Robot welding equipment for barbecue oven

A technology for robot welding and barbecue ovens, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as quality problems and high labor intensity, achieve rich welding functions, improve production efficiency, and facilitate adjustment of welding parameters Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

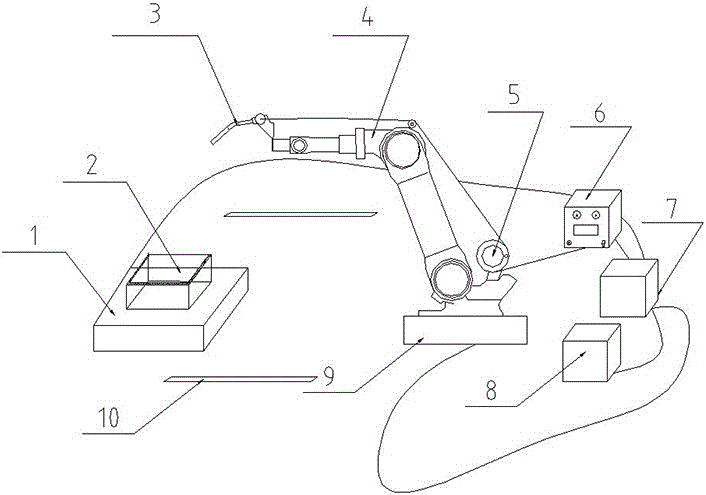

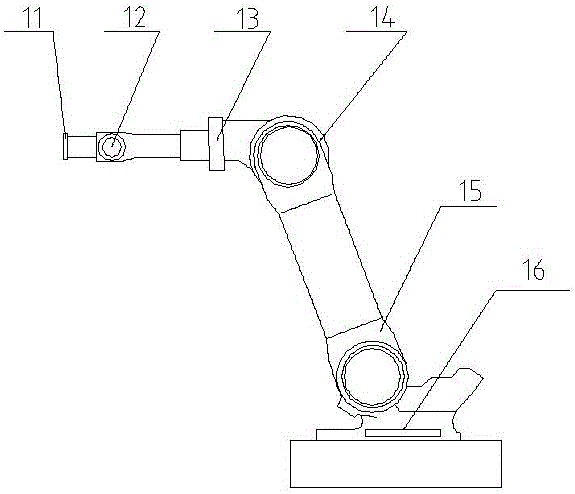

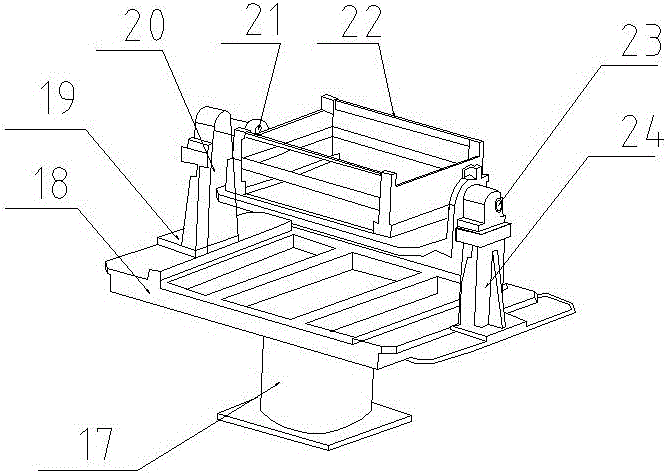

[0022] like figure 1 As shown, the present invention is a kind of barbecue oven robot welding equipment, including robot 4, PLC controller 7, video monitoring feedback system 8, safety protection device 10, welding equipment, rotary table 1 and teaching pendant, teaching pendant is in figure 1 Not shown in the figure, the PLC controller 7 is connected with the robot 4, the welding equipment, the rotary table 1, the safety protection device 10, the video monitoring feedback system 8 and the teaching pendant, so as to realize receiving feedback signals or sending control signals, showing The teaching device is transmitted to the actuator of the robot 4 through the programmed program. The barbecue oven 2 to be welded is clamped in the welding fixture. The mutual cooperation of platform 1 completes the welding of barbecue oven 2, wherein:

[0023] The PLC contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com