A welding device for side plates of garbage truck fillers

A technology for welding devices and fillers, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems affecting the size consistency and stability of filler parts, the speed of side plate welding production, and the assembly accuracy of fillers and other problems, to achieve the effect of fast clamping, positioning and splicing, improving production efficiency and shortening the assembly speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

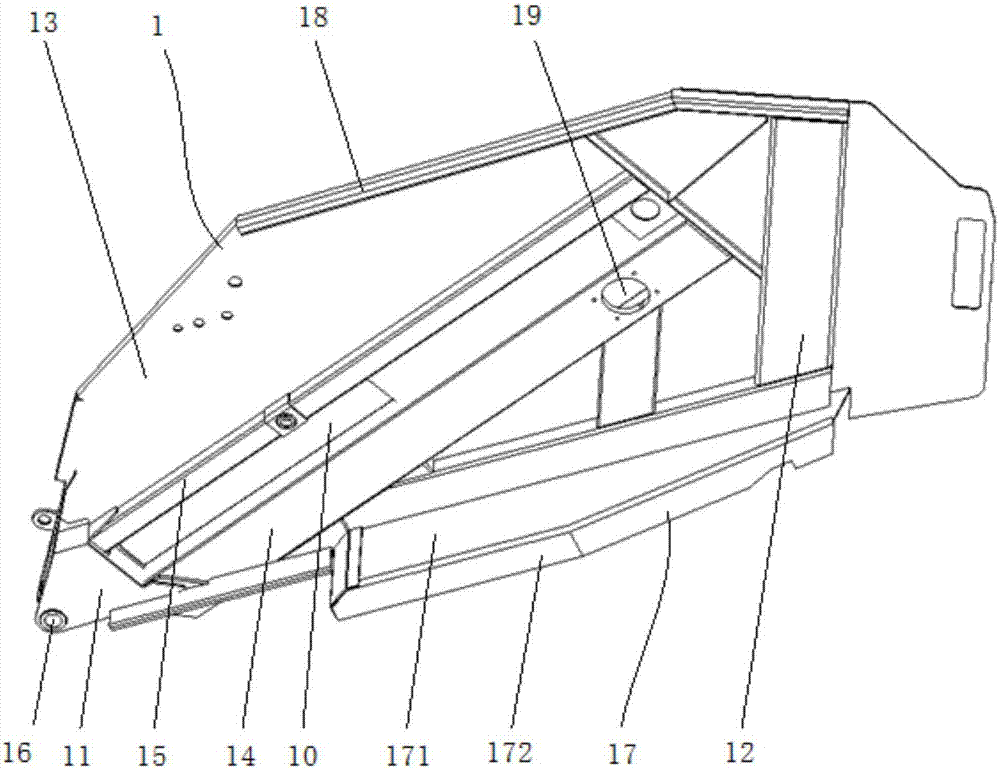

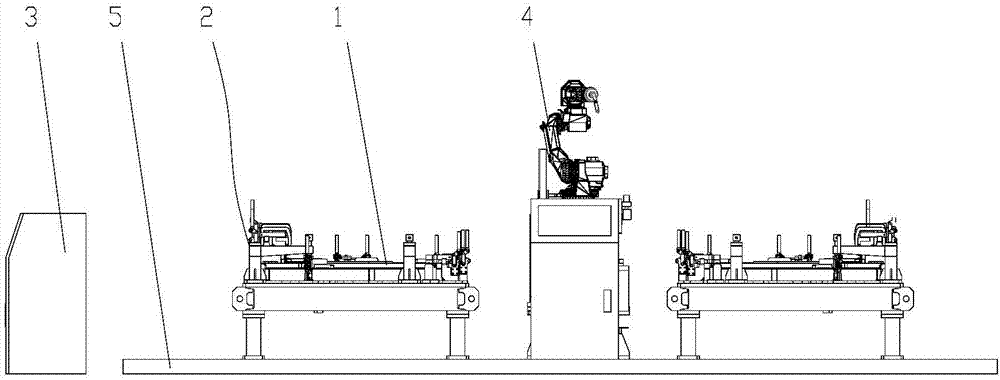

[0027] Such as Figure 1-8 As shown in one of them, a welding device for the side plate of a garbage truck filler, the side plate 1 of the filler includes a triangular support 11, a first side plate 12 and a second side plate arranged on both sides of the bottom edge of the support 11 The two side plates 13 and the pusher chute 14 and the reinforcing groove 15 that are arranged between the first side plate 12 and the second side plate 13 at intervals, the top corner of the support 11 is provided with a turning shaft hole 16, the first side The side of the plate 12 away from the second side plate 13 is provided with a base plate 17 perpendicular to the first side plate 12 for installing the overturning oil cylinder, and the other side of the second side plate 13 away from the first side plate 12 is provided with a base plate 17 for connecting activities. The cover plate guide rail 18 of the cover plate, the welding device includes at least one welding fixture 2, the welding fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com