Automatic arrow belt threading mechanism

A driving mechanism, arrow belt technology, applied in textile, textile and papermaking, weaving auxiliary equipment and other directions, can solve the problems of high operation requirements, high labor intensity, low production efficiency, etc., to reduce labor intensity, improve work efficiency, The effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

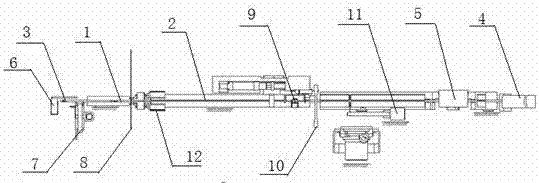

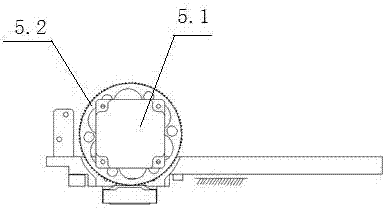

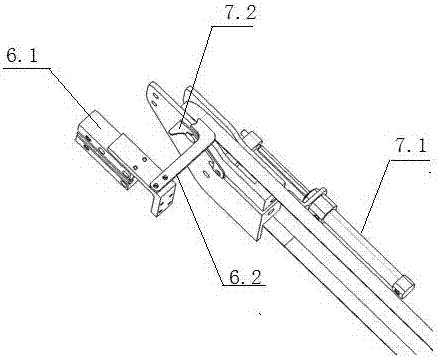

[0026] see figure 1 As shown, an automatic arrow belt threading mechanism in this embodiment includes an arrow belt groove 2 in which the arrow belt 1 moves back and forth, and the head of the arrow belt 1 is provided with an arrow hook 3, and the arrow hook 3 will The single yarn sent by the weft feeder is hooked, and the tail is located in the arrow belt bag 4, and the arrow belt 1 in the arrow belt bag 4 realizes rapid linear reciprocation in the arrow belt groove 2 under the action of the arrow belt driving mechanism 5 Movement, the head of the arrow belt groove 2 is provided with a head yarn pressing device 6 that controls the yarn trend, facilitates the arrow hook to hook the yarn, and controls the yarn that successfully passes through the heddle to escape from the arrow belt groove 2. The upper part of the yarn beating mechanism 7 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com