Cotton-yarn mop

A cotton yarn and mop technology, which can be used in carpet cleaning, floor cleaning, cleaning equipment, etc., can solve problems such as unsanitary, troublesome, and unfavorable mopping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

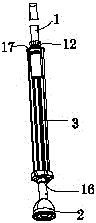

[0026] refer to Figure 1~Figure 6 , a cotton yarn mop, comprising a mop rod 1, a connector 2 connected to the lower end of the mop rod 1, cotton yarn as a wiper, the mop rod 1 is covered with a lift cover 3, and the mop rod A one-way transmission device is arranged between 1 and the lifting sleeve 3, and the one-way transmission device enables the lifting sleeve 3 to rotate in one direction on the mop rod 1.

[0027] The lifting sleeve 3 is covered with a gripping sleeve 4, the gripping sleeve 4 can slide axially on the lifting sleeve 3, and the gripping sleeve 4 and the lifting sleeve 3 cannot be rotated relative to each other . The specific cooperation mode between the gripping sleeve 4 and the lifting sleeve 3 in this embodiment is as follows: the lifting sleeve 3 is provided with an axial positioning rib 5, and the gripping sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com