Automatic continuous double-strip packing and conveying system

A conveying system and conveyor belt technology, applied in the field of automation, can solve the problems of low packaging efficiency and packaging quality, and inability to pack and connect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing embodiment, the present invention will be further described:

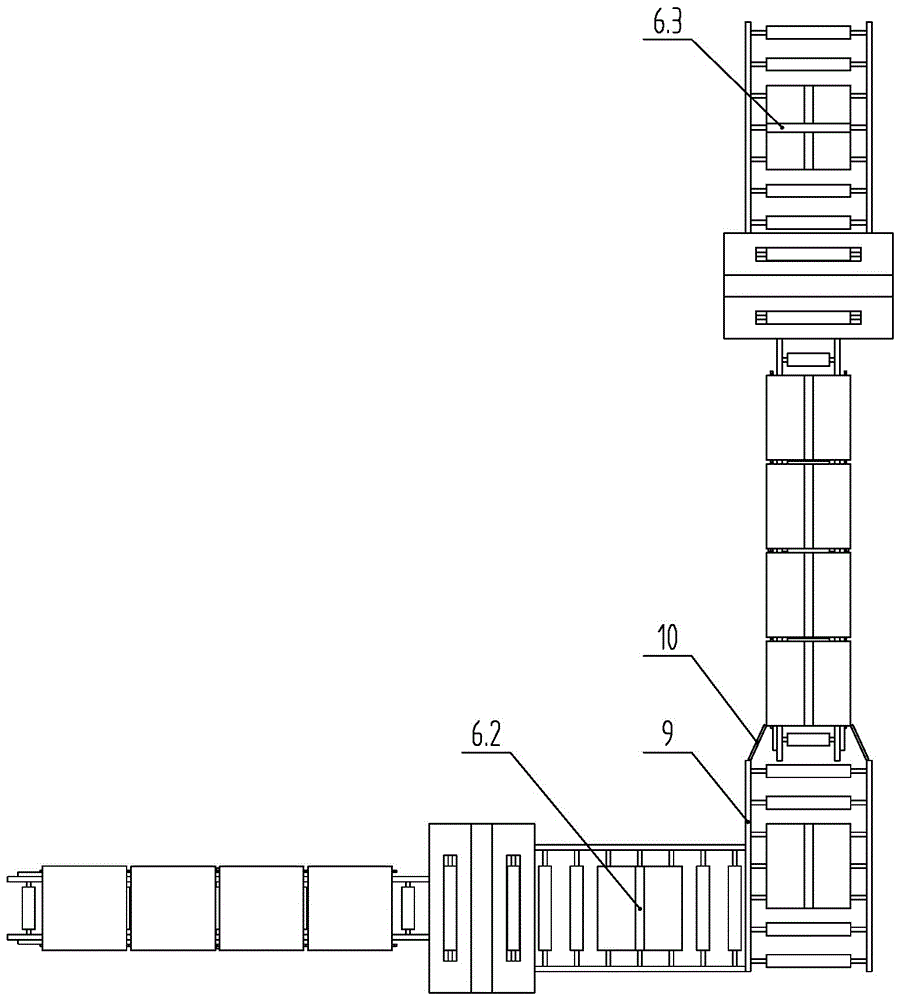

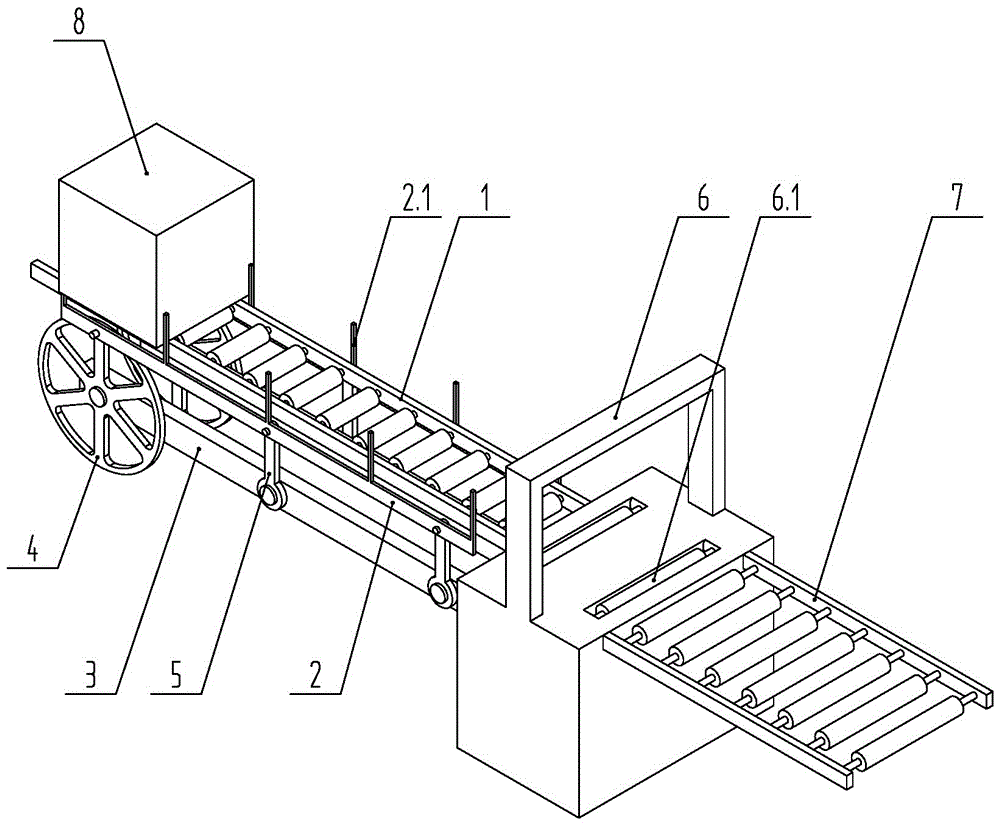

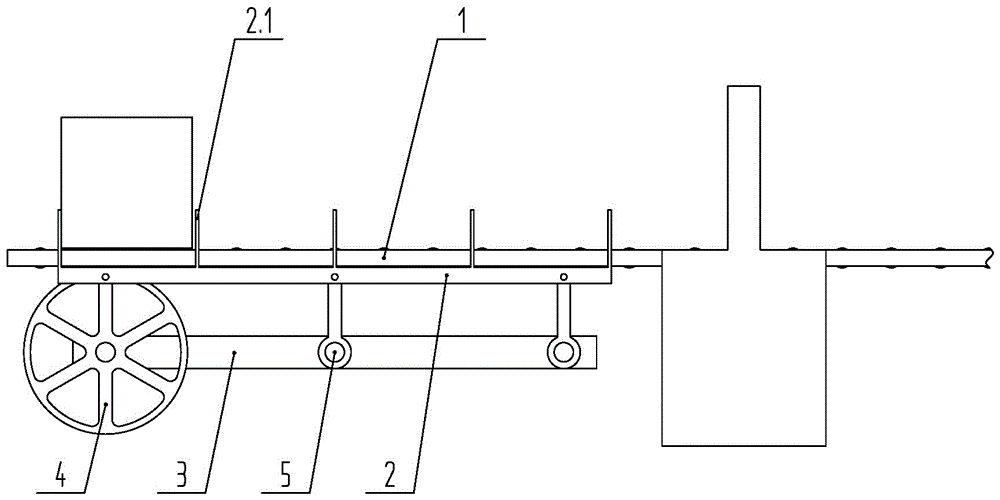

[0034] Such as Figures 1 to 4 As shown, an automatic continuous double-packing conveying system includes:

[0035] The first packaging and conveying mechanism is used to pack the first packaging strip 6.2 and transport it to the next link;

[0036] The second packaging and conveying mechanism is vertically arranged with the first packaging and conveying mechanism, and it is used to pack the second packaging strip 6.3 and transport it to the next link;

[0037] The connecting conveyor belt 9 with steering function is arranged between the first packing conveying mechanism and the second packing conveying mechanism and arranged in line with the second packing conveying mechanism for packing the packing box 8 with the first packing strip 6.2 After turning 90°, it is transported to the second packaging and conveying mechanism;

[0038] The guide plate 10 arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com