Device and method for testing circumferential tensile strength of thin-wall pipe material

A thin-walled pipe, tensile strength technology, applied in the direction of applying stable tension/pressure to test material strength, measuring device, strength characteristics, etc. problems, to avoid sample defects and directly test the results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The device for testing the hoop tensile strength of thin-walled pipes according to the present invention will be described in detail below in conjunction with the accompanying drawings and examples:

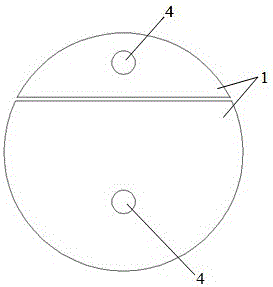

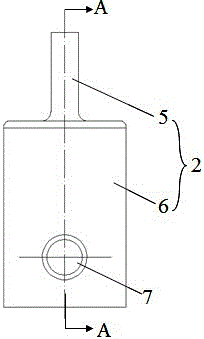

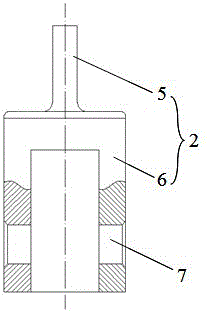

[0034] Such as Figure 1~4 As shown, a device for testing the hoop tensile strength of thin-walled pipes includes a disc-shaped holder 1, two connectors 2 and a fixing pin 3 for fixing the holder 1 and the connector 2; the holder 1 Divided into two semicircles of unequal size, each semicircle is formed with a fixing hole 4; the connector 2 is composed of a connecting handle 5 and a "ㄇ" type connector 6; the connecting handle 5 and the connector 6 are cross beams fixed at the center; pin holes 7 are formed on both side walls of the connector 6.

[0035] The distance from the center of the fixing holes 4 on different semicircles to the center of the holder 1 is equal, and the axis of the pin hole 7 is perpendicular to the axis of the connecting handle 5 .

[0036] The axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com