Negative ion mulberry silk floss production method

A production method and technology of negative ions, applied in silk fiber production, cocoon cleaning/classification, chemical post-processing of fibers, etc., can solve the problems of long-lasting efficacy and low air ion solubility, and achieve long-lasting efficacy and low labor intensity. , the effect of high ionic solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

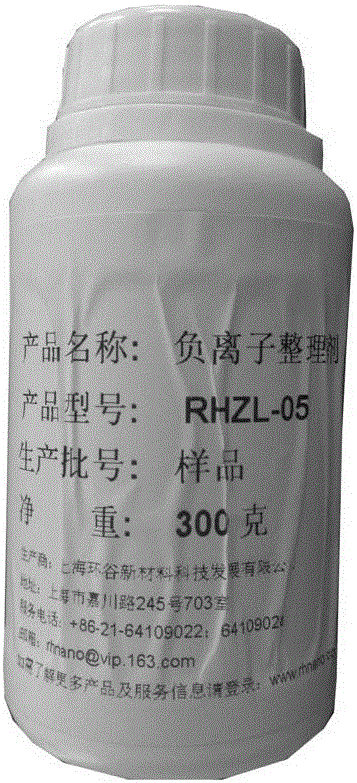

Image

Examples

Embodiment 1

[0046] The following steps can be used to produce negative ion mulberry silk cotton:

[0047] (1) Cocoon removal of impurities: the use of silkworm cocoon removal machines combined with manual selection and removal of impurities makes the impurity content of the produced silkworm cocoons far lower than the national standard;

[0048] (2) Squeezing: Squeezing the artificially selected cocoons with a slicing machine to obtain silk flakes;

[0049] (3) Boil the cotton: wash and dehydrate the silk cotton sheet with clean water, and then use a sodium hydroxide solution with a temperature of 60-70°C and a concentration of 3-5% by weight to boil the cotton for 2-3 hours. Minutes, add negative ion finishing agent in boiling cotton solution; The addition of negative ion finishing agent is 3% of the volume of boiling cotton solution;

[0050] (4) Dehydration cleaning: After the cotton is boiled, first dehydrate the silk cotton sheet, then wash and dehydrate twice, and finally put it in...

Embodiment 2

[0059] The following steps can be used to produce negative ion mulberry silk cotton:

[0060] (1) Cocoon removal of impurities: the use of silkworm cocoon removal machines combined with manual selection and removal of impurities makes the impurity content of the produced silkworm cocoons far lower than the national standard;

[0061] (2) Squeezing: Squeezing the artificially selected cocoons with a slicing machine to obtain silk flakes;

[0062] (3) Boil the cotton: wash and dehydrate the silk cotton sheet with clean water, and then use a sodium hydroxide solution with a temperature of 60-70°C and a concentration of 3-5% by weight to boil the cotton for 2-3 hours. Minutes, add negative ion finishing agent in boiling cotton solution; The addition of negative ion finishing agent is 3% of the volume of boiling cotton solution;

[0063] (4) Dehydration cleaning: After the cotton is boiled, first dehydrate the silk cotton sheet, then wash and dehydrate twice, and finally put it in...

Embodiment 3

[0072] The following steps can be used to produce negative ion mulberry silk cotton:

[0073] (1) Cocoon removal of impurities: the use of silkworm cocoon removal machines combined with manual selection and removal of impurities makes the impurity content of the produced silkworm cocoons far lower than the national standard;

[0074] (2) Squeezing: Squeezing the artificially selected cocoons with a slicing machine to obtain silk flakes;

[0075] (3) Boil the cotton: wash and dehydrate the silk cotton sheet with clean water, and then use a sodium hydroxide solution with a temperature of 60-70°C and a concentration of 3-5% by weight to boil the cotton for 2-3 hours. Minutes, add negative ion finishing agent in boiling cotton solution; The addition of negative ion finishing agent is 3% of the volume of boiling cotton solution;

[0076] (4) Dehydration cleaning: After the cotton is boiled, first dehydrate the silk cotton sheet, then wash and dehydrate twice, and finally put it in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com