Non-welding push-pull rod connecting structure of photovoltaic tracking support and solar tracker

A technology of solar tracker and connection structure, applied in the field of solar tracker, can solve the problems of not providing an ideal solution for push-pull rod connection, high cost, many processes, etc., and achieve the effect of easy on-site installation and adjustment, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

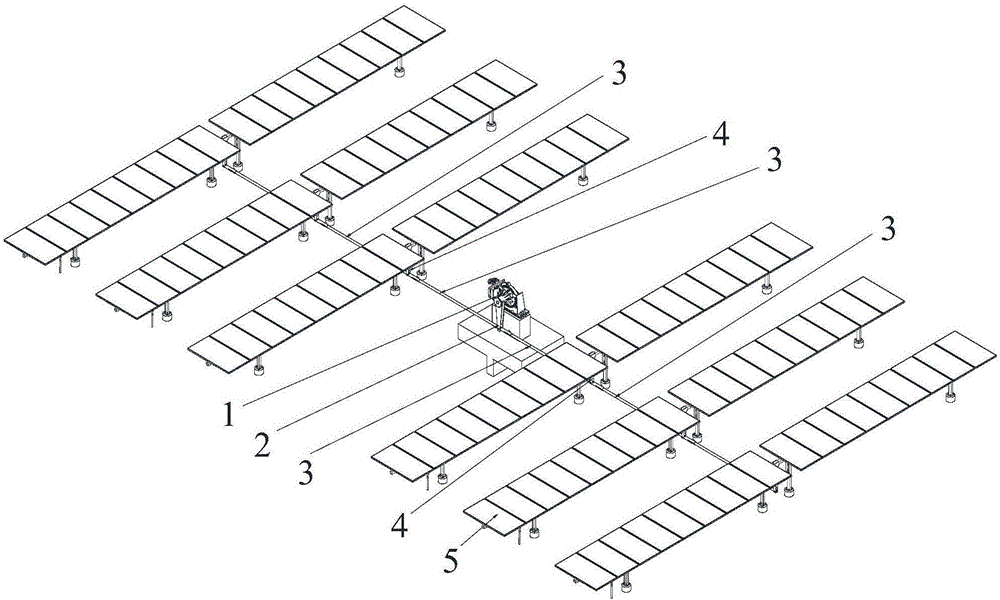

[0038] See Figure 5 and Image 6 , Solar automatic tracker can help solar photovoltaic or photothermal devices (such as photovoltaic panels, etc.) to better receive sunlight, to improve power generation efficiency, thereby reducing power generation costs. Among the existing automatic trackers, the linkage type parallel linkage mechanism has the advantages of simple structure, fewer driving components, and lower cost, and is widely used. The photovoltaic tracking bracket of the linked parallel link mechanism tracker is mainly composed of the driving device 1, the driving arm 2, the push-pull rod, the driven arm 4, and the component 5. The adjacent two rows of components are connected with the driven arm 4 through the push-pull rod to make The assembly 5 follows the rotation of the driving arm 2 to maximize solar energy and improve energy conversion efficiency.

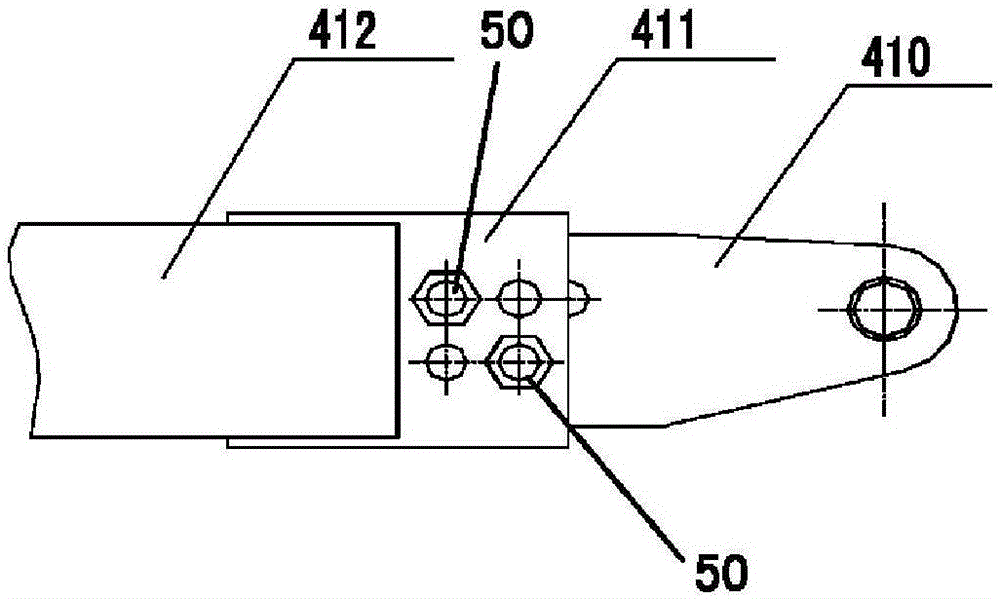

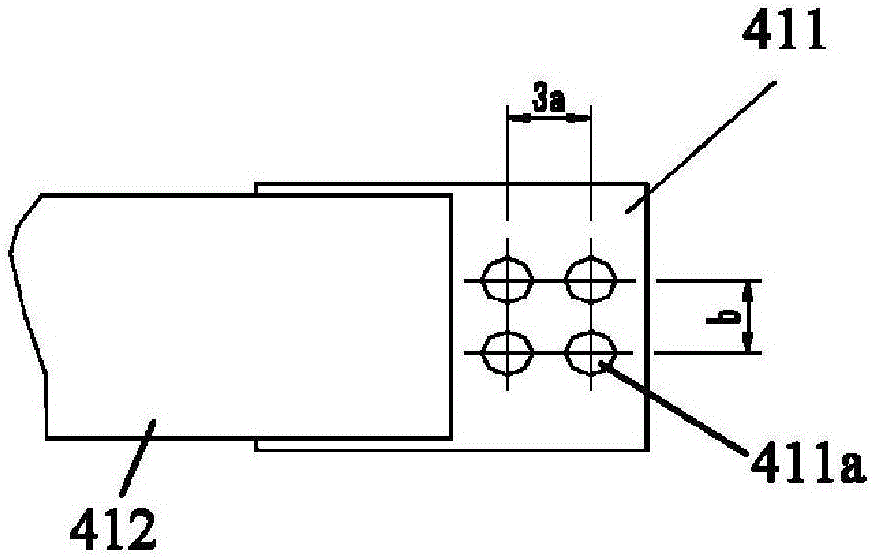

[0039] The main function of the push-pull rod is to transmit the tracking angle of the driving arm 2 to the driven arm ...

Embodiment 2

[0049] Please refer to Picture 11 , Picture 12 , Figure 13 and Figure 14 The structure of the solderless push-pull rod connection structure of the photovoltaic tracking bracket of Example 2 is basically the same as the structure of the solderless push-pull rod connection structure of the photovoltaic tracking bracket of Example 1, and the functional effects are basically similar. The difference lies in: The first pull rod 30, the second push rod 31, and the adjustable rod 32 are all tubular. The push rod 30, the second push rod 31, and the adjustable rod 32 of the second embodiment are all rectangular.

[0050] Combining the two embodiments, it can be seen that the beneficial effects of the present invention are:

[0051] 1. The solar tracking array adopts the same push-pull rod structure, which is easy to realize standardized production in the factory;

[0052] 2. Both the push-pull rod and the adjustment rod are made of profiles, and the joints at the joints do not need to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com