Substrate fixture

A fixed device and fixed position technology, applied in the direction of circuits, discharge tubes, electrical components, etc., can solve problems such as large-scale complex devices and substrate position deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

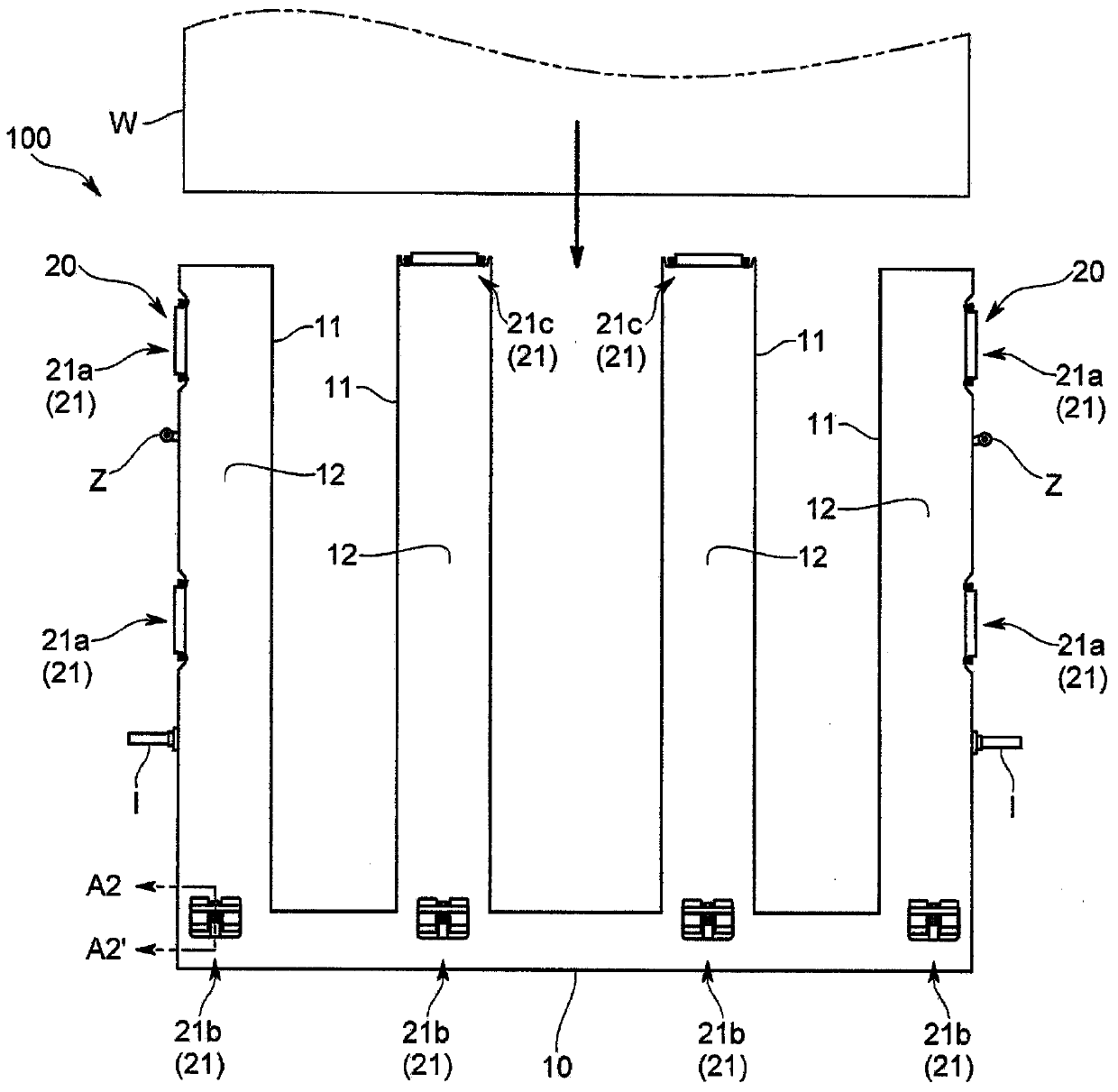

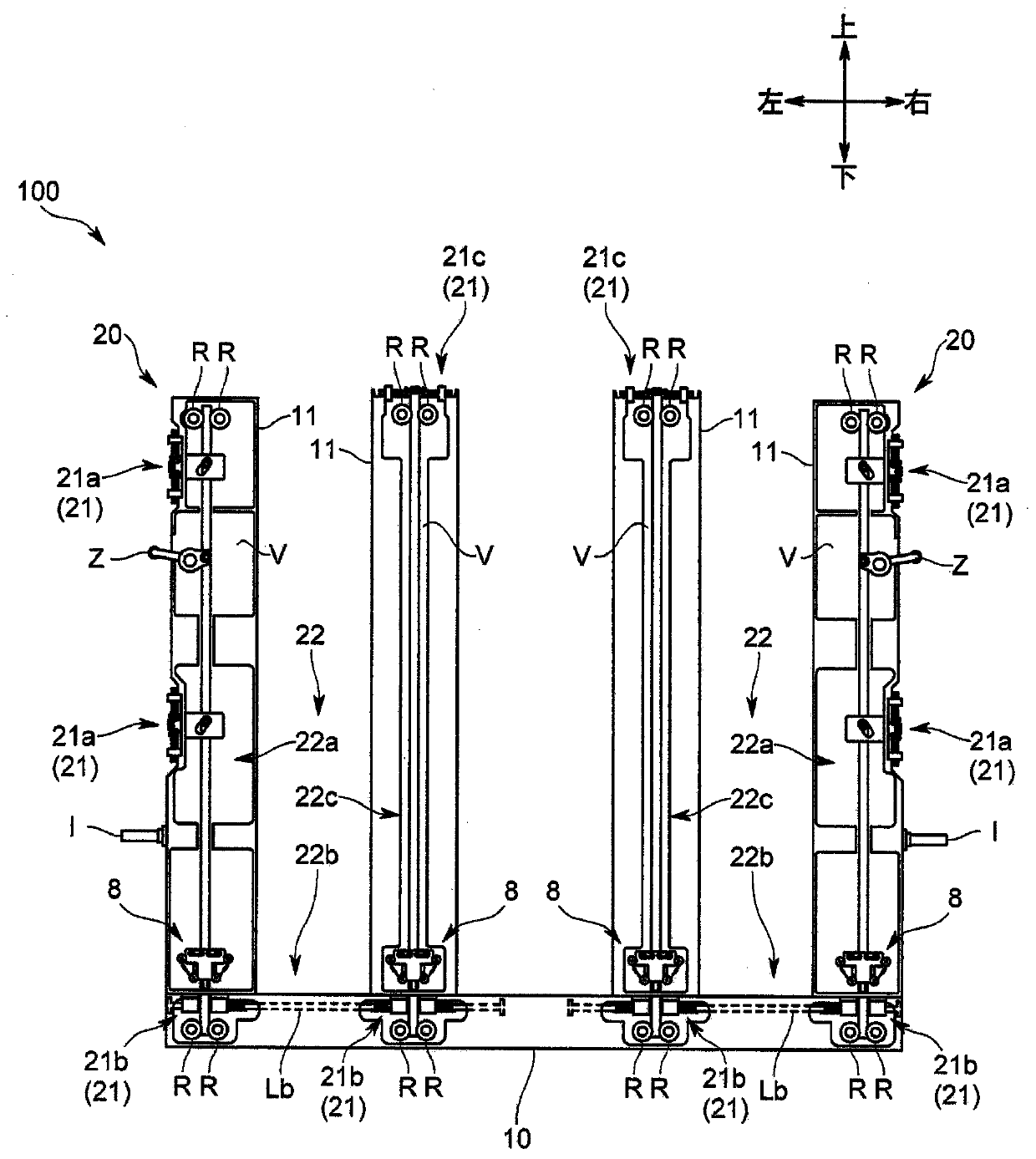

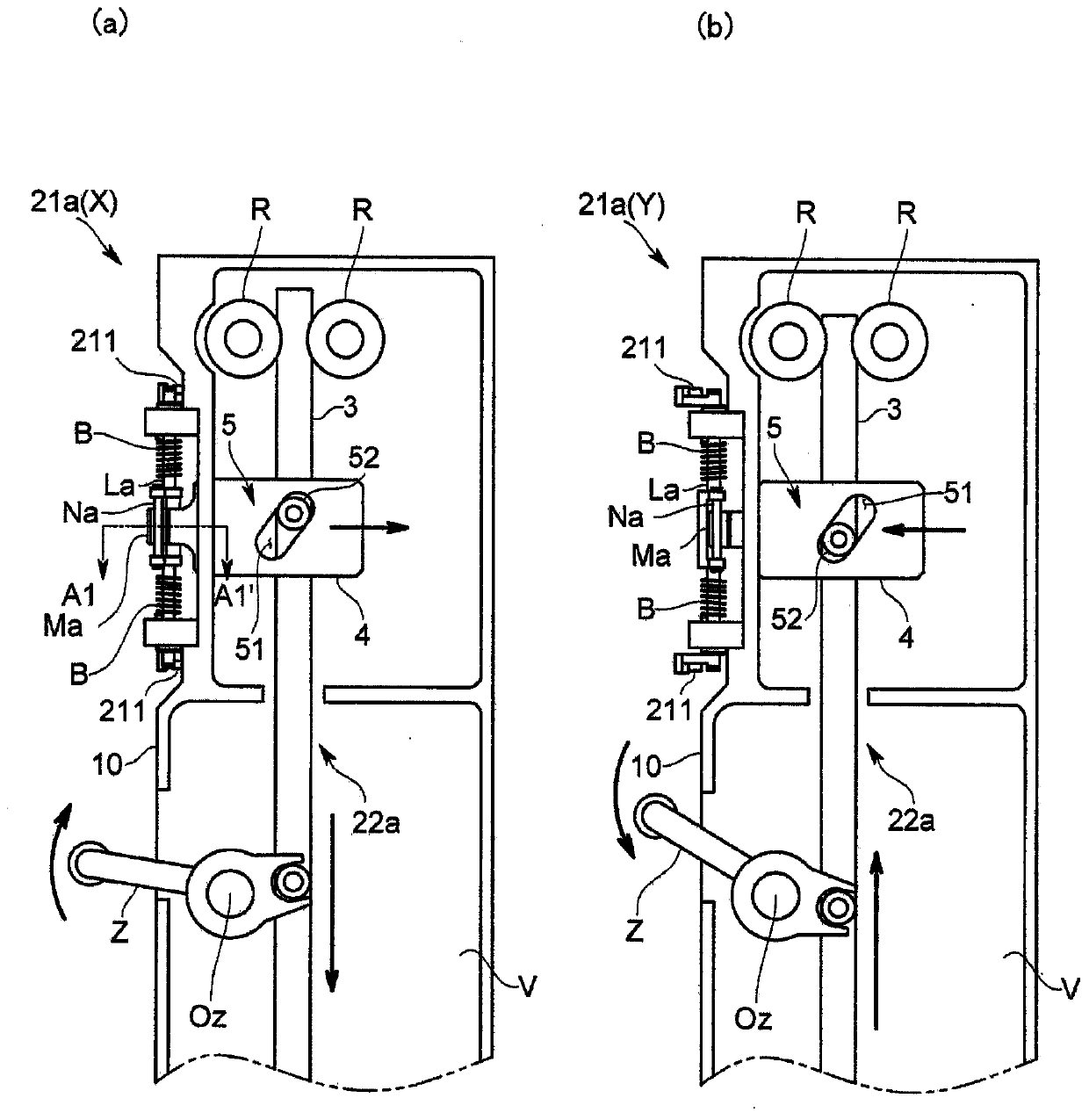

[0073] An embodiment of the substrate fixing device of the present invention will be described below with reference to the accompanying drawings.

[0074] The substrate fixing device 100 of the present embodiment is, for example, used in an ion beam irradiation device and fixes a substrate W belonging to a processing object, and as figure 1 and figure 2 As shown, it includes a platform 10 on which a substantially rectangular thin-plate substrate W is placed, and a clamping mechanism 20 ; the clamping mechanism 20 fixes the substrate W between the clamping mechanism 20 and the platform 10 .

[0075] The above-mentioned platform 10 transfers the substrate W between a transfer robot (not shown), and is configured to be rotatable about an axis I between a horizontal posture on which the substrate W is placed and a standing posture raised from the horizontal posture.

[0076] In addition, the horizontal posture here includes postures leaning from the horizontal direction, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com