Salmon automatic processing production line and automatic processing method

An automatic processing and salmon technology, applied in fish processing, fish workbench, slaughtering, etc., can solve the problems of low production efficiency, long production process, pollution, etc., to improve working speed, production efficiency, and environmental protection standards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

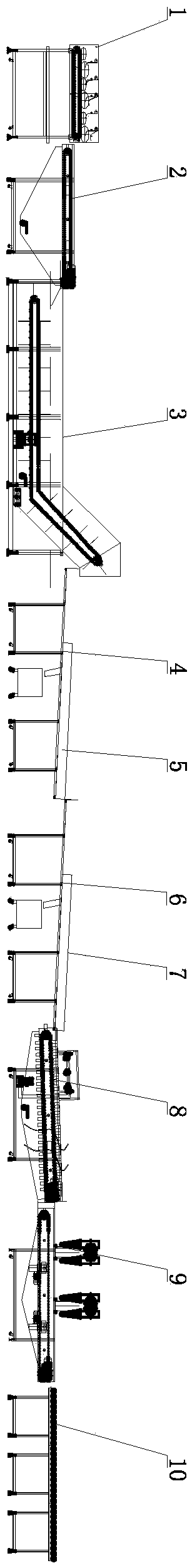

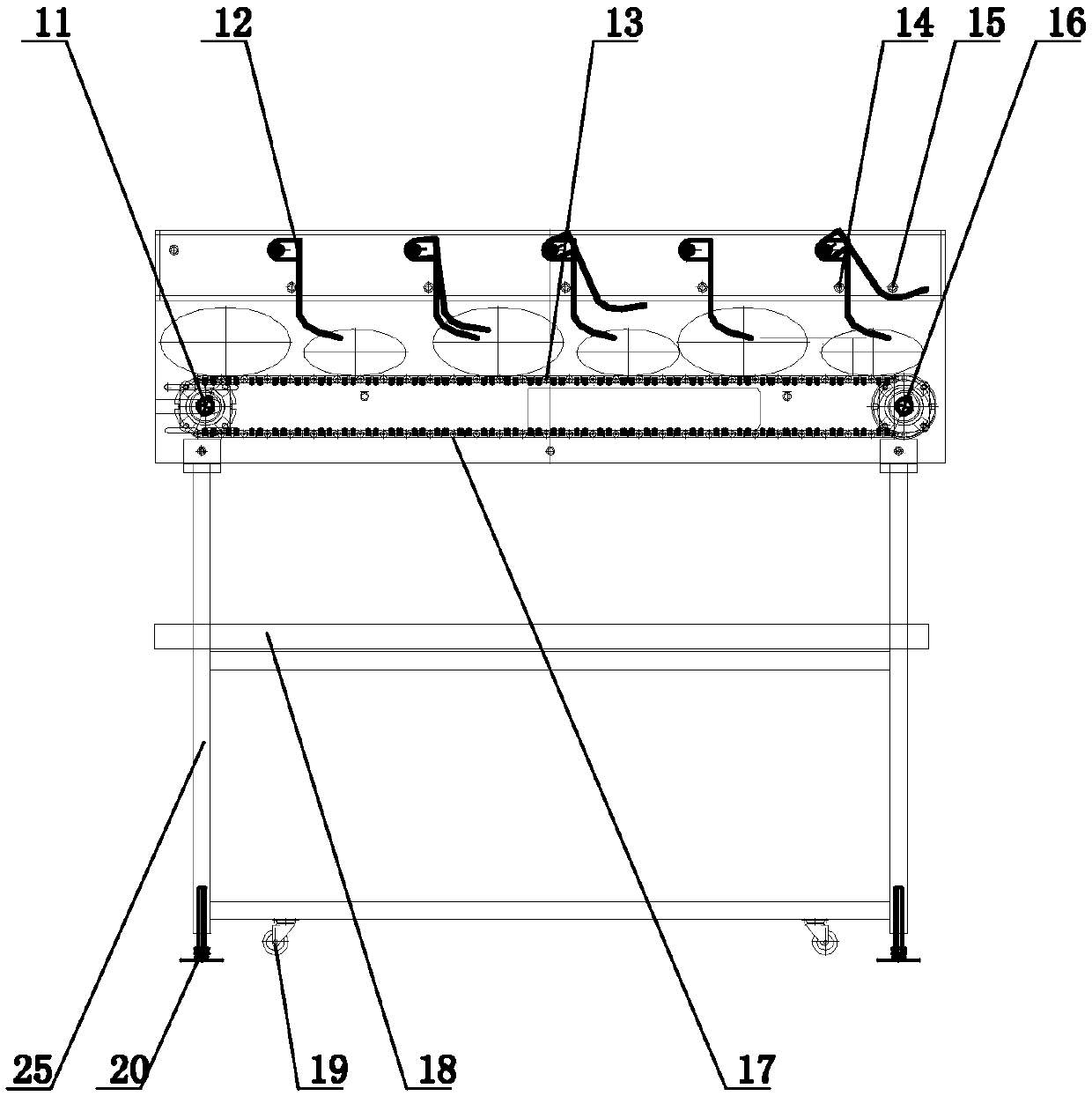

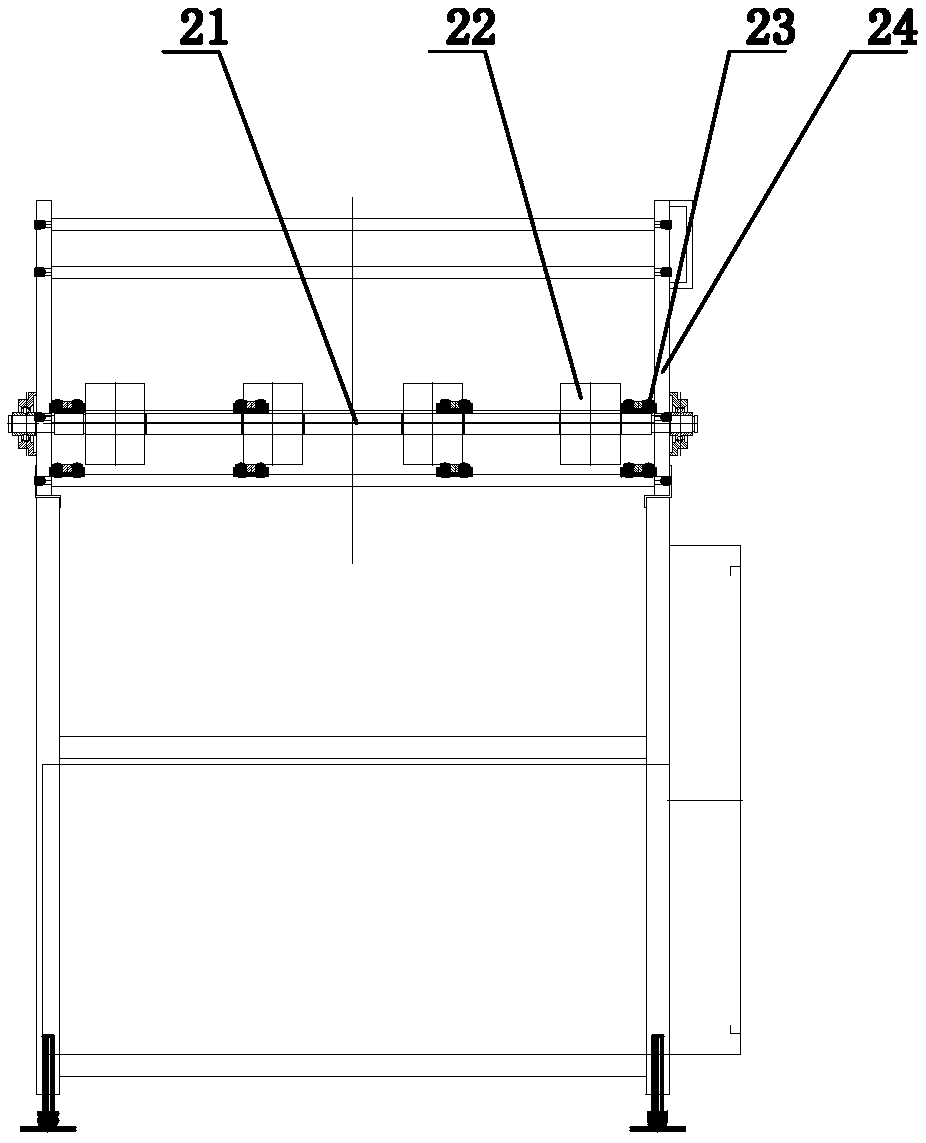

[0043] Below in conjunction with accompanying drawing, the embodiment of salmon automatic processing production line is described further:

[0044] Such as Figure 1-5 Shown, the salmon automatic processing production line of the present invention comprises following parts:

[0045] Fish suction and drainage system: The fish suction and drainage system includes a fish suction pump and a drainer. The fish suction pipe of the fish suction pump is located in the fish pond, and the fish sucked out by the fish suction pump are sent to the drainer for draining;

[0046] Electric shock system 1: The electric shock system 1 includes an electric shock device and a conveyor belt system 17. The starting point of the conveyor belt system 17 is docked with the outlet of the water drainer to catch the drained fish; the electric shock device includes a bracket 25, and the conveyor belt system 17 is arranged on the bracket 25 , be provided with the positive electrode 12 that is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com