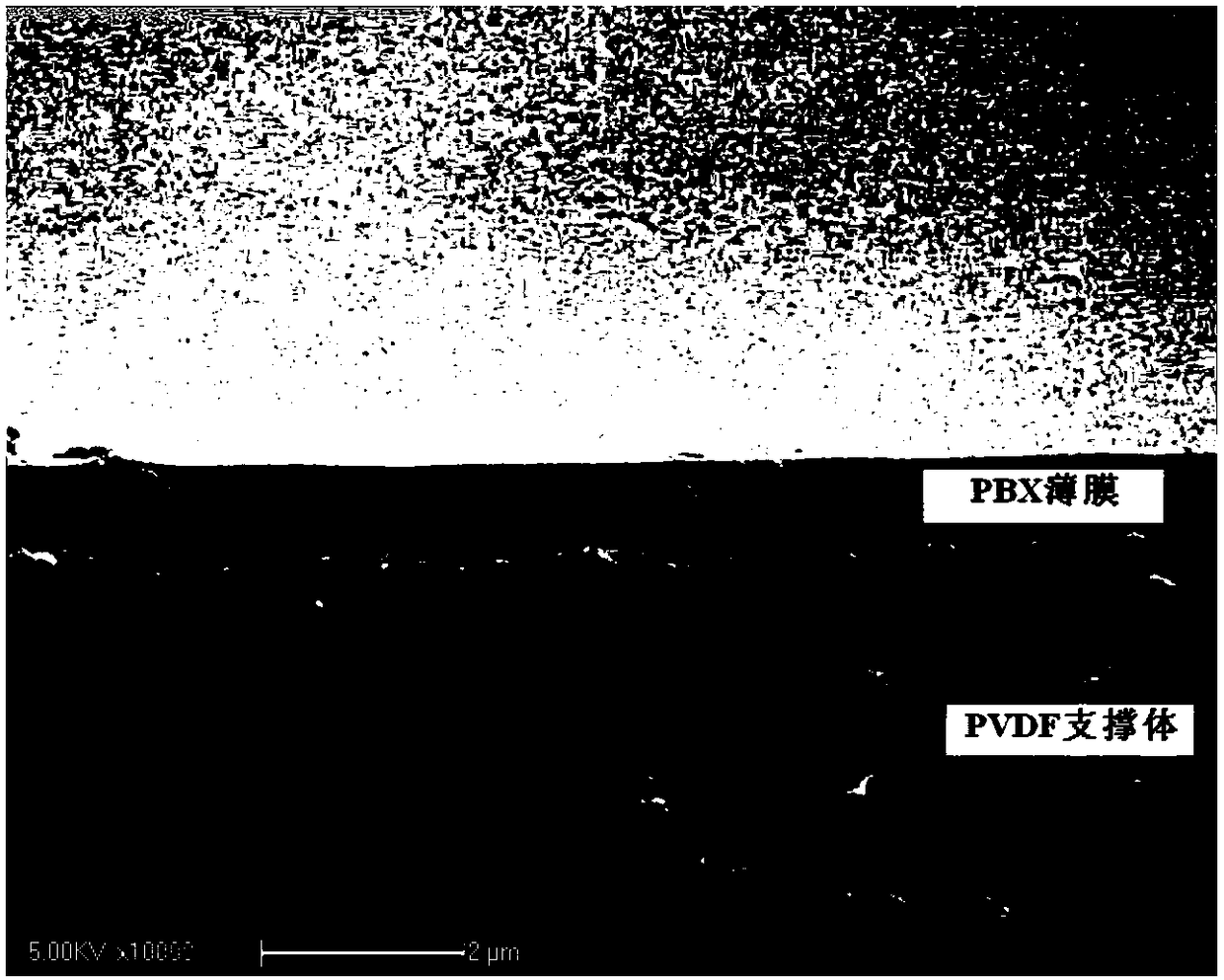

[0035] Add 4g of F2311 rubber into 96g of ethyl acetate, and stir at 40°C for 10 hours to obtain an ethyl acetate solution with a content of 4wt% F2311. Add HMX with an average particle size of 1.36 μm into the ethyl acetate solution, stir for 10 minutes, and ultrasonically disperse for 30 minutes to obtain HMX suspensions with contents of 0, 0.04, 0.2, 0.32, and 0.4 wt%, respectively. The HMX suspensions with contents of 0, 0.04, 0.2, 0.32 and 0.4wt% were respectively coated on the surface of polyvinylidene fluoride (PVDF) porous ultrafiltration membrane by scraping method, and the wet coating thickness was 120 μm. The surface pore size of PVDF ultrafiltration membrane is 15nm. The solvent was evaporated at 30°C to prepare a PBX film. The thickness of the PBX film is 1.1 μm as measured by the electron microscope, as attached figure 1 shown.

