Quark based fat mixture comprising plant oil and a process for producing it

A technology of fat mixture and edible vegetable oil, which is applied in the direction of edible oil/fat, edible oil/fat phase, edible oil/fat composition, etc., and can solve problems such as rough texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

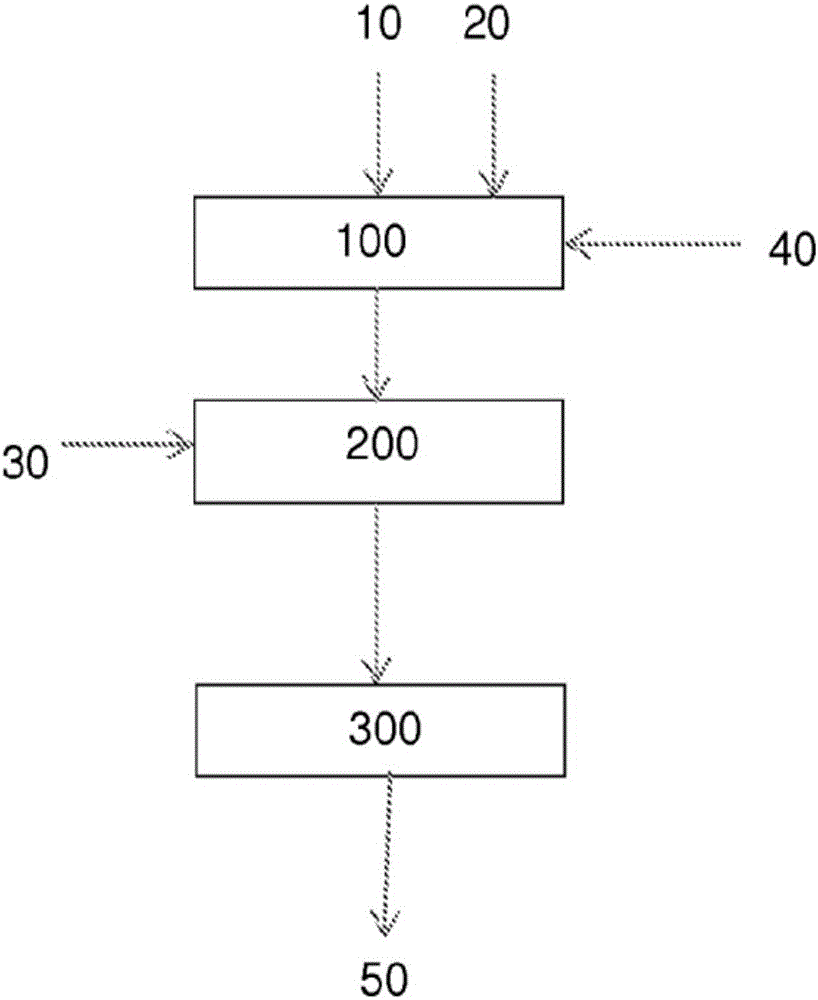

Image

Examples

Embodiment 1

[0121] Manufacturing of Quark Cheese

[0122] 1000 L of the solution, comprising milk raw material and having a protein content of 3.7 wt%, was pasteurized at a temperature of 87°C and homogenized for 7 minutes.

[0123] After pasteurization, the solution was cooled to a temperature of about 29° C., using a plate heat exchanger in the cooling.

[0124] Acidulant (starter culture) and lactase are added to the cooled solution. During a period of 15 hours to 20 hours, the pH of the acidification and lactose hydrolysis solution was lowered to a level of about 4.5 to provide a curd mixture. Then stir in the curd mixture.

[0125] The curd mixture was further processed into quark cheese as follows: the curd mixture was pasteurized on a plate heat exchanger at a temperature of 63°C. After heat pasteurization, the curd mixture was cooled to 43°C and sieved. Subsequently, the curd mixture was subjected to separation in which the quark cheese mass was separated from the solution by ...

Embodiment 2

[0127] Manufacture of acidified milk base

Embodiment 21

[0129] 40% by weight of skim milk and 60% by weight of ultrafiltered milk (ultrafiltered milk concentrate) were mixed. The mixture was then pasteurized at 85°C for 3-4 minutes. The milk base was cooled to 30° C., and 0.1 wt % of starter culture (YO MIX (Danisco Yogurt Strain)) was added. The blend was mixed for 10 minutes and fermented at 35-45°C for about 5.5-6 hours or until the pH was about 4.9. The acidified milk base was mixed and cooled to a temperature of 13°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com