Workshop measuring structure for improving temperature balance efficiency

A technology of temperature balance and efficiency, applied in the field of measurement, can solve problems such as wasting time, achieve the effects of improving measurement efficiency, reducing constant temperature time, and improving temperature balance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

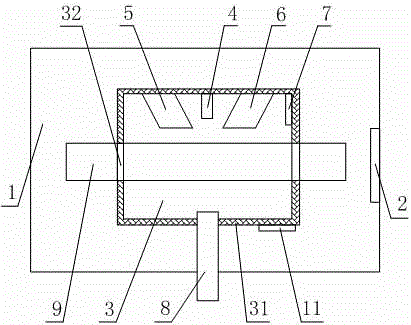

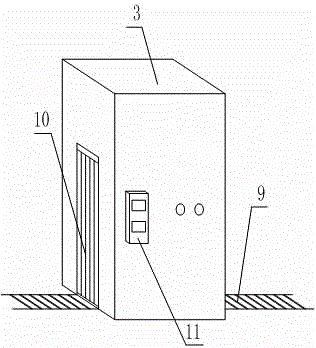

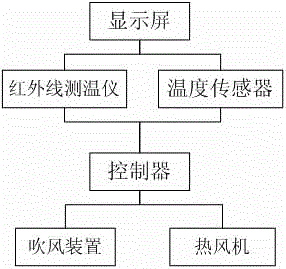

[0023] Such as Figure 1 to Figure 3 A measurement workshop structure for improving temperature balance efficiency is shown, including a measurement room 1 for placing measuring instruments, a temperature sensor 2 is arranged in the measurement room 1, a temperature control room 3 is also arranged in the measurement room 1, and through The conveyor belt 9 of the temperature-conditioning room 3, the intersection of the conveyor belt 9 and the body of the temperature-conditioning room 3 walls is provided with a door-shaped opening 32, and a PVC door curtain 10 is hung on the door-shaped opening 32; Aerated concrete block 31, the inner wall of the regulating chamber 3 is provided with an infrared thermometer 4 towards the center of the bottom of the regulating chamber 3, a hot air blower 5, and a blower 6, and a controller 7 is also arranged in the regulating chamber 3, and the regulating chamber 3 The outer wall is provided with a display screen 11, and the temperature sensor 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com