Automatic yarn drawing-in equipment

A yarn and equipment technology, applied in the field of yarn heddle equipment, can solve the problems of low production efficiency, high labor intensity and high operation requirements, and achieve the effects of high accuracy, reduced labor intensity and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

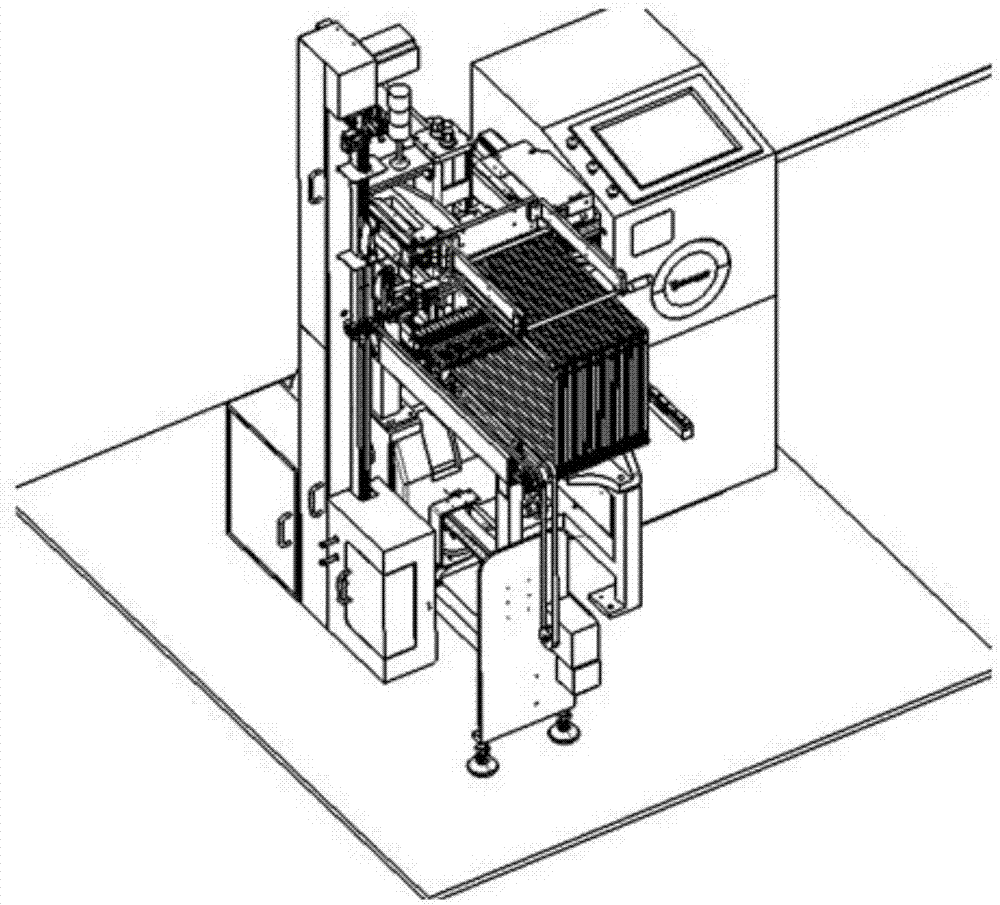

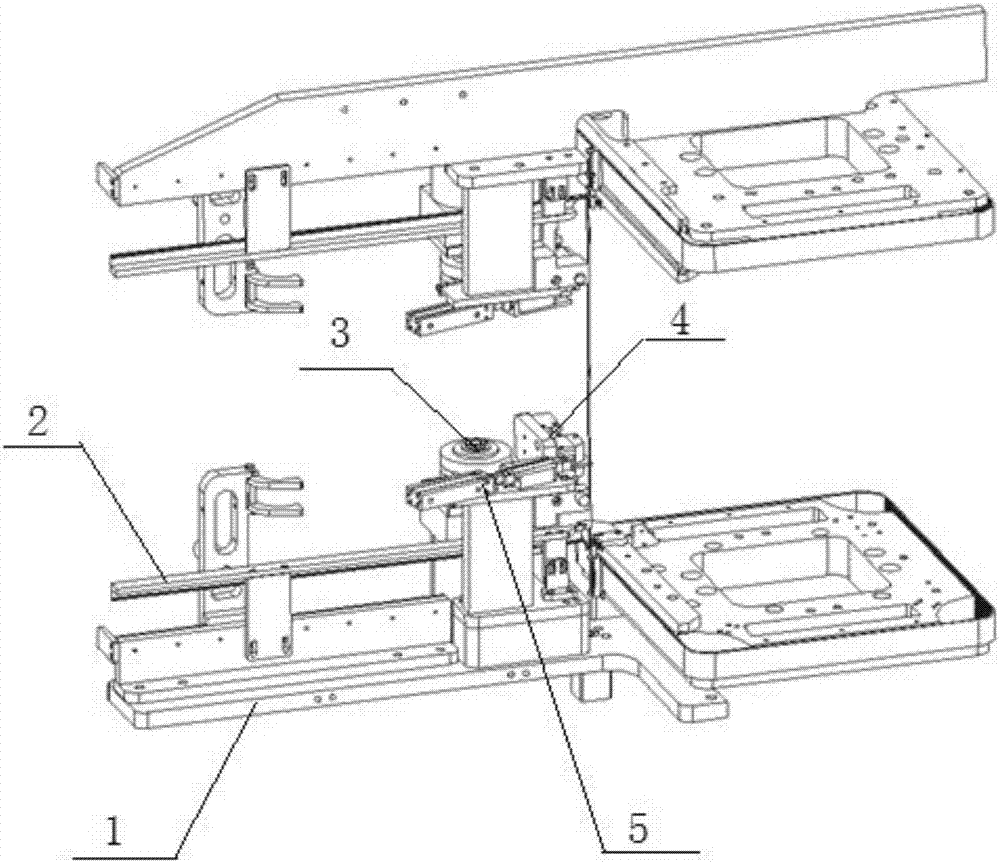

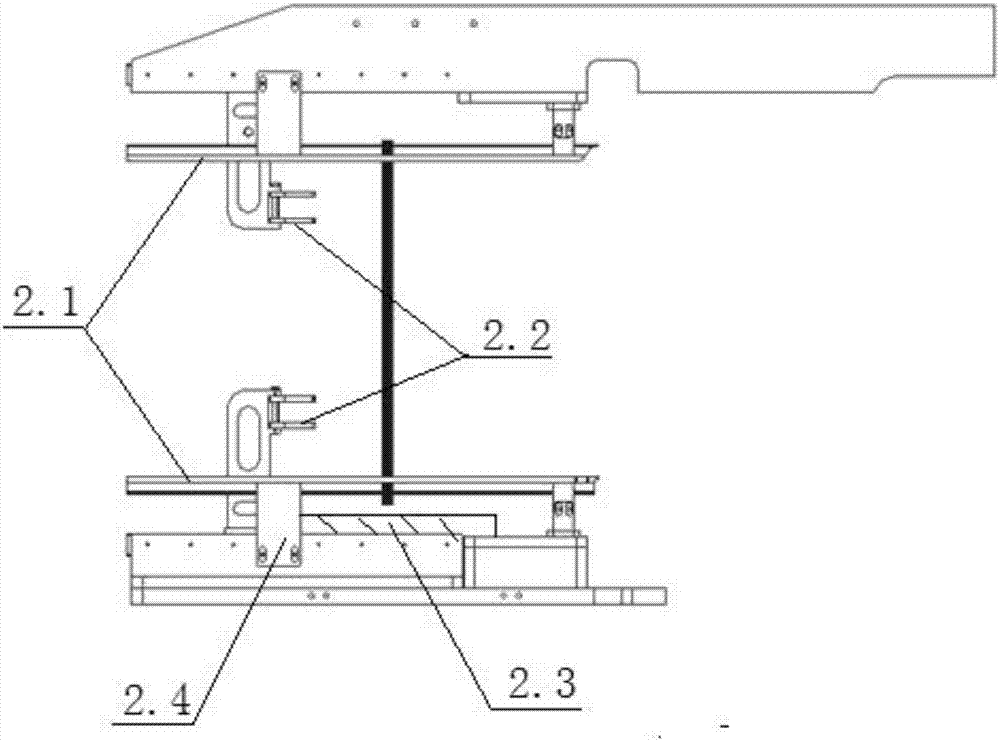

[0037] see figure 1 As shown, an automatic yarn heald drawing device in this embodiment includes a heald upper mechanism, a heald transmission mechanism, a yarn upper mechanism, a yarn hook mechanism, a reed feeding mechanism and a heald row mechanism installed on the frame; The above-mentioned heald mechanism is the initial station of the equipment, and the heald is stored in the heald storage place at one time, and then transported to the corresponding process position on the automatic heald threading to separate the single-piece heald; It is the end station of the equipment, and the heald runs through each station; the heald transmission mechanism transports the successfully separated heald to each station through transmission, and is the link connecting each station; the upper yarn The mechanism transports the equal-length yarn from the y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com