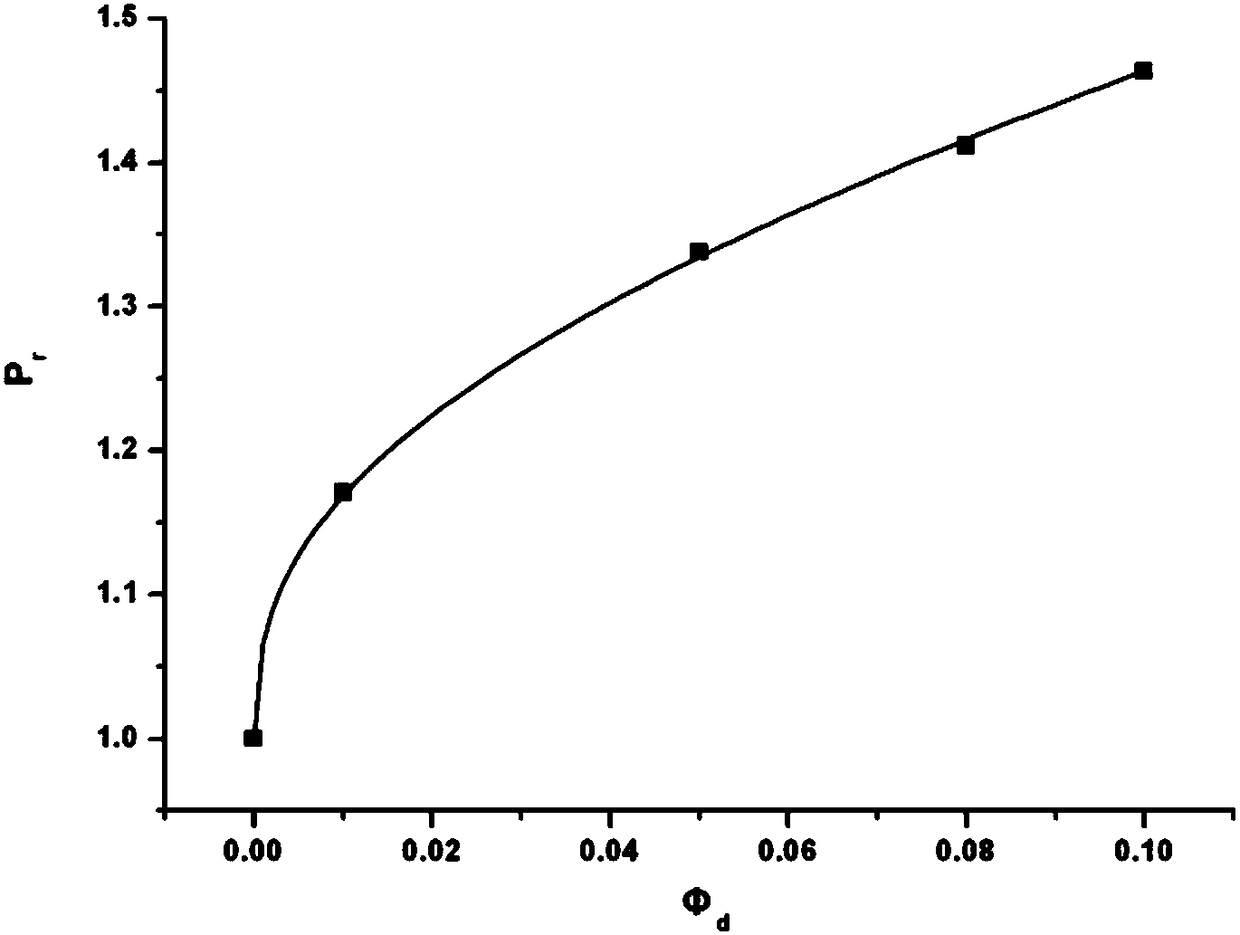

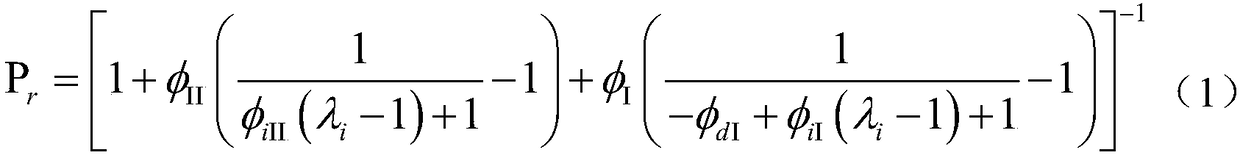

[0036] The volume fractions of HMX in PBX films were 0, 1, 5, 8, and 10%, respectively. to N 2 Molecules are probes, and the gas p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com