An infant bottle assembly having a vented nipple

A pacifier and assembly technology, applied in the direction of rubber pacifiers, etc., can solve the problems of pacifier deformation, spitting up, baby colic and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

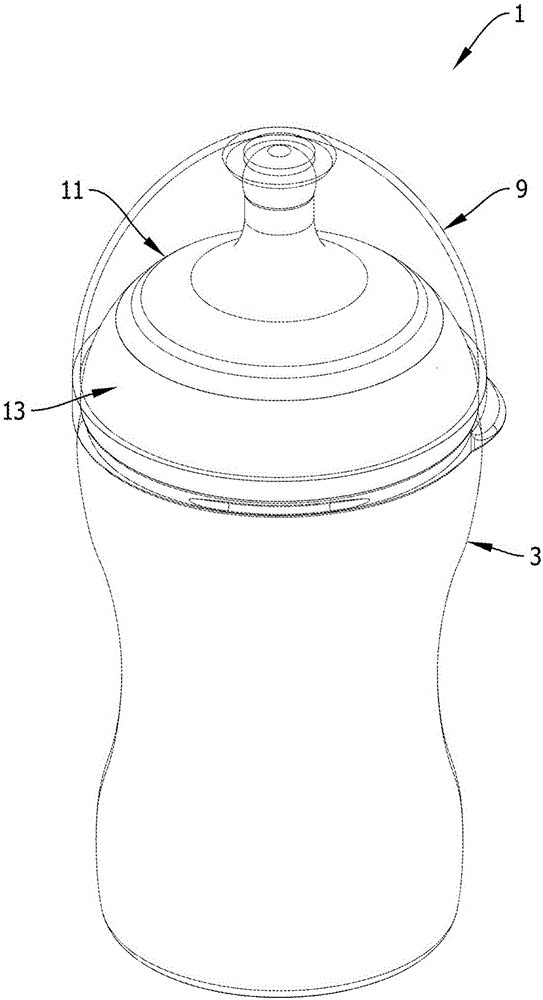

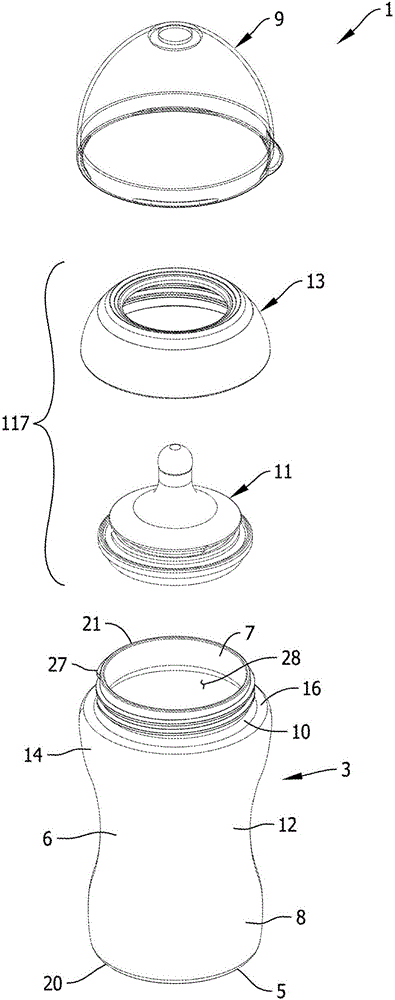

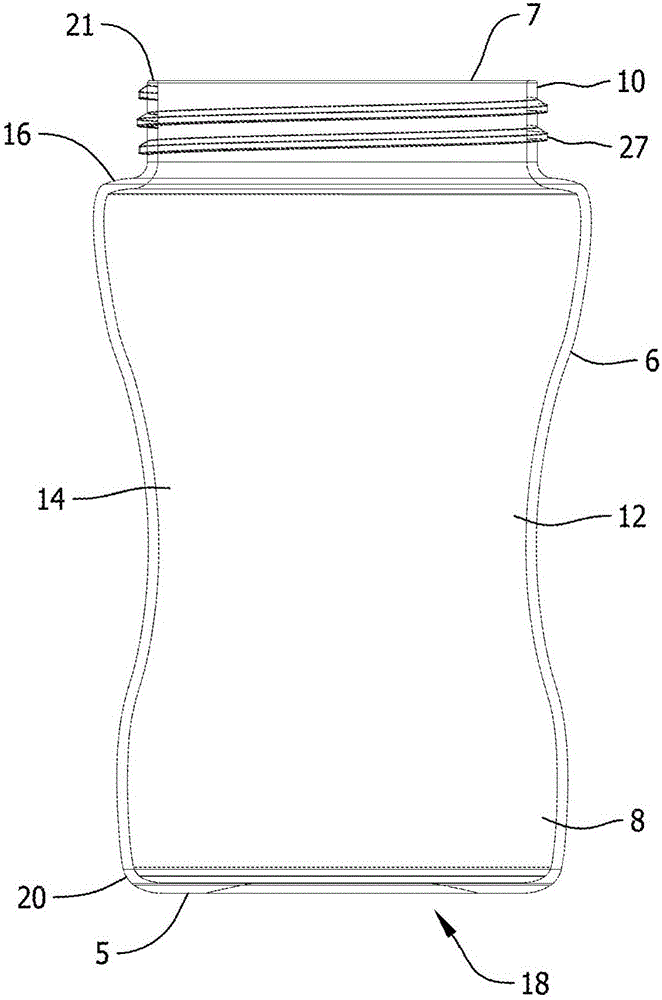

[0029] Referring now to the drawings and in particular to figure 1 and figure 2 , the bottle assembly with the vent nipple is uniformly denoted by 1. The bottle assembly 1 includes a bottle 3 , a cap 9 , a vent nipple 11 and a collar 13 . Each of the bottle 3 , cap 9 , teat 11 and collar 13 are collectively indicated by their respective reference numerals. Such as Figure 2 to Figure 5 As shown in , the bottle 3 has a closed bottom 5, an open top 7 and a generally cylindrical side wall 6 extending between the bottom 5 and the open top 7. The generally cylindrical side wall 6 includes a base 8 , a threaded top 10 , a middle 12 and an upper 14 . The middle part 12 extends between the base part 8 and the upper part 14 .

[0030] refer to Figure 2 to Figure 5 , the base 8 of the side wall 6 of the bottle 3 is substantially cylindrical and comprises a curved lower edge 20 which merges into the bottom 5 . The bottom 5 comprises a concave portion 18 which is smaller than the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com